Combing mechanism for full-automatic underground parking lot and use method

An underground parking lot, fully automatic technology, which is applied to the buildings, building types, buildings and other directions where cars are parked. It can solve the problems of inability to correct the car position, high lubrication requirements, and high operating noise, so as to achieve convenient and fast maintenance and lubrication. The effect of low requirements and reduced failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings, but it should be pointed out that the implementation of the present invention is not limited to the following embodiments.

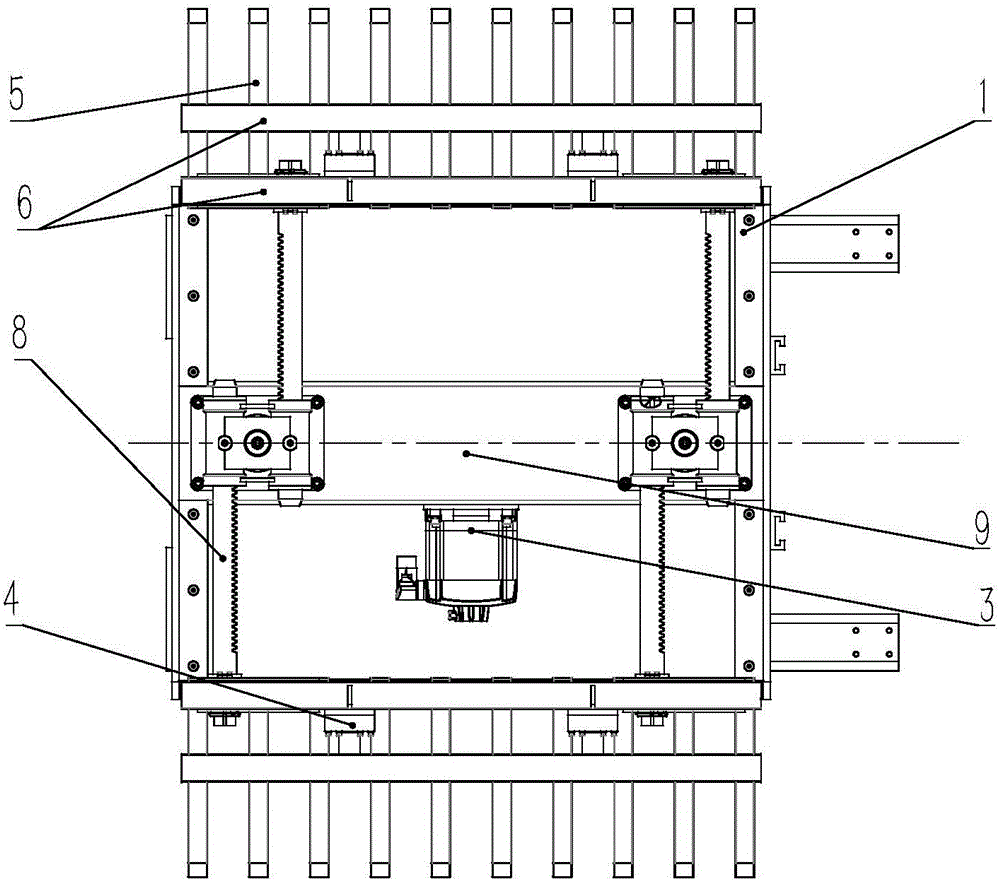

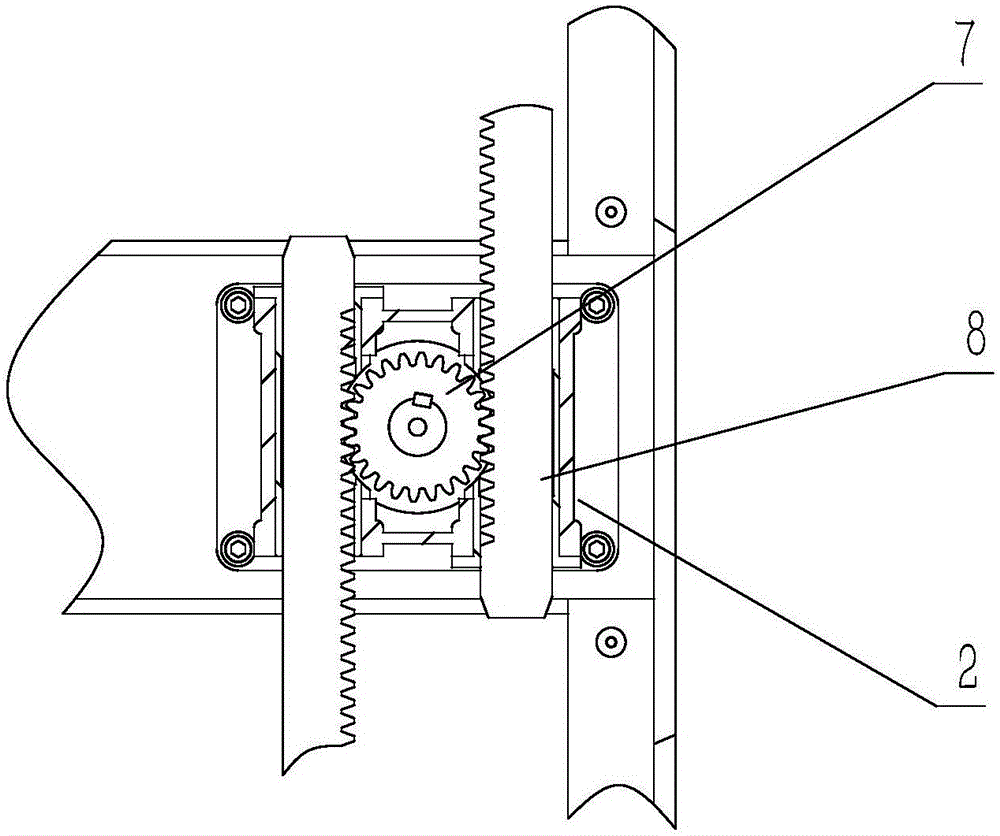

[0022] See figure 1 , figure 2 , a comb mechanism for a fully automatic underground parking lot, including a box body 1, a servo motor 3, a reducer 9, a gear 7, a rack 8, and a complete vehicle part 4, and the output end of the servo motor 3 passes through the reducer 9 and the gear 7 is connected, both sides of the gear 7 mesh with two racks 8, and the ends of the racks 8 are fixedly connected with the vehicle parts 4. There are two gears 7, and the rack 8 is connected with the end of the whole vehicle part 4. The gear 7 drives the rack 8 to move in translation in the guide seat 2. The speed reducer 9 can realize the purpose that a servo motor 3 drives two gears 7 to rotate at the same time.

[0023] The whole vehicle part 4 includes a comb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com