Advanced water prevention construction process for post-cast strip of side wall of basement

A construction technique and technology of post-pouring tape, which is applied in the field of advanced waterproof construction technology of post-pouring tape on the side wall of the basement, can solve the problems of long construction period, large construction impact, and easy collapse, and achieve short construction period, low construction difficulty, and The effect of high wall strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

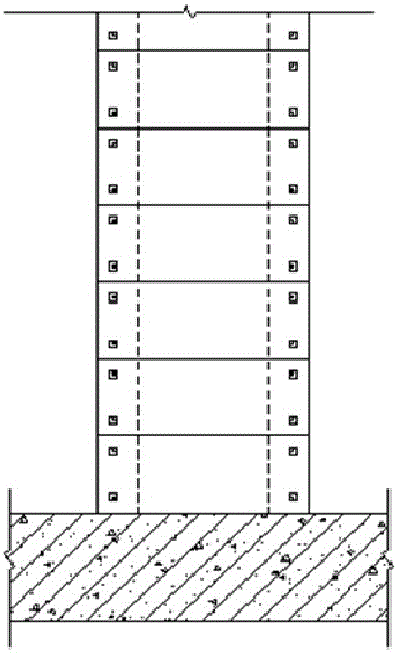

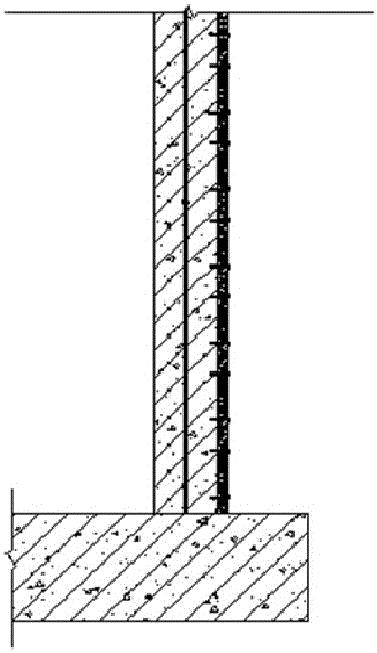

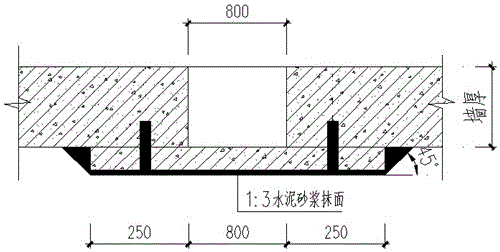

[0024] Such as figure 1 , figure 2 , image 3 As shown, a basement side wall post-pouring tape advanced waterproof construction technology, including the following steps:

[0025] (1) Remove the formwork and clean the post-casting belt: Use steel wire mesh on both sides of the post-casting belt as the formwork support at the end of the post-casting belt. The slurry and excess concrete in the post-casting zone must be chiseled clean and straightened, and all the original concrete garbage should be cleaned up;

[0026] (2) Reinforced concrete baffle prefabrication: the length of the baffle is based on the width of the post-casting belt plus a support length of 250mm on each side, that is, the actual width of the post-casting belt + 500mm, the width of the baffle is 500mm, the thickness is 80mm, the diameter is 8mm, and the length 150mm steel bar, the concrete strength grade is C25. When the baffle is prefabricated, two installation holes with a diameter of 14mm are reserved...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com