Bridge expansion joint covering mechanism provided with sound insulation cover

A sound-proof cover and expansion joint technology, applied in bridges, bridge parts, bridge construction and other directions, can solve the problems of damage, damage to the road substrate, installation and disassembly costing a lot of manpower and time, and achieve the effect of easy installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

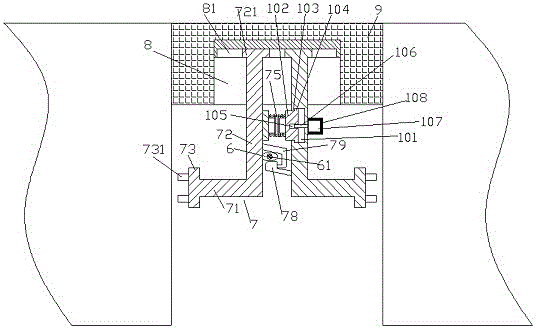

[0009] Combine below Figure 1-3 The present invention will be described in detail.

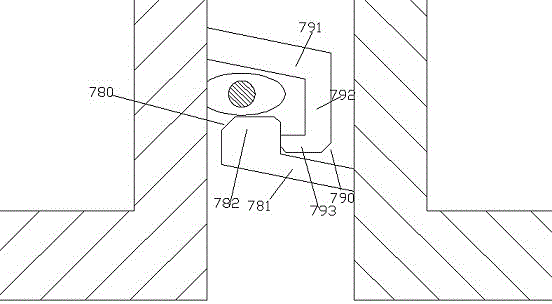

[0010] According to an embodiment, a bridge expansion joint covering mechanism with a soundproof cover is used to cover the road surface of the bridge expansion joint, including a rubber body 9 flush with the level of the bridge road surface, and a rubber body 9 located inside the rubber body 9 A support body 8, and two extension supports 7 that can move toward and away from each other in the support body 8 and are structurally symmetrical to each other, wherein each of the two extension supports 7 includes a The horizontal extension head 721 sliding horizontally in the chute 81 of the support body 8 , the vertical extension 72 connected to the horizontal extension head 721 , and the lower end of the vertical extension 72 connected to the adjacent bridge The supporting arm 71 extended by the structure, wherein, the ends of the two extended supports 7 are provided with a supporting plate 73 f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com