Low-yellowing hydrophilic finishing agent and preparation method thereof

A hydrophilic finishing agent, low-yellowing technology, applied in the direction of fiber treatment, improved hand fiber, textiles and papermaking, etc., can solve the problem of increasing the flow viscosity of aminohydrocarbyl polyorganosiloxane and affecting the softness of aminohydrocarbyl polyorganosiloxane. It can improve the chemical stability, strengthen the flexibility and reduce the viscosity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The preparation method of low-yellowing hydrophilic finishing agent of the present invention comprises the following steps:

[0047] 1) Take corresponding raw materials according to the above proportioning ratio for subsequent use;

[0048] 2) Preparation of aminohydrocarbyl polyorganosilane:

[0049] a: Under normal pressure, add polysiloxane monomer and aminoethyl-aminopropyl-methyldialkoxysilane to a flask equipped with a stirrer and a thermometer, heat to 80-110°C while stirring, and react Time 50-130 minutes;

[0050] b: Add an alkalizing agent to the flask after the reaction in step a is completed, and keep the temperature at 80-110°C for 3-5 hours;

[0051] c: naturally cool the mixture obtained in step b to room temperature, add 0.05-0.1 part of acidifying agent to neutralize, and obtain aminohydrocarbyl polyorganosilane;

[0052] 3) Preparation of modified aminohydrocarbyl polyorganosiloxane:

[0053] d: Add 100 parts of aminoalkyl polyorganosilane and orga...

Embodiment 1

[0063] The low-yellowing hydrophilic finishing agent of the present invention includes polysiloxane monomer, aminoethyl-aminopropyl-methyldialkoxysilane, isopropanol, acrylic acid, isomeric C13 alcohol ether 5EO, potassium hydroxide and acetic acid, the above components are calculated in parts by mass: 100 parts of polysiloxane monomer; 2 parts of aminoethyl-aminopropyl-methyldialkoxysilane; 5 parts of isopropanol; 1 part of acrylic acid ; 5 parts of isomeric C13 alcohol ether 5EO; 0.05 parts of potassium hydroxide; 0.15 parts of acetic acid.

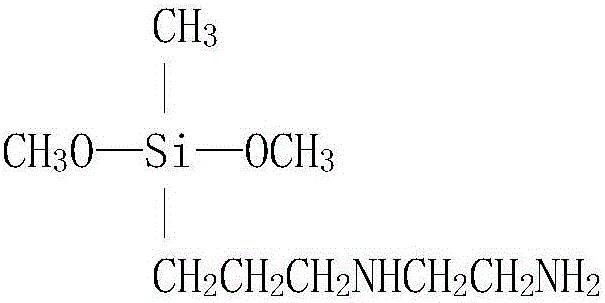

[0064] The molecular structural formula of aminoethyl-aminopropyl-methyldialkoxysilane is:

[0065]

[0066] The preparation method of low-yellowing hydrophilic finishing agent of the present invention comprises the following steps:

[0067] 1) Take corresponding raw materials according to the above proportioning ratio for subsequent use;

[0068] 2) Preparation of aminohydrocarbyl polyorganosilane:

[0069] a: Under normal pressu...

Embodiment 2

[0082]The low-yellowing hydrophilic finishing agent of the present invention includes polysiloxane monomer, aminoethyl-aminopropyl-methyldialkoxysilane, isopropanol, ethanol, ethylene glycol monobutyl ether, dipropylene glycol, Acrylic acid, ethylene carbonate, isomeric C13 alcohol ether 5EO, isomeric C13 alcohol ether 7EO, branched fatty alcohol polyoxyethylene ether 7EO, branched fatty alcohol polyoxyethylene ether 9EO, potassium hydroxide, hydroxide Sodium, acetic acid and propionic acid, the above components are calculated in parts by mass: 100 parts of polysiloxane monomer; 13 parts of aminoethyl-aminopropyl-methyldialkoxysilane; 10 parts of isopropanol ; 10 parts of ethanol; 10 parts of ethylene glycol monobutyl ether; 10 parts of dipropylene glycol; 3 parts of acrylic acid; 2 parts of ethylene carbonate; 4 parts of isomeric C13 alcohol ether 5EO; 4 parts of fatty alcohol polyoxyethylene ether 7EO; 4 parts of branched fatty alcohol polyoxyethylene ether 9EO; 0.1 part of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com