A water-permeable film production device

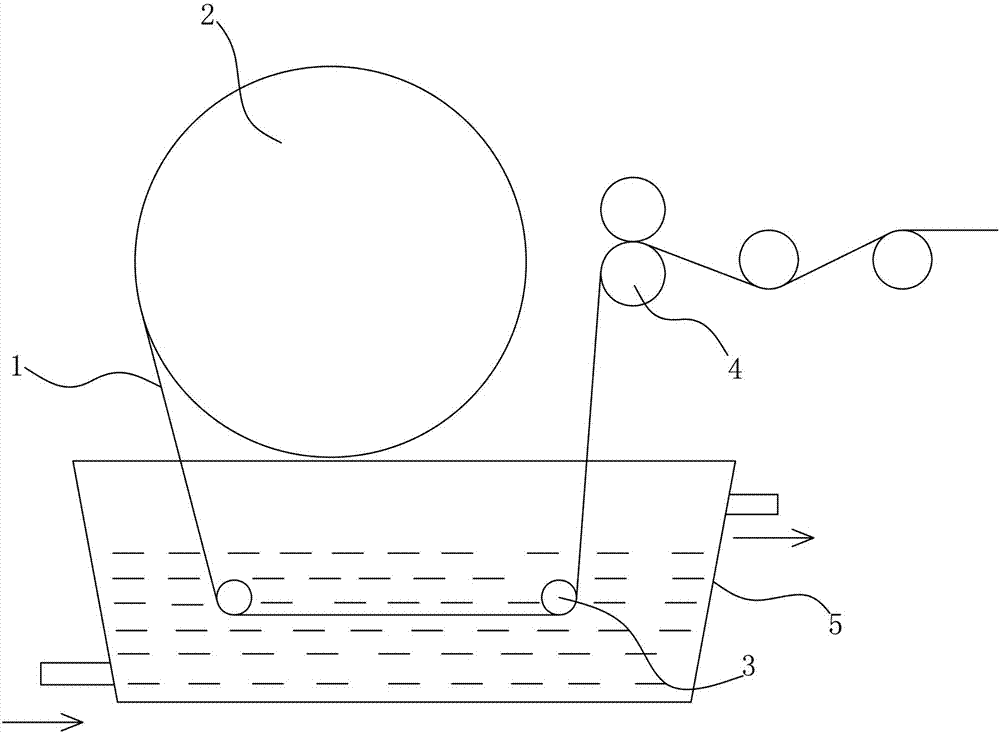

A production device and water permeable technology, applied in applications, household appliances, flat products, etc., can solve problems such as uneven water temperature, water marks on the surface of the film, unstable peeling points, etc., and achieve the effect of consistent water temperature and clean water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

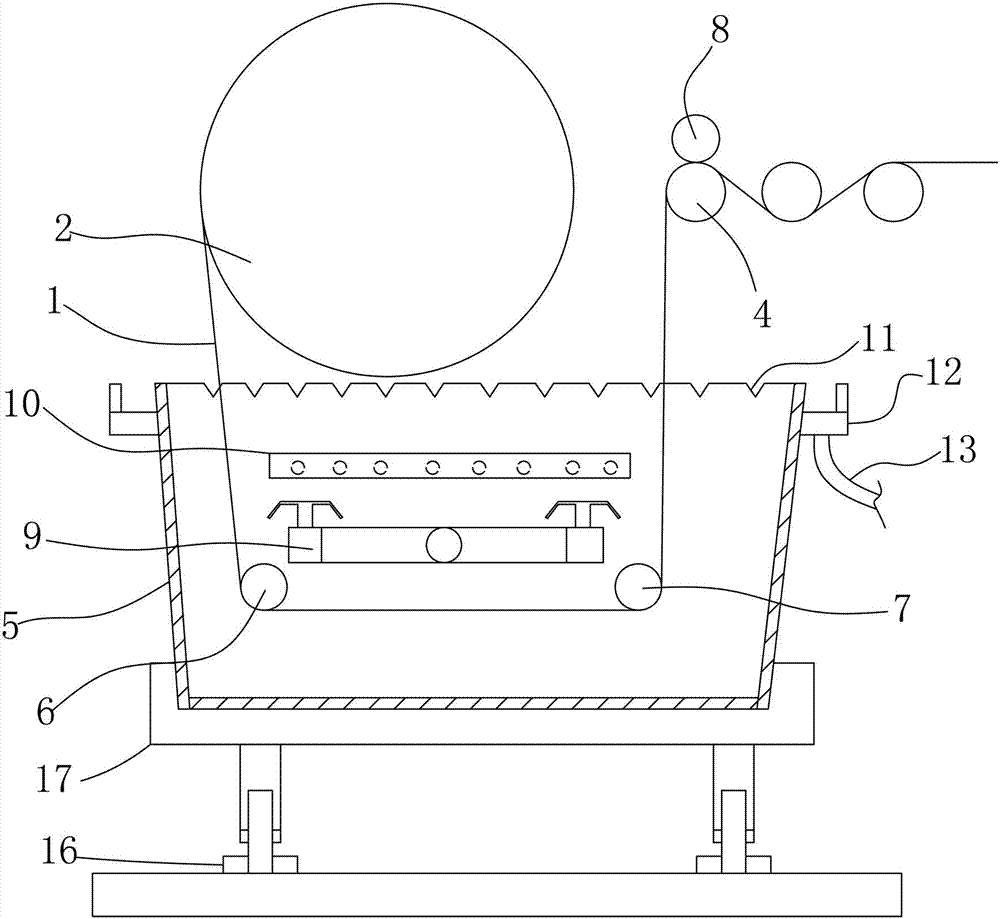

[0025] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

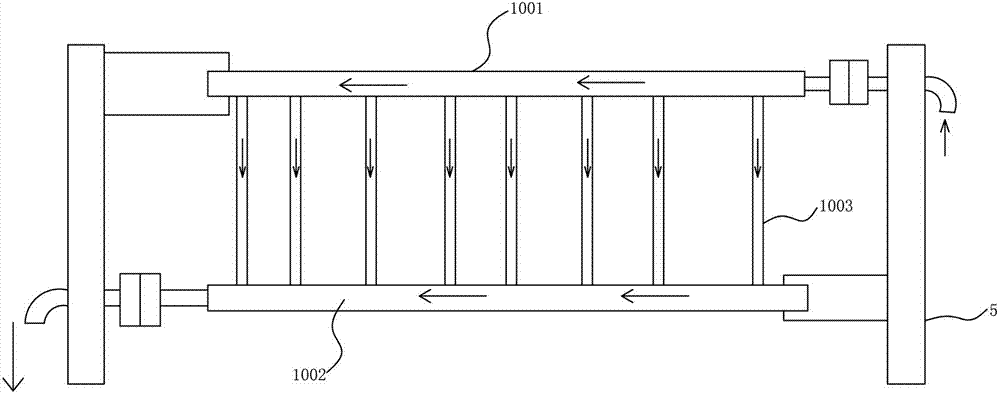

[0026] Depend on Figure 2 to Figure 8 Provide, the technical scheme of the present invention is, comprise ground track mobile trolley 17, pool 5 and squeeze water device, ground rail mobile trolley 17 can move back and forth along the ground rail that is fixed on the frame, and pool 5 is fixed on ground rail mobile trolley On the platform 17, there is a set of traction device at the outlet of the pool, which can also be used for squeezing water.

[0027] The ground rail 16 is actually a track laid on the bottom plate connected to the machine wall.

[0028] The mobile trolley 17 can move forward and backward along the longitudinal direction of the calender on the ground rail 16. When the water-permeable membrane is produced, the mobile trolley 17 is pushed in together with the water-permeable device on it, and released ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com