Forging method for efficiently healing steel ingot internal hole type defects by using small pressure

A technology of internal holes and pressure, which is applied in the field of forging, can solve the problems of axis looseness and forged steel ingots, and achieve the effects of reducing scrap, increasing internal strain of blanks, and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

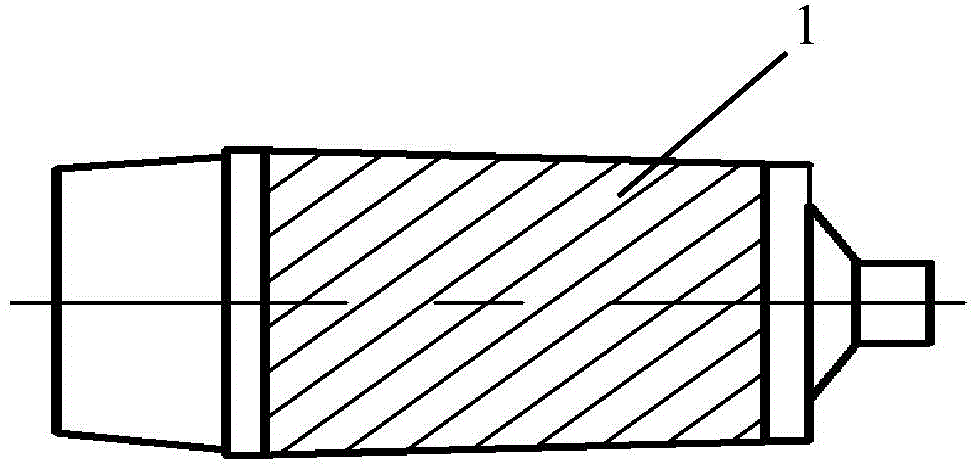

Image

Examples

Embodiment

[0041]In this embodiment, three steel ingots are used, each weighing about 8 tons, the material is 27SiMn, and the heating temperature of the blank before forging is 1200°C. The dendrites of this steel are very developed during the solidification process, and it is easy to form large shrinkage cavity and loose defects in the core. The press used is 2,000 tons, and there is no upsetting plate, so the upsetting process cannot be used for the steel ingot, and it can only be drawn directly. According to the forging method proposed by the present invention, use 400mm wide upper and lower flat anvil forging. First, pre-drawing is carried out, and the cross-section of the steel ingot is drawn to a square of 600 mm (that is, the cross-section is a square with a side length of 600 mm). Afterwards, two passes of unidirectional large deformation are carried out. The reduction in the first pass is 150mm, and the reduction in the second pass is 90mm. After pressing the billet into a flat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com