Vertical agitator

The technology of a vertical mixer and agitator is applied in kitchen utensils, home utensils, applications, etc., which can solve the problems of high precision requirements of parts, large product shape and high cost, and achieve the effect of improving product life, compact structure and large torque.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings.

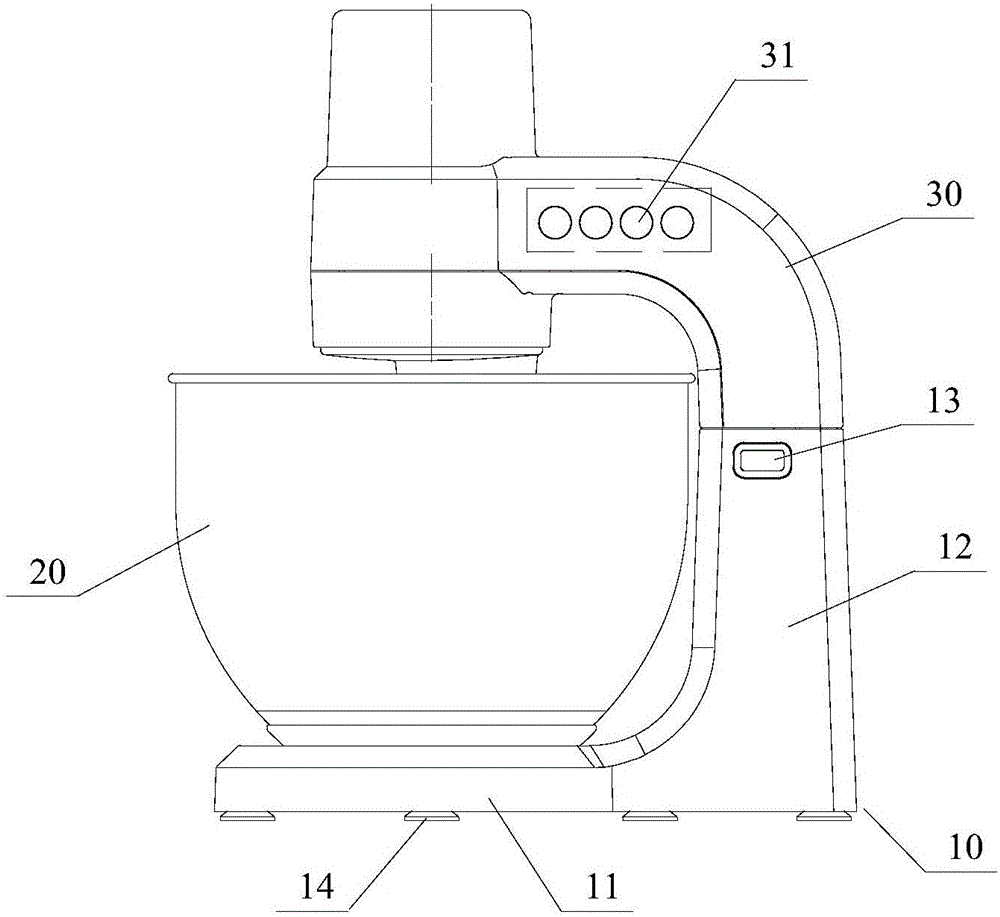

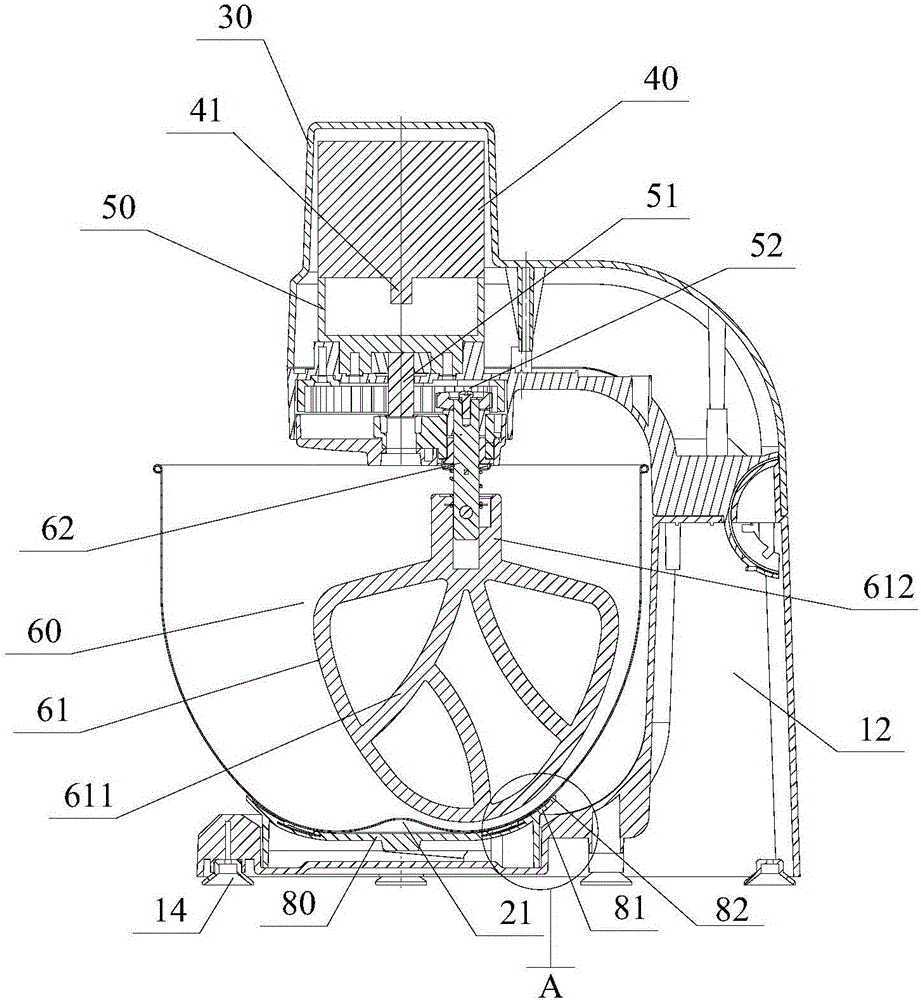

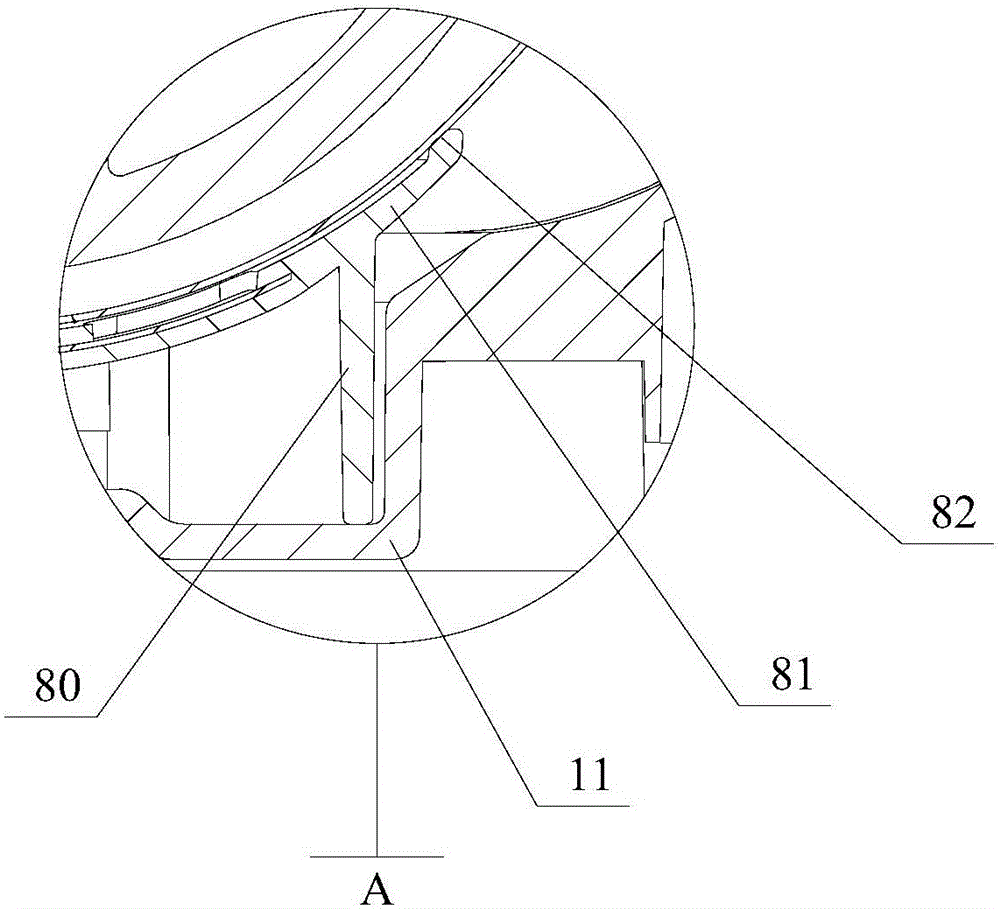

[0025] Such as figure 1 , figure 2 As shown, the present invention provides a vertical mixer, including a base composed of a base 10 and a machine head 30, the machine head 30 is provided with a driving mechanism for driving the stirring assembly, and the driving mechanism includes a DC motor 40 and a planetary gear reduction A device 50, wherein the DC motor 40 is arranged vertically, and compared with the currently commonly used AC motors, the DC motor 40 has low noise, low energy consumption, and large torque.

[0026] The middle part of the planetary gear reducer 50 is provided with the axle 51 of the sun gear. The axle 51 of the sun gear is arranged in the middle of the sun gear. The outer side of the sun gear is provided with a plurality of planetary gears 52 meshing and rotating around the sun gear. The axle 51 of the sun gear It is connected with the outpu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com