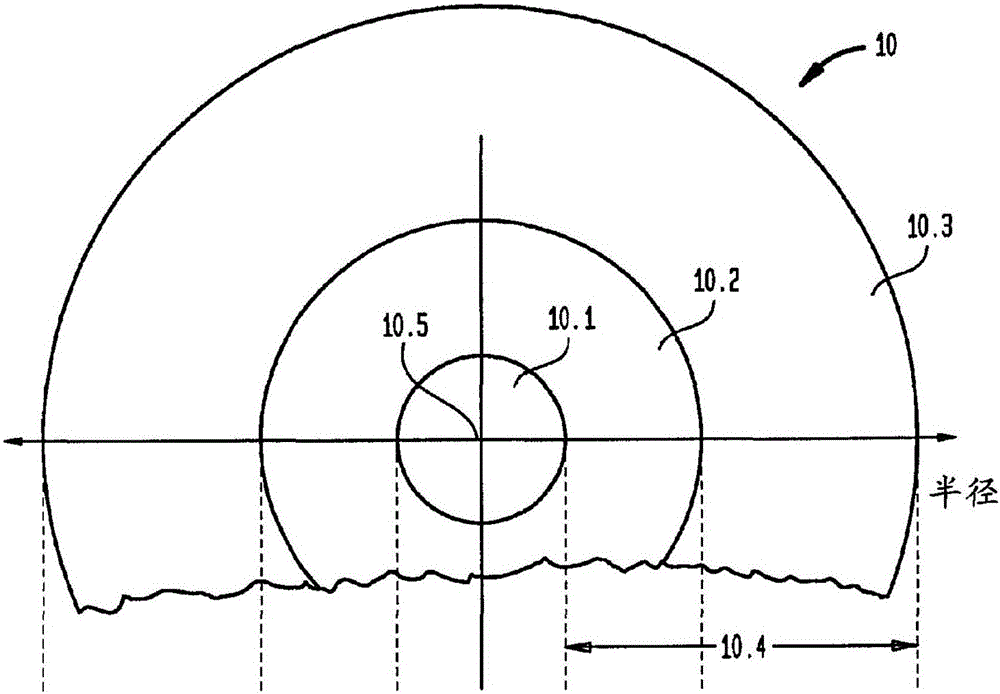

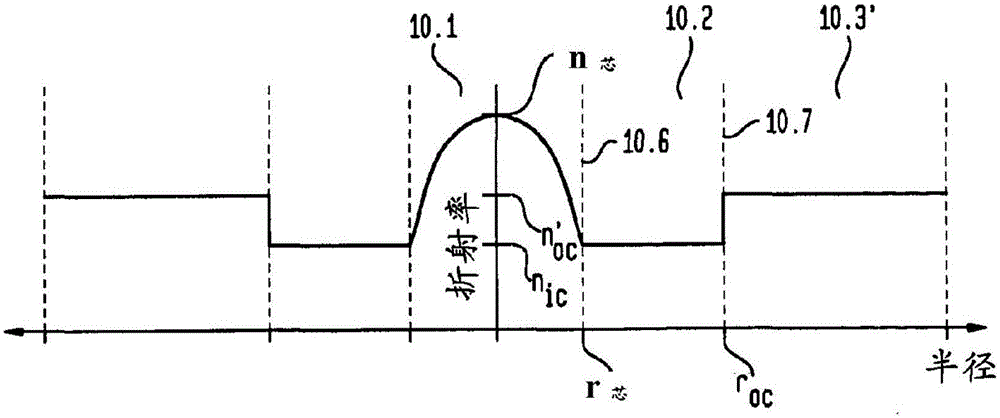

Design and manufacture of multi-mode optical fibers

A technology of multimode optical fiber and optical fiber, applied in cladding optical fiber, graded index core/cladding optical fiber, optics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Glossary

[0046] Bending: Macrobending (often referred to simply as bending) occurs when an optical fiber is bent, coiled, or crimped such that its curvature is relatively constant along at least a portion of its length. In contrast, microbending occurs when the curvature changes significantly over an adiabatic length scale for a particular fiber (eg, along the length of the fiber on sub-millimeter scales). Such microbends are formed, for example, by pressing the fiber against sandpaper in a standard microbend test.

[0047] Intermediate Wavelength: References to wavelengths in this discussion are intended to refer to wavelengths representing the intermediate wavelengths of particular light emissions, with the understanding that all such emissions are characterized by known ranges including wavelengths above and below the intermediate wavelength line width.

[0048] Glass Fiber: The type of fiber described here is essentially made of glass (e.g., silica) in which the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com