Cable for flexible robot and manufacturing method

A robot and cable technology, applied in cable/conductor manufacturing, power cables, insulated cables, etc., can solve the problems of poor wear resistance of PVC, reduced cable induction ability, weakened cable transportation performance, etc., to achieve flexibility Strengthen and improve the service life, the effect of convenient installation and laying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing.

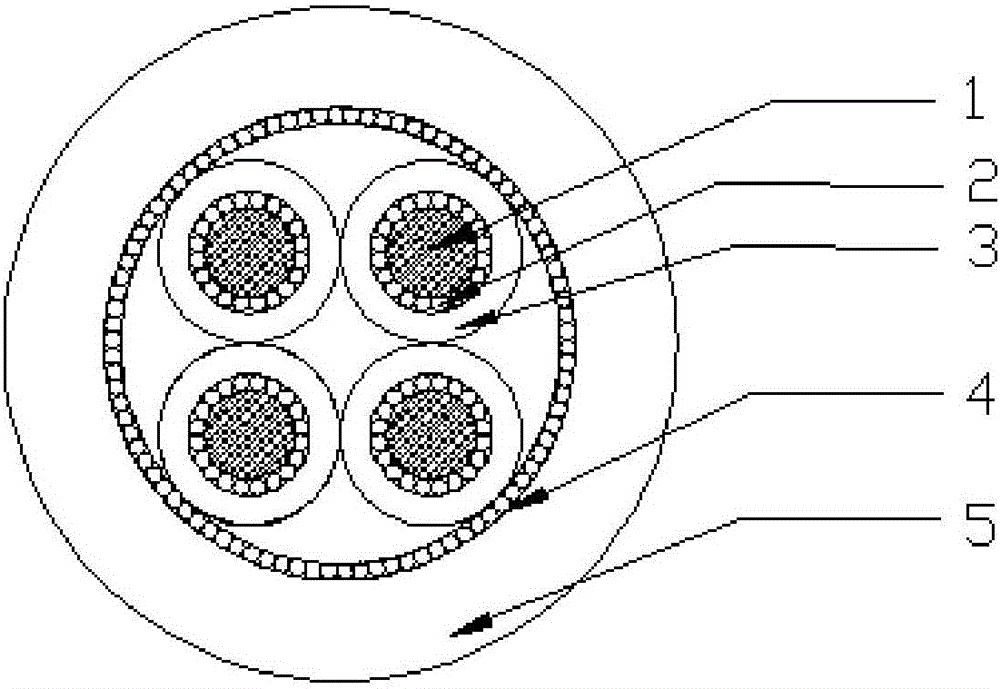

[0027] see figure 1 , figure 2 with image 3 , one of the flexible robot cables of the present invention includes multi-strand conductors, multiple polyvinyl chloride insulating layers 3 , copper wire shielding layer 4 and PUR sheath 5 .

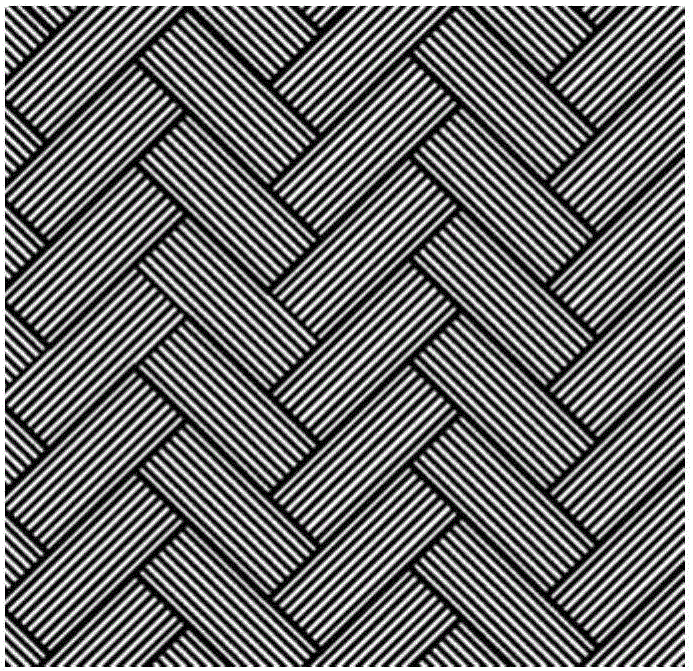

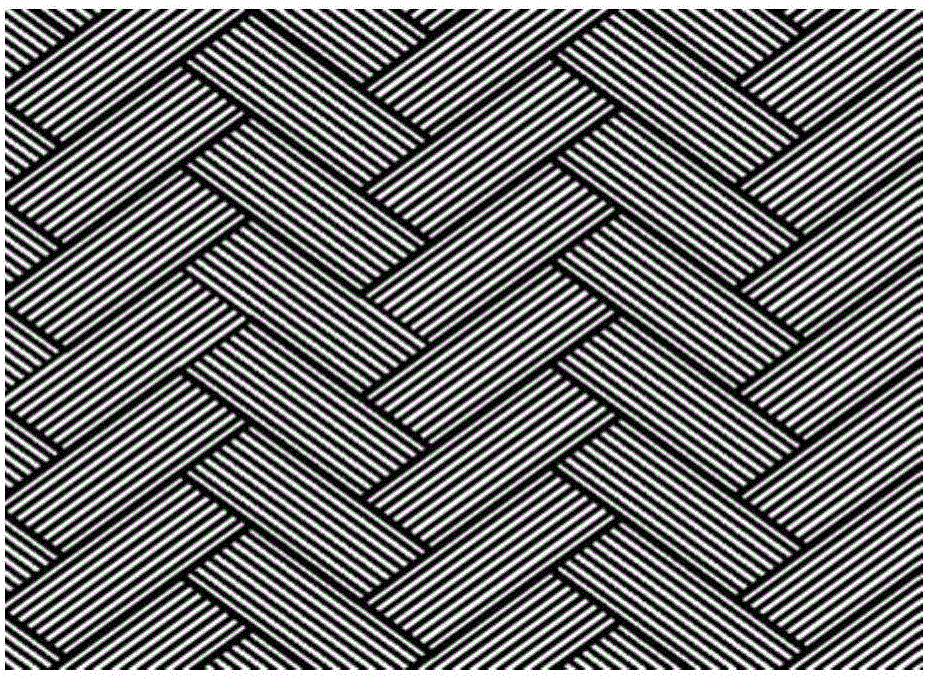

[0028] Because the present invention is applied in the ultra-super flexible robot, so need to adopt the conductor of soft structure weaving, simultaneously for the convenience of weaving and increase its bending resistance and load-bearing capacity, each conductor is made of polyparaphenylene terephthalamide fiber 1 and A plurality of oxygen-free copper wires 2 placed on the outer layer of the poly-p-phenylene terephthalamide fiber 1 are braided with a braiding density greater than 90% through a braiding machine. This structure can effectively improve the stretchability, tensile strength, flexibility and electrical signal transmission...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com