General method for machining complex curved surface of non-spherical cutter in multi-axis-linkage CNC manner

A technology of complex surfaces and general methods, which is applied in the field of multi-axis linkage CNC machining of complex surfaces with aspherical tools, and can solve the problems of complex surface planning, precision control and interference checking of aspherical tools, and no optimization theory for tool motion control is formed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be further described below in conjunction with accompanying drawing:

[0055] The present invention comprises the following steps:

[0056] (1) Design the generating motion of the tool relative to the surface of the workpiece:

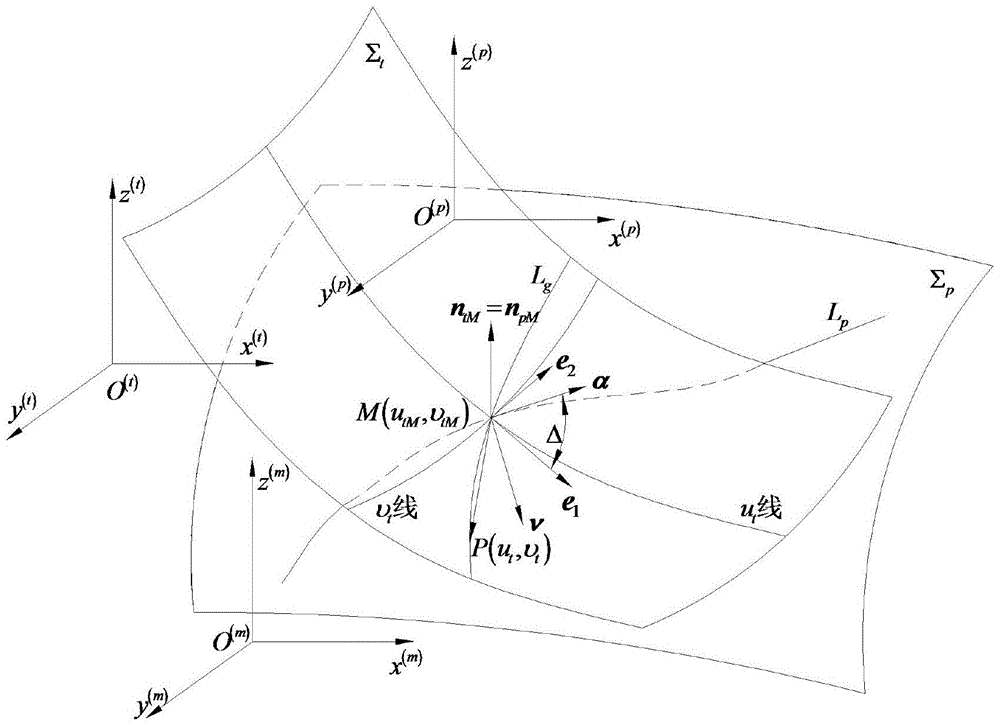

[0057] (1) Use the tool surface with a vector function Σ with continuous third-order partial derivatives t :r t = r t (u t ,υ t ) description, where u t ,υ t Form an orthogonal parameter network, and use the vector function Σ with continuous third-order partial derivatives to process the surface p :r p = r p (u p ,υ p ) description, where u p ,υ p Form an orthogonal parameter network. The tool contact trajectory curve L on the surface to be machined p Use the vector function r pM = r pM (u pM (sp ), υ pM (s p )) description, where, s p for the curve L p The arc length parameter;

[0058] (2) Surface active frame passing through the tool surface;

[0059] S ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com