Pin-type lifting device control system of ocean engineering platform

A marine engineering and control system technology, applied in the general control system, control/regulation system, program control, etc., can solve problems such as limited space for pile fixing barrels, hidden dangers of platform safety, and inability to guarantee the safety of marine engineering platforms, etc., to reduce Maintenance cost and safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

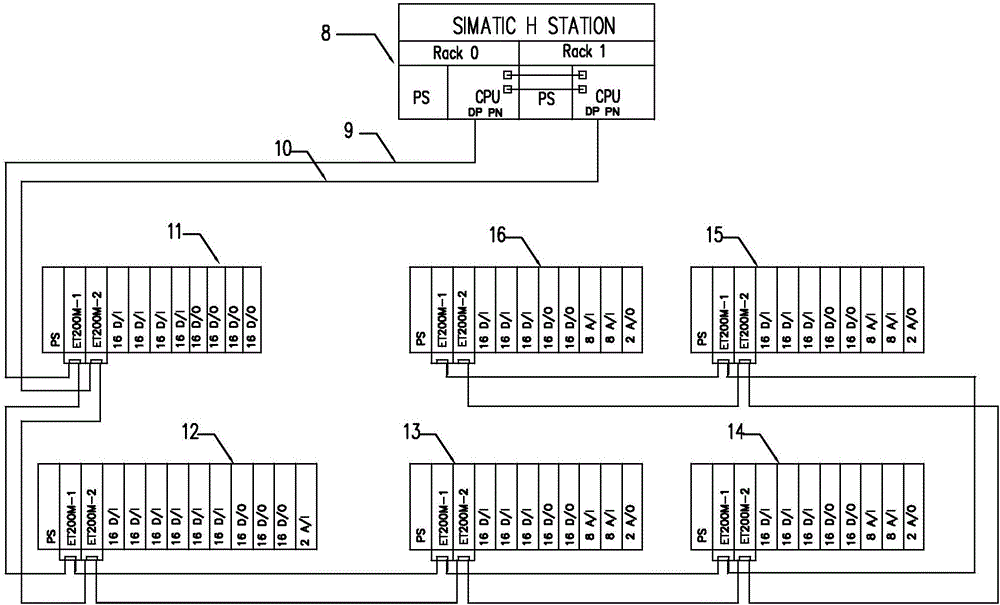

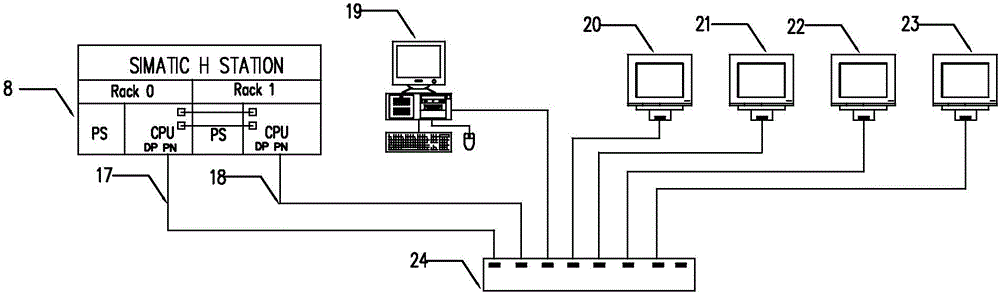

[0029] The present invention will be further described below in conjunction with the accompanying drawings. Such as Figure 1-4As shown, a plug-type lifting device control system for an offshore engineering platform includes a central console, a redundant PLC controller 8, a hydraulic pump station control unit, a control unit next to the pile leg machine, a pile leg operation state detection device, and CCTV monitoring device.

[0030] The central console includes buttons, indicator lights, CMS monitoring device and remote I / O module; the remote I / O module collects the control instructions sent by the staff through the button, and after being processed by the PLC controller, the remote I / O module Output the status information to the indicator light, and transmit the status information of the control system to the CMS monitoring device through the PROFINET network for display and filing.

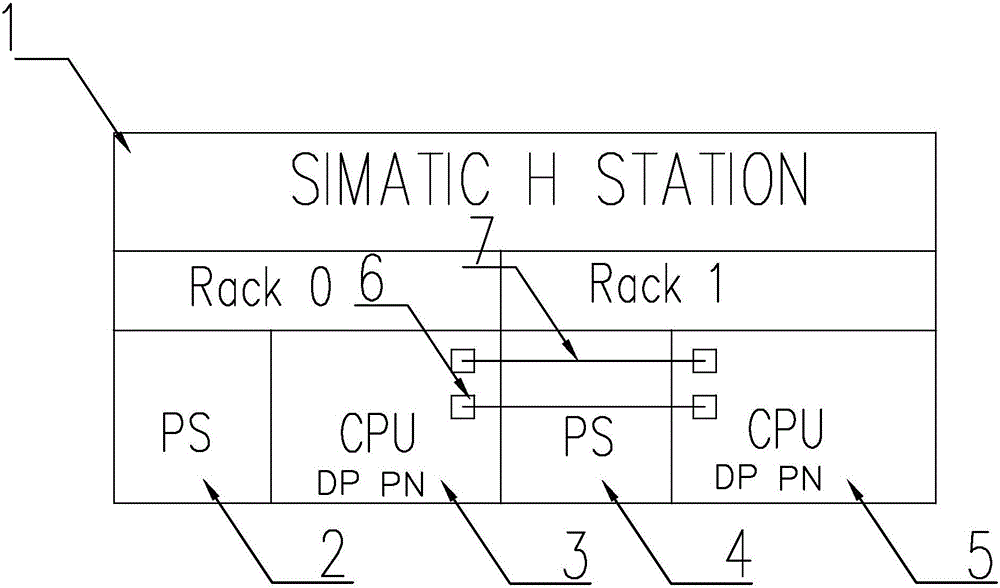

[0031] Described redundant PLC controller 8 comprises active backplane bus 1, power sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com