Air magnetizing energy-saving emission-reducing device for engine inlet air

An air magnetization, energy-saving and emission-reducing technology, which is applied in the direction of engine components, combustion engines, machines/engines, etc., can solve the problems of weak air magnetization ability and unsatisfactory fuel energy-saving and emission-reduction effects, so as to achieve the optimization of magnetization effect, fuel saving and emission reduction. The effect of row protrusion and magnetization enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

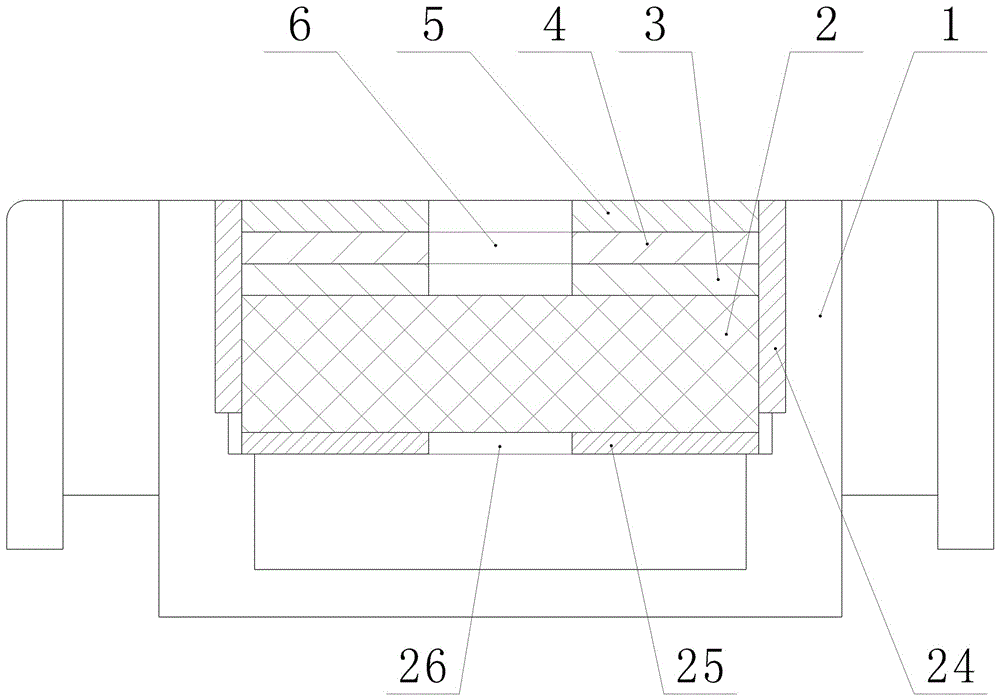

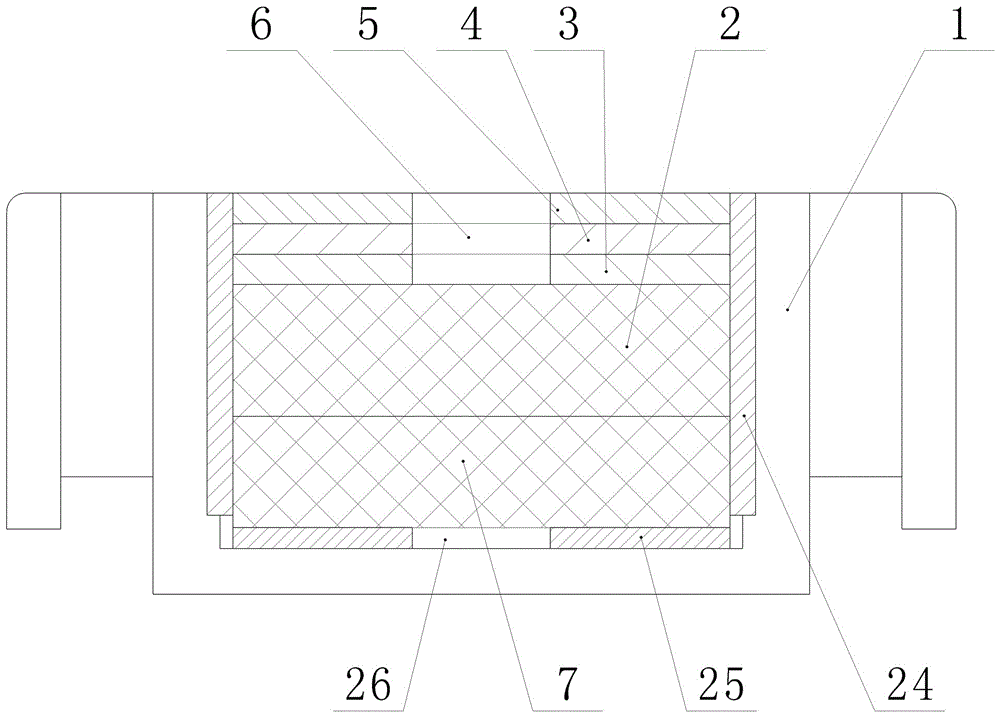

[0041] refer to figure 1 , an engine intake air magnetization energy saving and emission reduction device, comprising a magnetizer arranged in a housing 1, the magnetizer includes

[0042] the first permanent magnet 2;

[0043] The first magnetically conductive metal sheet 3, the second magnetically conductive metal sheet 4 and the nonmagnetically conductive material sheet 5, the first magnetically conductive metal sheet 3, the second magnetically conductive metal sheet 4 and the nonmagnetically conductive material sheet 5 are sequentially stacked , the middle part of the first magnetically conductive metal sheet 3, the second magnetically conductive metal sheet 4 and the non-magnetically conductive material sheet 5 is provided with a first cavity 6;

[0044] A shielding sleeve 24 and a shielding layer 25, the middle part of the shielding layer 25 is provided with a shielding layer through hole 26;

[0045] One end surface of the first magnetically conductive metal sheet 3 ...

Embodiment 2

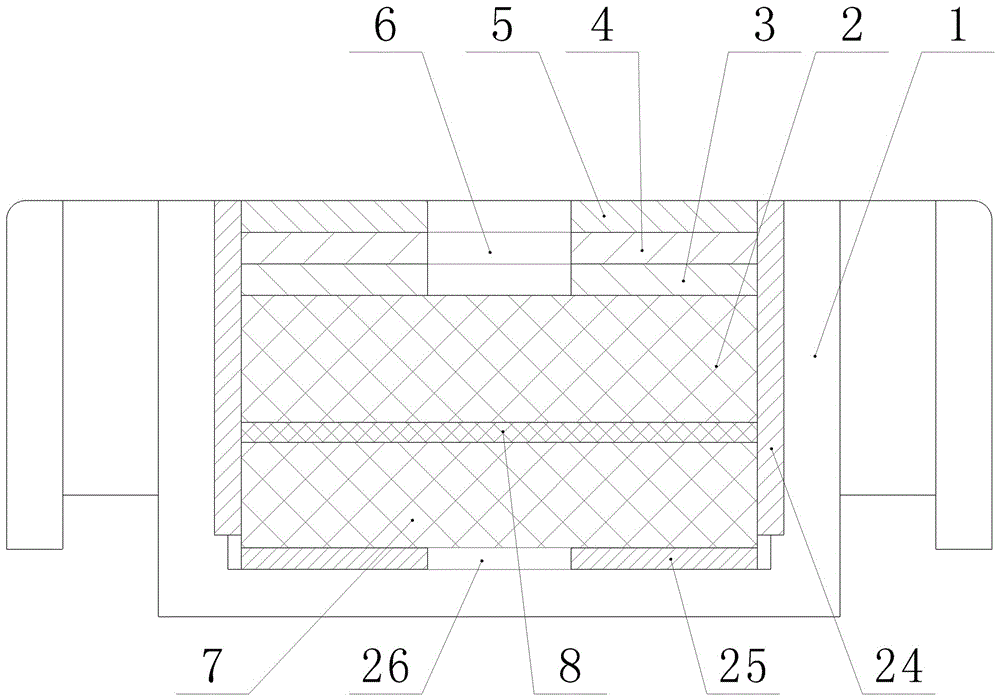

[0054] refer to Figure 5 , an engine intake air magnetization energy saving and emission reduction device, comprising a magnetizer arranged in a housing 1, the magnetizer includes

[0055] the first permanent magnet 2;

[0056]The first magnetically conductive metal sheet 3, the second magnetically conductive metal sheet 4 and the nonmagnetically conductive material sheet 5, the first magnetically conductive metal sheet 3, the second magnetically conductive metal sheet 4 and the nonmagnetically conductive material sheet 5 are sequentially stacked , the middle part of the first magnetically conductive metal sheet 3, the second magnetically conductive metal sheet 4 and the non-magnetically conductive material sheet 5 is provided with a first cavity 6;

[0057] A shielding sleeve 24 and a shielding layer 25, the middle part of the shielding layer 25 is provided with a shielding layer through hole 26;

[0058] One end surface of the first magnetically conductive metal sheet 3 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com