In-tunnel prefabricated cable tube and prefabricated water drainage pipe structure

A technology for cable pipes and drainage pipes, which is applied in the field of new cable passing through tunnels and drainage structures in tunnels. It can solve problems such as waste of investment, easy damage to the ditch body, and difficulty in setting up molds, so as to speed up the construction progress, reduce the tunnel section, Conducive to antifreeze effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with specific embodiments.

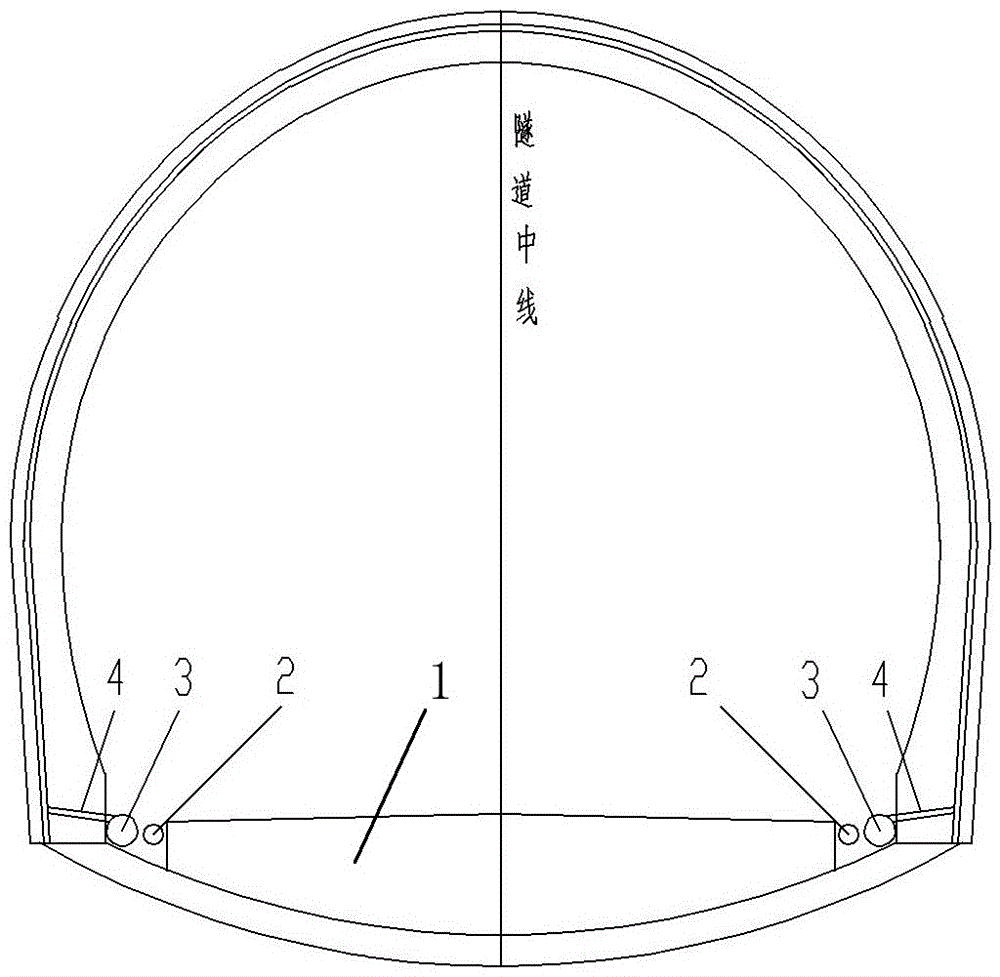

[0020] The present invention relates to a prefabricated cable tube and a prefabricated drainage tube structure in a tunnel. The prefabricated cable tube 2 and the prefabricated drainage tube 3 are laterally arranged side by side on the inner side of the tunnel lining arch foot and the outer side of the invert filling 1. A gap is provided between the lateral end of the invert filler 1 and the arch foot of the tunnel lining, and the prefabricated cable pipe 2 and the prefabricated drainage pipe 3 are located in the gap. The pipe diameter of the prefabricated drain pipe 3 is larger than the prefabricated cable pipe 2, and the prefabricated drain pipe 3 is located outside the prefabricated cable pipe 2. The diameter of the prefabricated drainage pipe 3 can be flexibly adjusted according to the water output, and the diameter of the prefabricated cable pipe 2 can be flexibly adjus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com