Motor-driven extrusion-type underground annular blowout preventer and communication method thereof

A motor-driven, extrusion-type technology, applied in the field of blowout prevention technology, can solve problems such as danger and weak automation, and achieve the effects of preventing well kick and blowout, reducing total cost and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

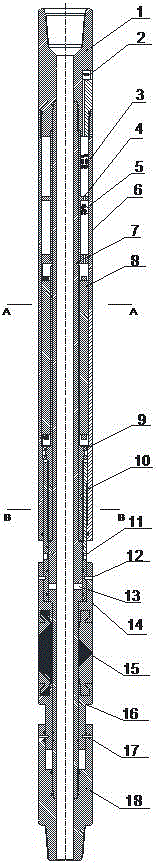

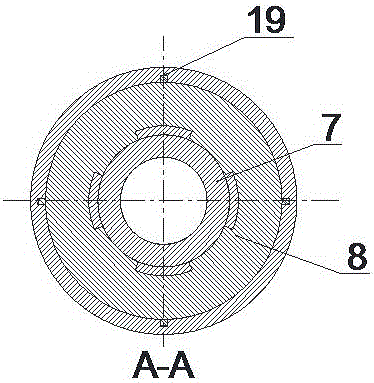

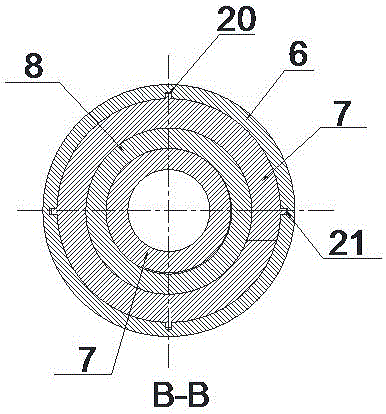

[0031] like figure 1 As shown, a motor-driven extrusion type downhole annular blowout preventer includes an upper joint (1), a fixed sleeve (4), an outer sleeve (6), a central sleeve (7), a motor (8), a compression cylinder (10), rubber cylinder upper joint (8), rubber cylinder (15), rubber cylinder lower joint (10) and lower joint (18), the fixed cylinder (4), motor (8), compression cylinder (10 ) and the rubber cylinder (15) are overlaid on the central cylinder (7); the central cylinder (7) is threadedly connected with the upper joint (1) and the lower joint (18) respectively, and the compression cylinder (10) is driven by the motor (8) The rubber cylinder (15) can be compressed by the compression cylinder (10) to achieve sealing and blowout prevention, and the rubber cylinder (15) can be dragged in reverse to realize unsealing, and the rubber cylinder (15) is compressed and sealed while the cycle of the compression cylinder (10) The hole (11) is aligned with the circulatio...

specific Embodiment 2

[0032] Based on the device of embodiment 1, the blowout prevention method of the motor-driven extrusion type downhole annular blowout preventer is:

[0033] 1. When an overflow is found, the formation high-pressure fluid enters the drill string through the drill bit and flows upward. When the overflow is found, after the well is shut down on the ground, the formation high-pressure liquid enters the drill string through the drill bit and flows upward, so that the downhole blowout prevention tools near the drill bit are closed. , to block the passage in the drill string. At the same time, formation high-pressure fluid in the wellbore annulus passes through the lower joint of the downhole blowout preventer, and blowout prevention measures need to be taken at this time.

[0034] 2. The radio transmitter (a-2) of the ground control center (a) transmits the control command to the wellhead acoustic wave communication subsection (b), through the electro-acoustic transducer (b) in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com