Shear wall template support

A shear wall and formwork technology, which is applied in the direction of formwork/formwork/work frame, formwork/formwork/work frame connection, construction components on-site preparation, etc., can solve the problem of wall distortion, inconvenient formwork positioning and Fixing, poor pouring quality and other problems, to achieve the effect of convenient installation and disassembly, simple and reasonable structure, and convenient processing and manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

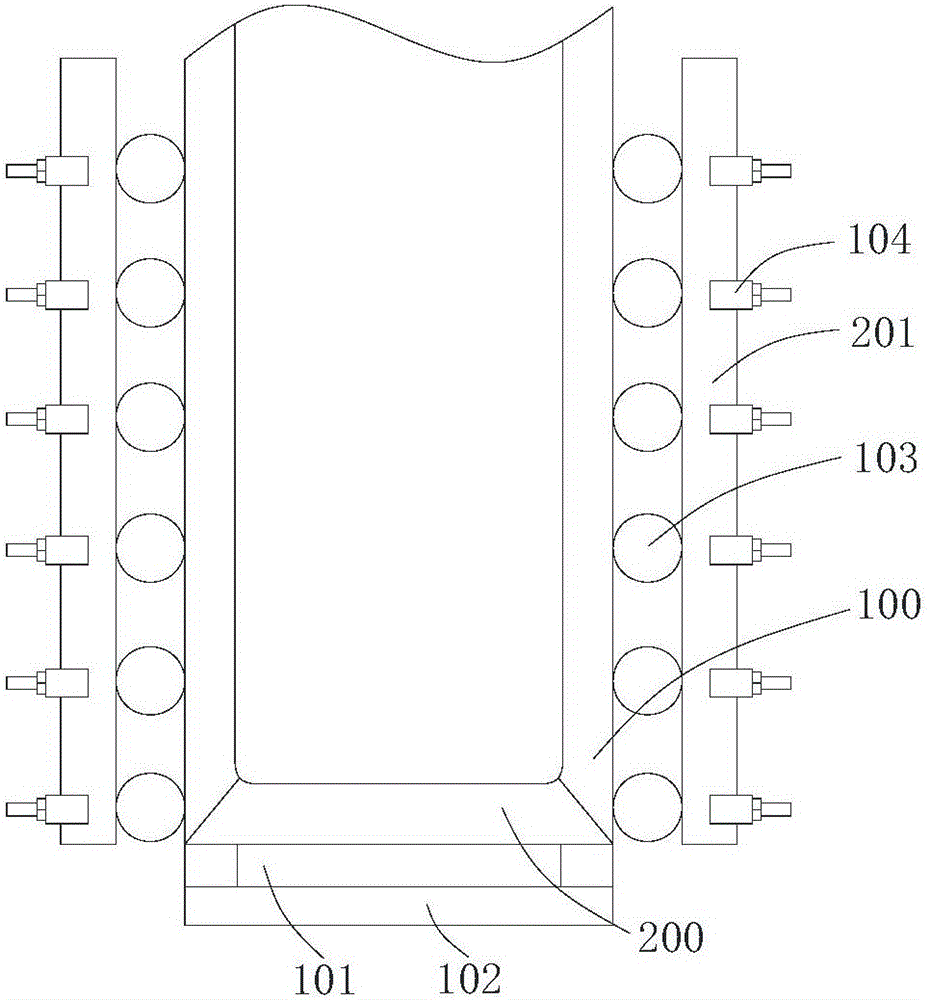

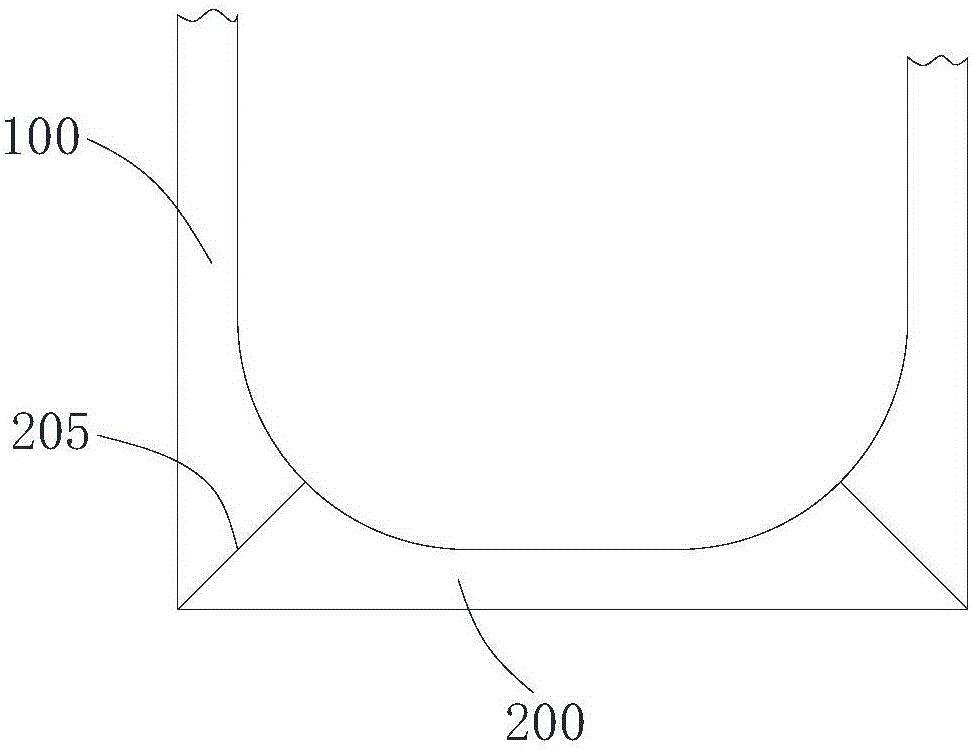

[0041] Please refer to Figure 1-7 , this embodiment provides a shear wall formwork support, which is used for the formwork erection at the end of the shear wall, including a reinforcement assembly 300, a support assembly 400, a connection assembly 500, two side formwork 100 arranged oppositely, and two The end formwork 200 between the side formworks 100, when actually erected, the side formwork 100 and the end formwork 200 are erected on the floor or the foundation plane, and the side formwork 100 and the end formwork 200 are spliced to form a pouring cavity, which is opposite to the end formwork 200 One end of the wall is connected with the poured wall or other cavities to be poured. When pouring, the formwork bears the impact force of the concrete. After the pouring is completed, the formwork can be removed after the concrete solidifies to meet the strength requirements. Traditional formwork support, when pouring, misalignment is prone to occur at the contact corner of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com