Single-layer space lattice structure assembled double-ring node

A spatial grid and prefabricated technology, applied in building construction, construction, etc., can solve the problems of material waste and achieve the effects of high prefabrication, fast construction speed, and light structural modeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

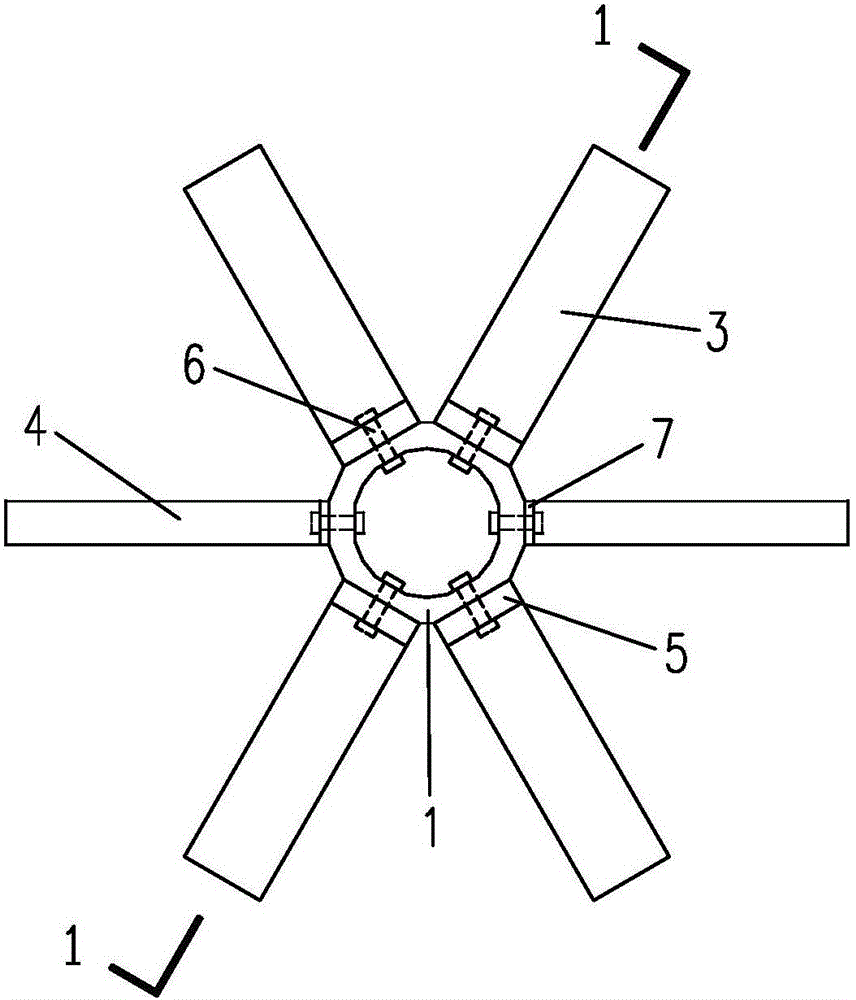

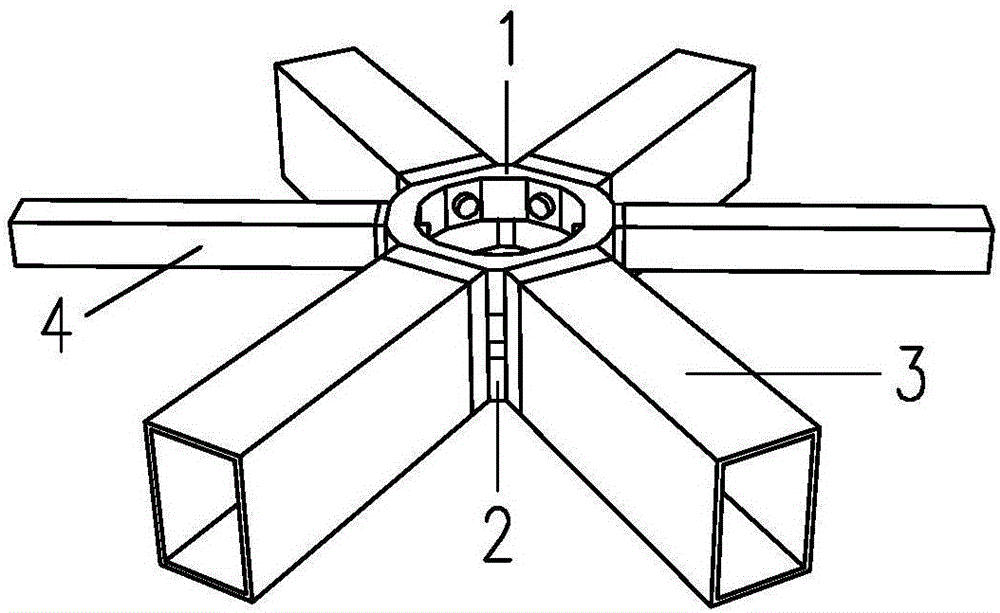

[0037] Figure 1 to Figure 6 It is a schematic diagram of nodes in Embodiment 1 of the present invention, and it is a node in a single-layer spatial grid structure that distinguishes primary stress-bearing members and secondary stress-bearing members. combine figure 1 , figure 2 and image 3 , the present invention mainly includes five parts: one is the central node ring, which is divided into an upper node ring 1 and a lower node ring 2, which are cut and processed from a solid ring, and the ring is provided with bolt holes, which can be connected with the main rods 3 and The secondary rods 4 are connected; one is the sealing plate connector 5, which has bolt holes on the upper and lower flanges; the other is the small sealing plate 7, which is a rectangular steel plate with bolt holes, and one side is welded to the secondary rod 4 One side of the rod end is connected to the upper node ring through high-strength bolts 6; the other is the high-strength bolt 6, which connec...

Embodiment 2

[0043] Figure 7 to Figure 10 It is a schematic diagram of Embodiment 2 of the present invention. When the stress on each member of the single-layer space grid structure is relatively uniform, all the members connected by the central node ring are the main member 3, and other members and connection methods are the same as in the first embodiment.

[0044] The processing and assembly process of the present invention are described below:

[0045] 1. According to the specific situation of the project, design the single-layer spatial grid structure, determine the stress situation of the nodes, determine the node form as Embodiment 1 or Embodiment 2 and the specifications of the rods;

[0046] 2. According to the data in the first step, further calculate the size of the central node ring, the sealing plate connector and the high-strength bolt, and determine the performance grade of the high-strength bolt and the grade of the steel. Wherein, the height of the connecting piece of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com