A kind of preparation method of superhydrophobic recycled paper

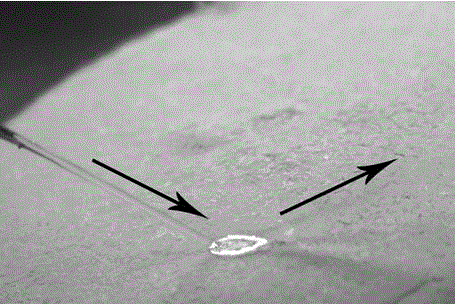

A super-hydrophobic and recycled paper technology, applied in papermaking, paper recycling, waste paper processing, etc., can solve the problems of papermaking industry pollution and energy consumption, unusable packaging and storage, paper loss of use value, etc., to achieve good internal and external consistency, Good water repellency and good writing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

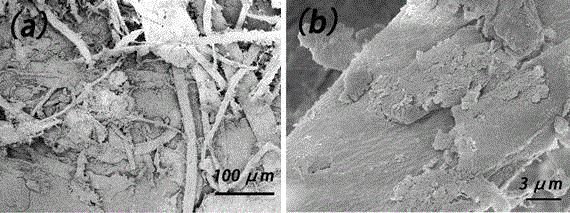

[0035] (1) Preparation of inorganic superhydrophobic filler: solution A: ethyl orthosilicate was added to methanol (V:V=1:2), and stirred for 5 minutes. Solution B: add ammonia water 0.02 (M) to methanol (V:V=15:20). Mix solution A and solution B (V:V=30:35). The pH of the mixture was adjusted to 5 with hydrochloric acid (0.1 M). 0.02 M ammonia water was added dropwise to the system to adjust the pH to 9, and aged for 10 hours to obtain a white opaque gel. The obtained gel was transferred to a reaction kettle, n-hexane and hexamethyldisilazane modifier were added, the volume ratio of the three was 12:20:3, and then reacted at 80°C for 10 h. Then suction filter and wash with n-propanol to obtain superhydrophobic silica gel. The obtained gel was dried at 60 °C for 6 h to remove the solvent and residual reactants, and then ground to obtain the inorganic superhydrophobic filler.

[0036] (2) Preparation of polydopamine-cellulose: The waste paper fragments were immersed in deio...

Embodiment 2

[0039] (1) Preparation of inorganic superhydrophobic filler: solution A: add ethyl orthosilicate to methanol (V:V=1:2), and stir for 10 minutes. Solution B: add ammonia water 0.02 (M) to methanol (V:V=15:20). Mix solution A and solution B (V:V=30:35). The pH of the mixture was adjusted to 5 with hydrochloric acid (0.1 M). 0.02 M ammonia water was added dropwise to the system to adjust the pH to 9, and aged for 12 hours to obtain a white opaque gel. The obtained gel was transferred to a reaction kettle, n-hexane and hexamethyldisilazane modifier were added, the volume ratio of the three was 12:20:3, and then placed at 80°C for 14 h. Then suction filter and wash with n-propanol to obtain superhydrophobic silica gel. The obtained gel was dried at 60 °C for 6 h to remove the solvent and residual reactants, and then ground to obtain the inorganic superhydrophobic filler.

[0040] (2) Preparation of polydopamine-cellulose: The waste paper fragments were immersed in deionized wat...

Embodiment 3

[0043](1) Preparation of inorganic superhydrophobic filler: solution A: add ethyl orthosilicate to methanol (V:V=1:2), and stir for 5 minutes. Solution B: add ammonia water 0.02 (M) to methanol (V:V=15:20). Mix solution A and solution B (V:V=30:35). The pH of the mixture was adjusted to 5 with hydrochloric acid (0.1 M). 0.02 M ammonia water was added dropwise to the system to adjust the pH to 9, and aged for 11 hours to obtain a white opaque gel. The obtained gel was transferred to a reaction kettle, n-hexane and hexamethyldisilazane modifier were added, the volume ratio of the three was 12:20:3, and then placed at 80°C for 12 h. Then suction filter and wash with n-propanol to obtain superhydrophobic silica gel. The obtained gel was dried at 60 °C for 8 h to remove the solvent and residual reactants, and then ground to obtain the inorganic superhydrophobic filler.

[0044] (2) Preparation of polydopamine-cellulose: The waste paper fragments were immersed in deionized water...

PUM

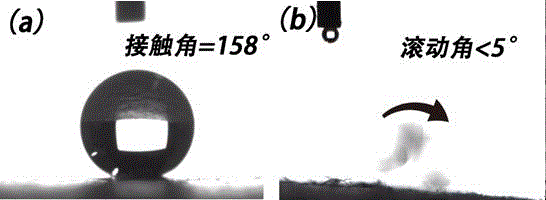

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com