Method for isomerization of light hydrocarbon

A technology of isomerization and light hydrocarbons, which is applied in the field of isomerization of light hydrocarbons, can solve the problem of octane number limitation of isomerized gasoline products, and achieve the effect of increasing octane number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

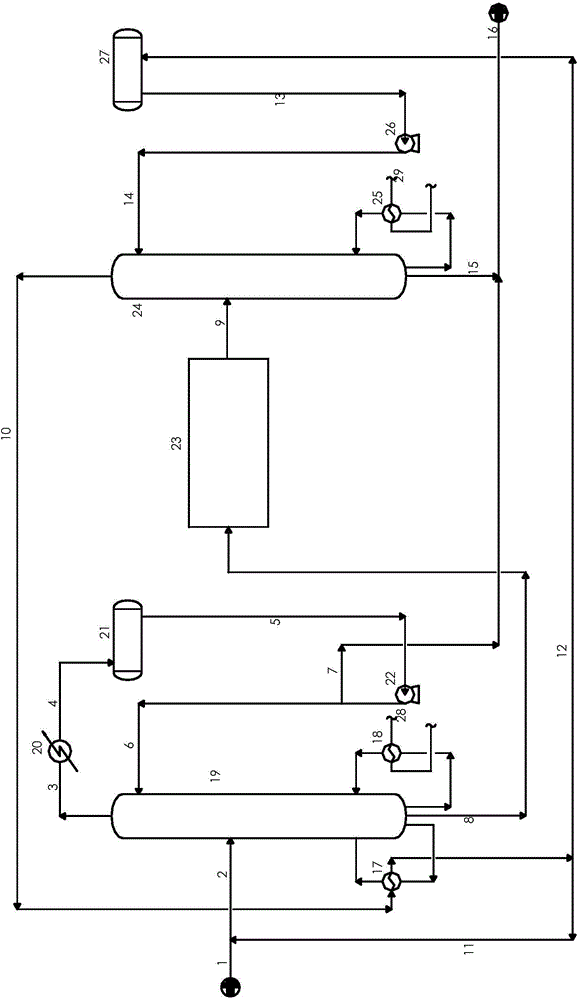

[0031] In this embodiment, the attached figure 1 In the process scheme shown, the processing scale of the isomerization unit is 300,000 tons / year. The light hydrocarbon raw material is the light hydrocarbon through hydrotreating, besides C5 and C6 alkanes, it also contains a small amount of other components, its specific composition data is shown in Table 1, it can be seen from Table 1: the C5 alkanes in the raw material The molar content is 59.02%, wherein isopentane accounts for 44.92% of the C5 paraffin content. The research octane number of the raw material was 72.4. The composition and properties of the isomerized gasoline product are also listed in Table 1, as can be seen from Table 1: the isopentane in the isomerized gasoline product accounts for 87.58% of the C5 paraffin content, and the research method octane number of the product increases to 85.5.

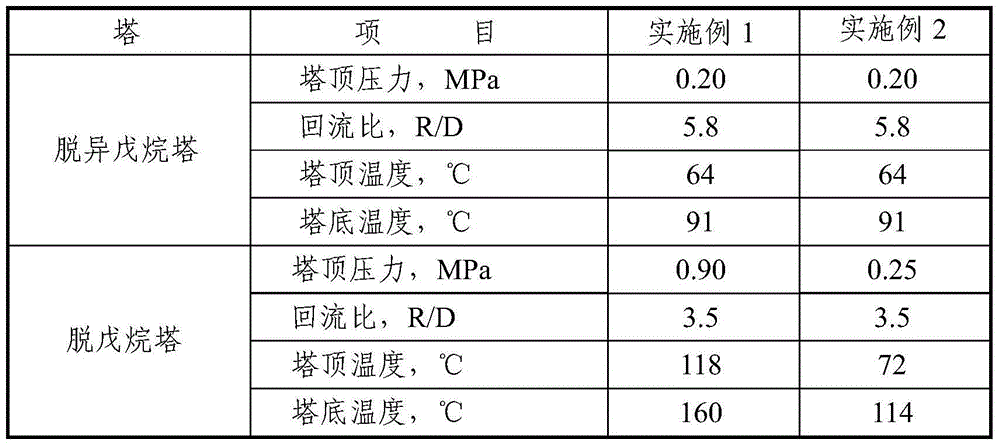

[0032] Table 2 lists the operating conditions of the depentanizer and the depentanizer. The pressure at the top of...

Embodiment 2

[0035] Example 2 adopts the process scheme in Example 1, except that the gas phase stream drawn from the top of the depentanizer adopts a conventional condensation cooling method.

[0036] The light hydrocarbon raw material of Example 2 is the same as that of Example 1, the process conditions of the isomerization reaction part of the two are also the same, and the separation precision of the de-isopentanizer and the depentanizer is also the same.

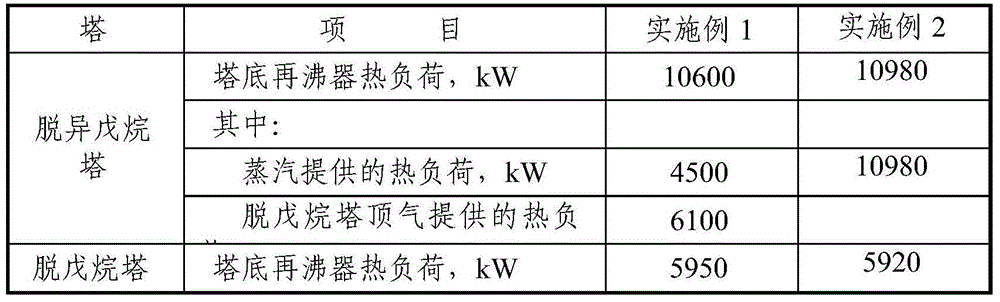

[0037] The operating conditions of the de-isopentanizer and the depentanizer in Example 2 are shown in Table 2, and the heat loads of the reboilers of the two towers are shown in Table 3.

[0038] In this embodiment, the total heat load provided by the external heat source for the deisopentanizer and the depentanizer is 16900 kW, which is 61.72% higher than the total heat load provided by the external heat source in Example 1 of 10450 kW.

[0039] Table 1

[0040]

Light hydrocarbon feedstock

Isomerized gasoline ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Heat load | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com