Superhydrophobic coating, anti-pollution-flashover superhydrophobic insulator and preparation technique thereof

A technology of super-hydrophobic coating and super-hydrophobic coating, which is applied in the direction of coatings, insulators, electrical components, etc., can solve the problems of insulators such as reduced pollution flashover resistance, hydrophobicity, and aging degradation, and achieves improved pollution flashover resistance. Long service life and high aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

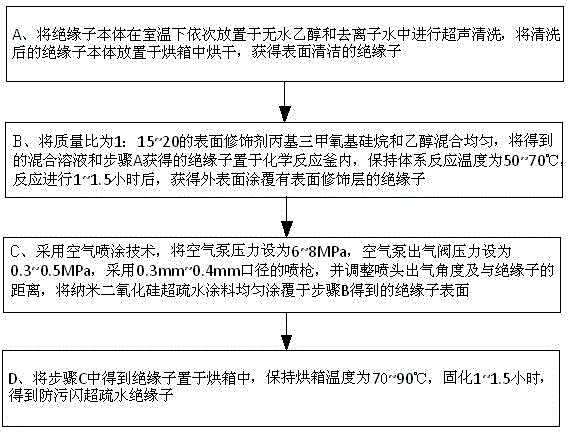

Image

Examples

Embodiment 1

[0025] The superhydrophobic coating for anti-pollution flashover insulators described in this embodiment includes a surface modification layer disposed on the outer surface of the insulator and a superhydrophobic coating disposed on the surface modification layer. The surface modification layer is made of surface modification liquid, the surface modification liquid is composed of surface modifier propyltrimethoxysilane and ethanol with a mass ratio of 1:20, and the superhydrophobic coating is made of nano silicon dioxide superhydrophobic coating. Among them, the nano-silica superhydrophobic coating is a prior art, and it does not have the problem of insufficient disclosure in this patent.

[0026] The anti-pollution flashover superhydrophobic insulator described in this embodiment includes an insulator body made of glass and the above-mentioned superhydrophobic coating, and the superhydrophobic coating is evenly coated on the outer surface of the insulator body.

[0027] Such ...

Embodiment 2

[0034] The superhydrophobic coating for anti-pollution flashover insulators described in this embodiment includes a surface modification layer disposed on the outer surface of the insulator and a superhydrophobic coating disposed on the surface modification layer. The surface modification layer is made of surface modification liquid, the surface modification liquid is composed of surface modifier propyltrimethoxysilane and ethanol with a mass ratio of 1:15, and the superhydrophobic coating is made of nano silicon dioxide superhydrophobic coating.

[0035] The anti-pollution flashover super-hydrophobic insulator described in this embodiment includes a ceramic insulator body and the above-mentioned super-hydrophobic coating, and the super-hydrophobic coating is evenly coated on the outer surface of the insulator body.

[0036] Such as figure 1 As shown, the preparation process of the anti-pollution flashover superhydrophobic insulator in this embodiment includes the following st...

Embodiment 3

[0042] The superhydrophobic coating for anti-pollution flashover insulators described in this embodiment includes a surface modification layer disposed on the outer surface of the insulator and a superhydrophobic coating disposed on the surface modification layer. The surface modification layer is made of surface modification liquid, the surface modification liquid is composed of surface modifier propyltrimethoxysilane and ethanol with a mass ratio of 1:18, and the superhydrophobic coating is made of nano silicon dioxide superhydrophobic coating.

[0043] The anti-pollution flashover superhydrophobic insulator described in this embodiment includes an insulator body made of glass and the above-mentioned superhydrophobic coating, and the superhydrophobic coating is evenly coated on the outer surface of the insulator body.

[0044] Such as figure 1 As shown, the preparation process of the anti-pollution flashover superhydrophobic insulator in this embodiment includes the followin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com