Silicon rubber and negative oxygen ion powder blending closed-cell foaming material and preparation method thereof

A technology of negative oxygen ion powder and foaming material, applied in the field of foaming materials, can solve the problems of inability to fully utilize the negative oxygen ion powder of air energy, poor dispersibility, affecting quality and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] A preparation method of a silicone rubber and negative oxygen ion powder blended closed-cell foaming material, comprising the steps of:

[0057] (1) Preparation of negative oxygen ion premixed powder: 100PHR tourmaline powder, 100PHR wizard R series plastic / rubber additive 1250 mesh, 5PHR chelating titanate coupling agent, 20PHR white carbon black, 20PHR Light calcium carbonate is put into a Φ800*1000mm high-speed mixing tank, and stirred for 12 minutes. During the stirring process, the temperature is continuously controlled at 80°C. After the stirring is completed, the negative oxygen ion premixed powder is obtained, and the negative oxygen ion premixed powder is prepared according to the weight of the formula. Proportion weighing and packaging;

[0058] (2) Internal mixer mixing: first put 100PHR of modified silicone rubber into a pressurized internal mixer and knead for 4 to 6 minutes, then add 25PHR of negative oxygen ion premixed powder and 4PHR of structure regula...

Embodiment 2

[0076] The preparation method of the blended closed-cell foam material of silicone rubber and negative oxygen ion powder described in Example 2 is completely consistent with Example 1, the difference being that the weight ratio of the raw materials used in Example 2 is as follows:

[0077] Modified silicone rubber 100PHR

[0078] Negative oxygen ion premixed powder 35PHR;

[0079] Structural regulator 6PHR

[0081] Activator 1.2PHR

[0082] Cross-linking agent 0.5PHR

[0083] Auxiliary cross-linking agent 0.4PHR

[0084] Blowing agent 6PHR

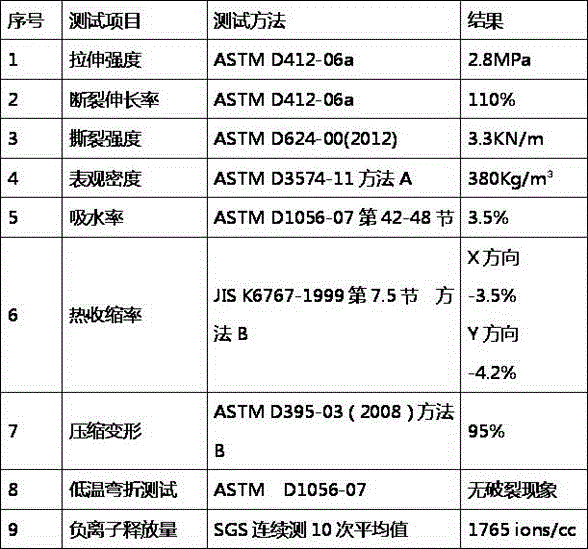

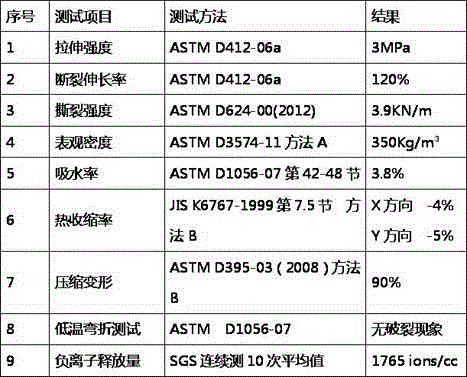

[0085] The physical properties of the silicone rubber and negative oxygen ion powder blended closed-cell foam material prepared in Example 2 are shown in Table 3 below:

[0086]

[0087] Table 3, embodiment 2 physical properties table

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com