A five-axis double swing head gantry milling machine simulating cutting force loading device and using method

A technology of gantry milling machine and loading device, which is applied in the direction of metal processing equipment, metal processing machine parts, measuring/indicating equipment, etc., which can solve the problems of high manufacturing cost of machine tools, expensive processing tools, large consumption of materials and processing tools, etc. To achieve the effect of reducing the cost of testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

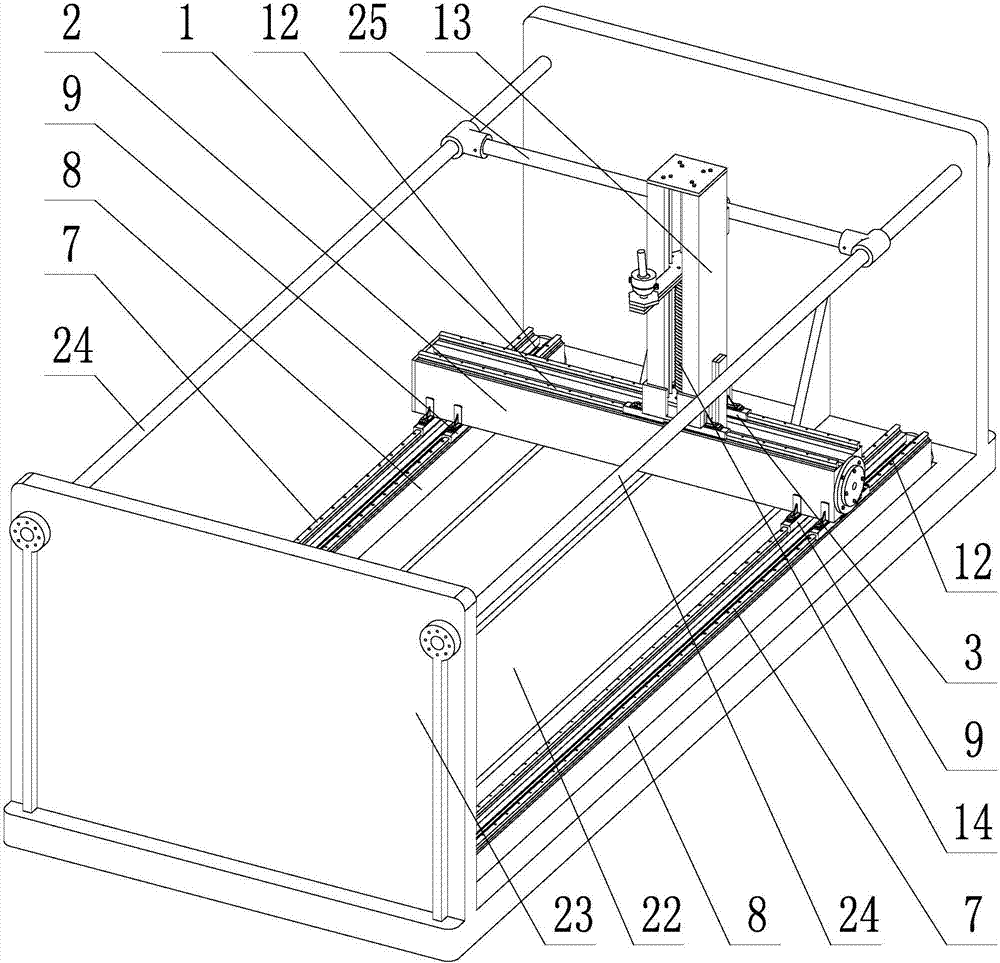

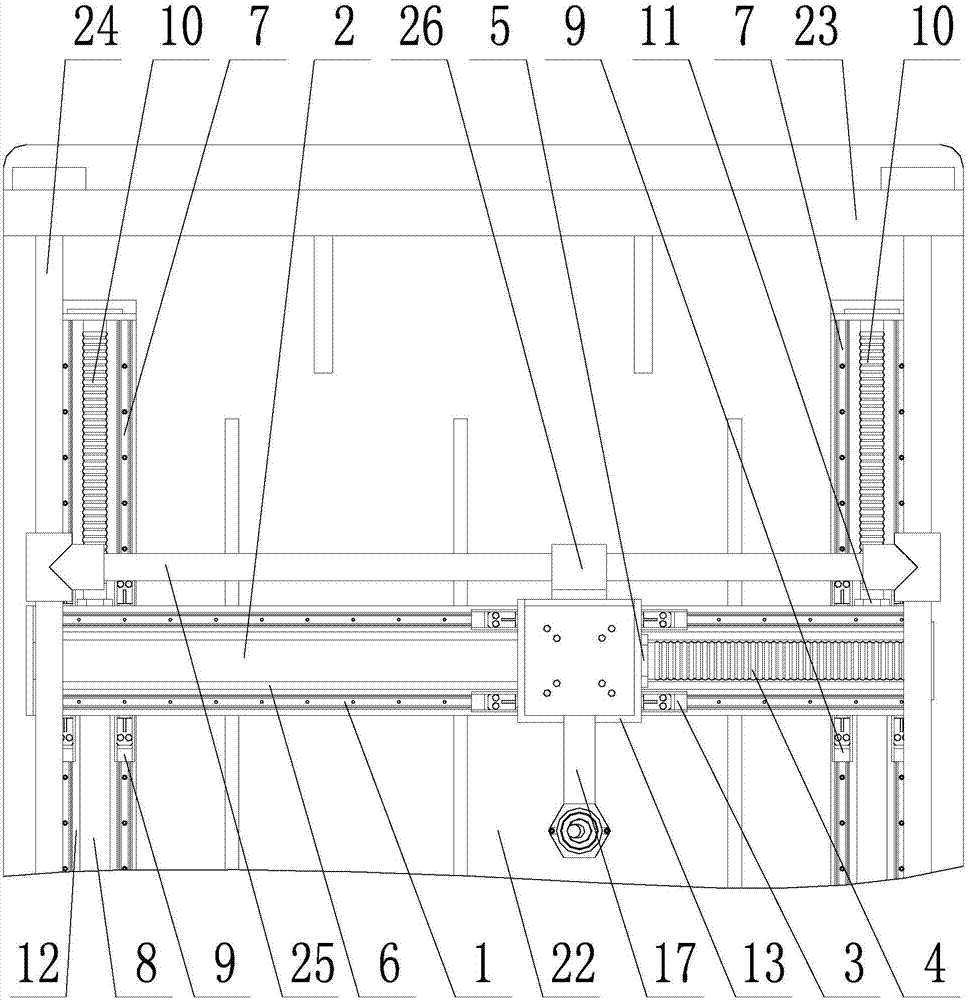

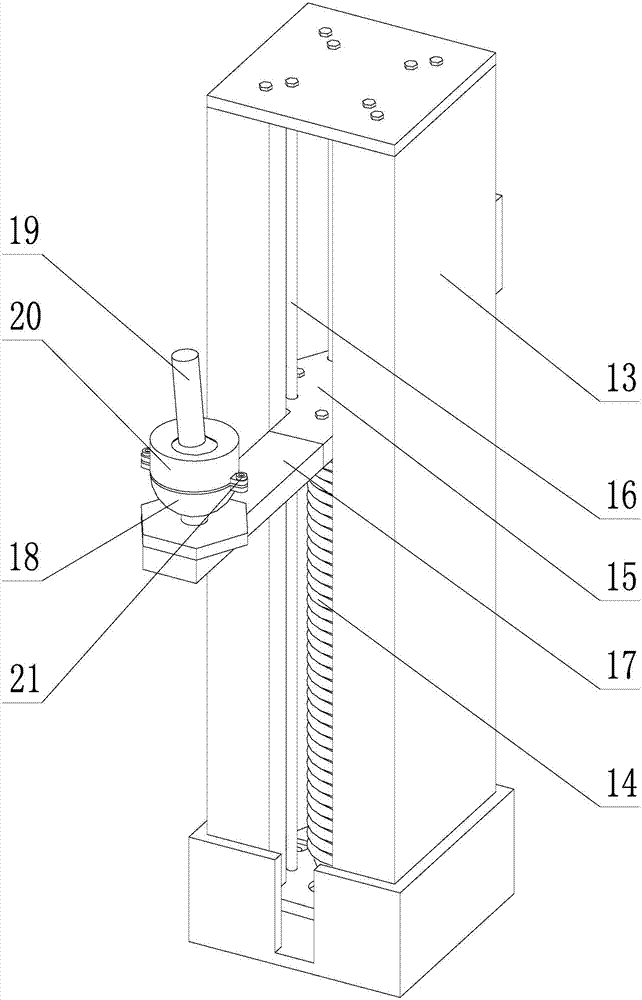

[0028] like figure 1 , 2 , 3, a five-axis double swing head gantry milling machine simulation cutting force loading device, including X-direction cutting force loading assembly, Y-direction cutting force loading assembly and Z-direction cutting force loading assembly, the X-direction cutting force loading assembly Including X-direction rail 1, X-direction rail mounting seat 2, X-direction slider 3, X-direction corrugated damping tube 4, X-direction damping tube guide flange 5 and X-direction damping tube guide optical axis 6; the Y-direction cutting The force loading assembly includes a Y-direction rail 7, a Y-direction rail mounting seat 8, a Y-direction slider 9, a Y-direction corrugated damping tube 10, a Y-direction damping tube guide flange 11 and a Y-direction damping tube guide optical axis 12; The Z-direction cutting force l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com