High-precision machining machine tool

A high-precision machining and machine tool technology, applied in metal processing machinery parts, metal processing equipment, manufacturing tools, etc., can solve the problems of single structure, unfavorable, and the position of the processing tool cannot be moved in all directions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

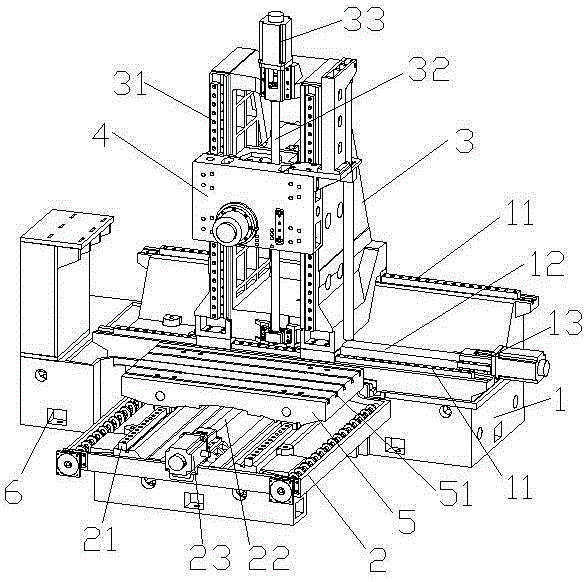

[0013] Such as figure 1 As shown, a high-precision processing machine tool includes a base 1, a support platform 2 is provided on one side of the base 1, and a workbench 5 that can move back and forth relative to it is provided on the support platform 2. On the base 1, A saddle 3 that can move left and right relative to it is provided, and a main shaft 4 that can move up and down relative to it is provided on the saddle 3, and a control cabinet 6 is also provided at one end of the base 1, wherein the base 1 is a step shape, the height of the workbench 5 is consistent with the height of the lower step surface of the base 1 .

[0014] By designing the saddle to move left and right relative to the base, designing the spindle to move up and down relative to the saddle, and designing the workbench to move forward and backward relative to the base, the spindle can adjust it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com