Stable microwave tea leaf fixation box

A greening box and microwave technology, applied in the tea treatment before extraction, etc., can solve the problems that the tea quality cannot be guaranteed, the emerald greenness is difficult to guarantee, and additional drying equipment is equipped, so as to avoid excessive greening, increase the service life, and use energy-saving equipment The effect of electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

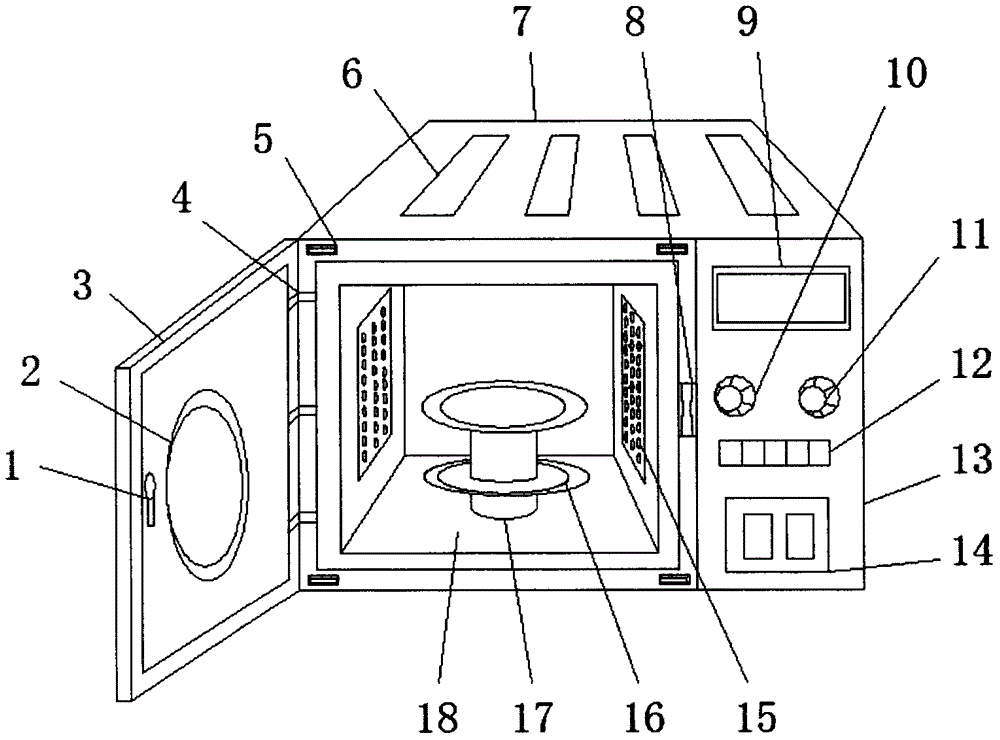

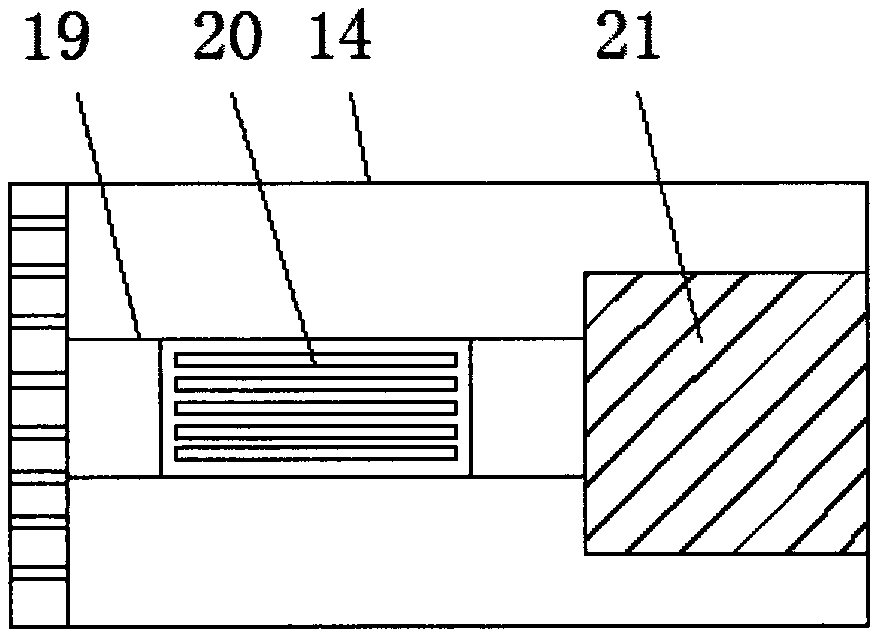

[0015] refer to Figure 1-2 , a stable microwave tea fixing box, including a box door 3, a housing 7, a control box 13 and a fixing box 18, a heat dissipation pipe 6 is installed on the upper side of the housing 7, and the housing 7 is connected to the box door through the opening and closing hinge 4 3 are connected, the tempered glass observation screen 2 is installed on the surface of the door 3, and the door buckle 1 is installed on the left side of the tempered glass observation screen 2, the card slot 8 is installed on the front surface of the housing 7, and the control panel is installed on the front surface of the housing 7. box 13, and a display screen 9 is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com