Composite material taking foam nickel as matrix and preparation method of composite material

A composite material, nickel foam technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of insufficient use of specific surface area, complicated operation, time-consuming and labor-intensive, etc. The effect of improving surface area and specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

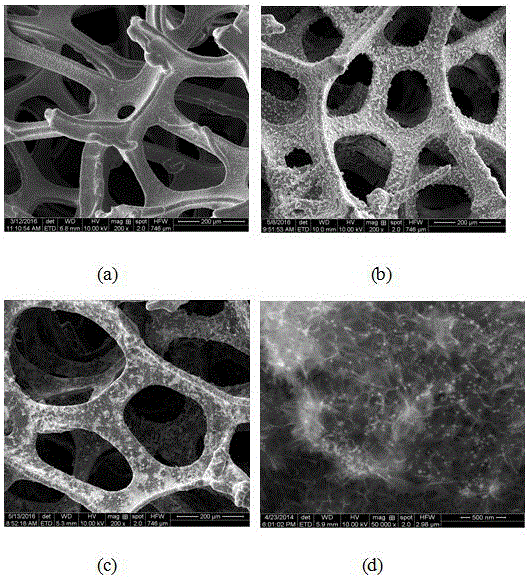

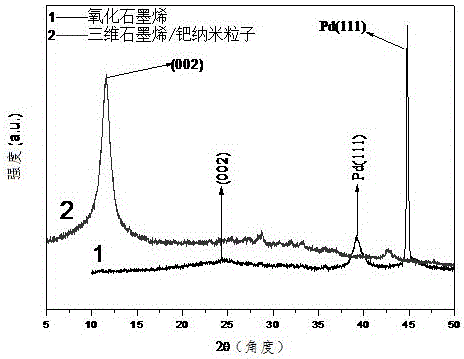

[0028] (1) Clean the nickel foam of 10mm*10mm*1mm with dilute hydrochloric acid, acetone and absolute ethanol for 13 minutes, then wash it with deionized water for 5 minutes and then dry it.

[0029] (2) Put 10 mg of graphene oxide prepared by the Hummers method in a beaker filled with distilled water, and sonicate in an ultrasonic instrument for 2 hours to obtain a concentration of 4 mg·ml -1 graphene oxide aqueous solution.

[0030] (3) Soak the nickel foam treated in step (1) directly into a graphene oxide aqueous solution beaker, and then sonicate and soak to form a nickel foam matrix material loaded with graphene oxide. During the ultrasonic immersion process, the reaction temperature is 30°C, the frequency is 40KHz, the ultrasonic is 20min, the interval is 5min, and the ultrasonic immersion is 20min, the total ultrasonic immersion time is 2 hours.

[0031] (4) Dry the prepared nickel foam substrate material loaded with graphene oxide, and then heat it up to 300°C at a r...

Embodiment 2

[0034] (1) Clean the nickel foam of 10mm*10mm*1mm with dilute hydrochloric acid, acetone and absolute ethanol for 12 minutes, then wash it with deionized water for 5 minutes and then dry it.

[0035] (2) Put 40mg of graphene oxide in a beaker filled with distilled water, and sonicate in an ultrasonic instrument for 2h to obtain a concentration of 3mg·ml -1 graphene oxide aqueous solution.

[0036] (3) Soak the nickel foam treated in step (1) directly into the graphene oxide aqueous solution beaker, and then ultrasonically soak to form a nickel foam matrix material loaded with graphene oxide. During the ultrasonic soaking process, the reaction temperature is controlled at 40 ℃, frequency 40KHz, ultrasonic 20min, interval of 5min, and then ultrasonic 20min, the total ultrasonic soaking time is 1 hour.

[0037] (4) The prepared nickel foam substrate material loaded with graphene oxide was dried, and then heated to 400°C at a heating rate of 5°C / min in a tube furnace under vacuum...

Embodiment 3

[0040](1) Put 5 mg of graphene oxide in a beaker filled with distilled water, and sonicate in an ultrasonic instrument for 2 hours to obtain a concentration of 6 mg·ml -1 graphene oxide aqueous solution.

[0041] (2) Soak 1cm*1cm*1mm nickel foam directly into a beaker of graphene oxide aqueous solution, and then ultrasonically soak to form a nickel foam matrix material loaded with graphene oxide. During the ultrasonic immersion process, the reaction temperature was controlled at 60°C, the frequency was 40KHz, the ultrasound was performed for 20 minutes, and the interval was 5 minutes, followed by another 20 minutes of ultrasound. The total ultrasonic immersion time was 3 hours.

[0042] (3) Dry the prepared nickel foam substrate material loaded with graphene oxide, then heat it up to 500°C in a tube furnace at a rate of 4°C / min under vacuum, take it out after holding for 2 hours, and obtain a three-dimensional Foamed nickel-graphene oxide composite product with porous structu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com