Junction finite element modelling method of bolt connection

A technology of screw connection and modeling method, which is applied in special data processing applications, instruments, electrical digital data processing, etc., to achieve the effect of meeting the needs of engineering calculations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

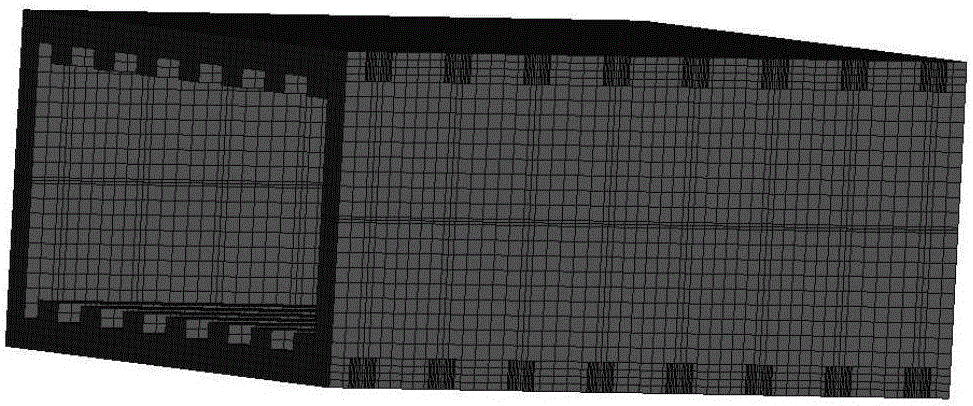

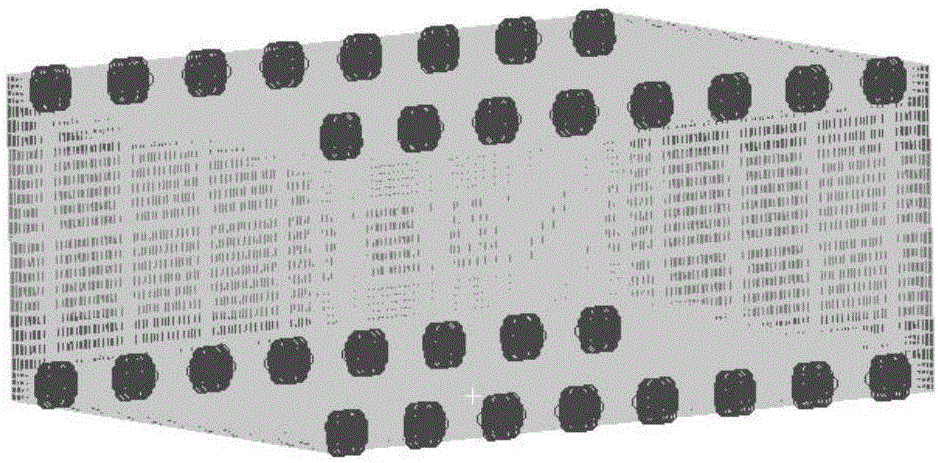

[0086] Taking a printed board fixture as an example of finite element modeling, the printed board fixture uses 32 A2-50 M4 screws to connect and fix four 5F05 aluminum plates together.

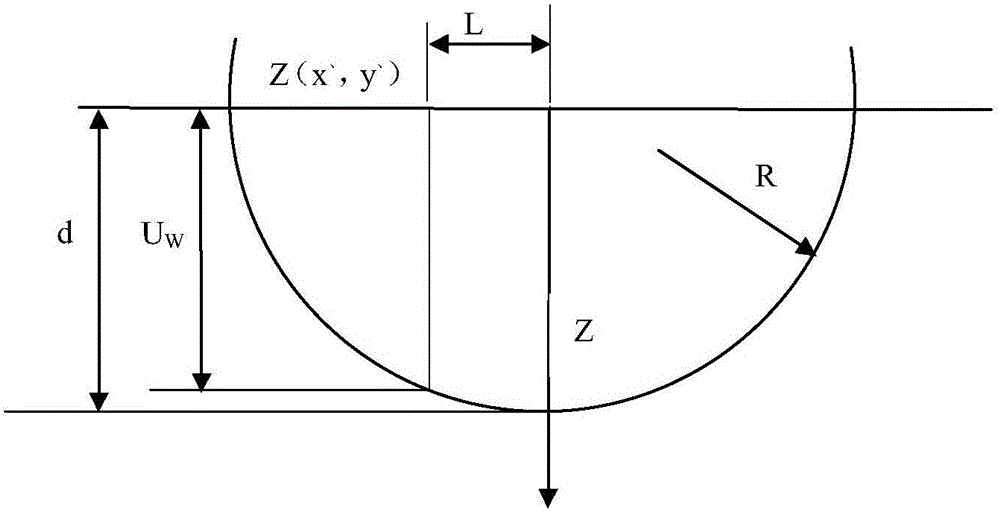

[0087] (1) Calculation of the diameter L of the effective contact area of screw connection parts

[0088] It is known that the elastic modulus of the aluminum plate connected by screws is E=70×10 9 Pa, roughness f=6.3×10 -6 mRa, In the actual application of the screw, the screw torque under the non-proportional elongation stress of 0.6 to 0.7 times is usually used as the pre-tightening torque, F N It is the compressive force generated under the action of this torque. The relevant parameters of the M4 screw of model A2-50 (GB819) can be found in the design manual as shown in Table 1 below:

[0089]

[0090] Table 1

[0091] According to the Hertzian contact theory and the G-W (Greenwood-Williamson) model, the calculation formula can be obtained as follows:

[0092] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com