Ferromagnetic thin-walled tube circumferential AC magnetization magnetic flux leakage detection array probe

A technology of magnetic flux leakage detection and array probes, which is applied in the direction of material magnetic variables, can solve problems such as difficulty and noise control, and achieve the effects of reducing influence, improving magnetic field uniformity, and enhancing anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

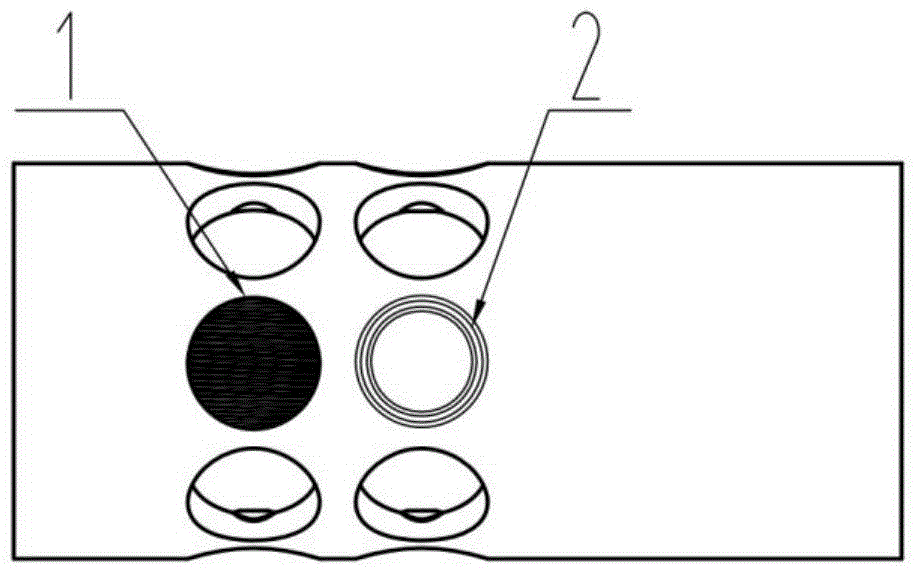

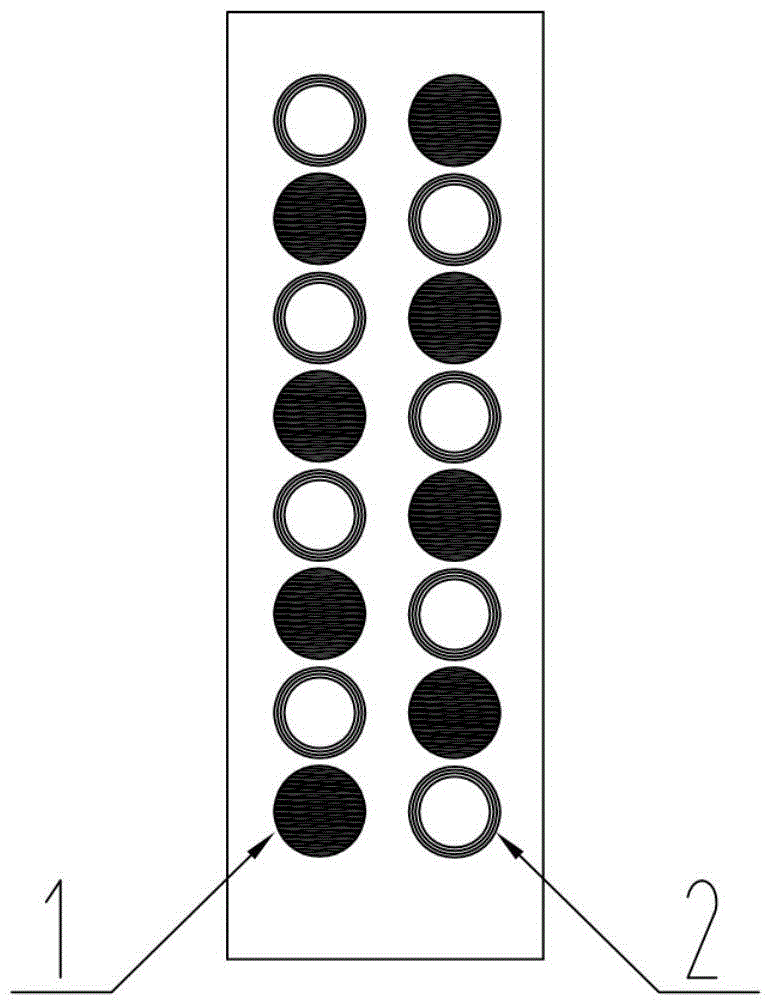

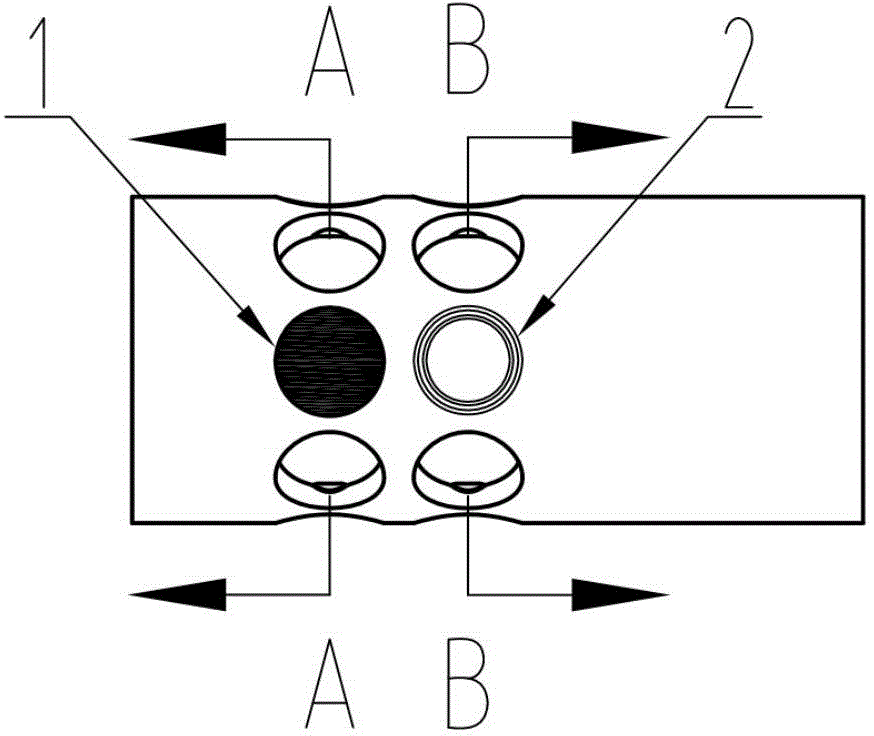

[0022] Such as figure 1 — Figure 5 As shown, the array probe for the circumferential AC magnetization flux leakage detection of ferromagnetic thin-walled pipes of the present invention includes two rows of giant magnetoresistance sensors 1 and excitation coils 2 uniformly distributed along the circumference of the pipe; each row of giant magnetoresistance sensors 1 and excitation coils The coils 2 are arranged at intervals, and the giant magnetoresistive sensors 1 and excitation coils 2 in the two rows are arranged alternately. The excitation coil 2 is a shaft-wound coil.

[0023] When detecting the pipeline, firstly excite the two adjacent excitation coils 2 on the first row of coils, and then realize the sequential excitation of other excitation coils 2 of this row of coils. After the sequence has completed the single row of coils (clock...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com