Dual-operation compression-ejection heat pump air conditioner system

A technology of heat pump air conditioning and dual working conditions, which is applied to compressors, compressors with reversible cycles, lighting and heating equipment, etc., which can solve the problems of ineffective recovery of expansion work and energy waste, and reduce the pressure ratio , Improve the utilization rate and improve the cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings, but the embodiments do not constitute any limitation to the present invention.

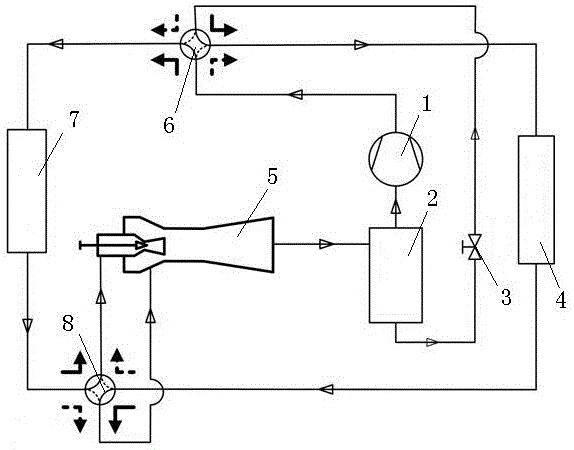

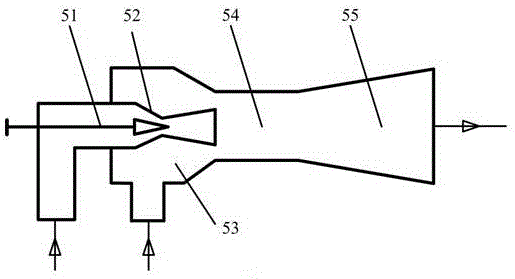

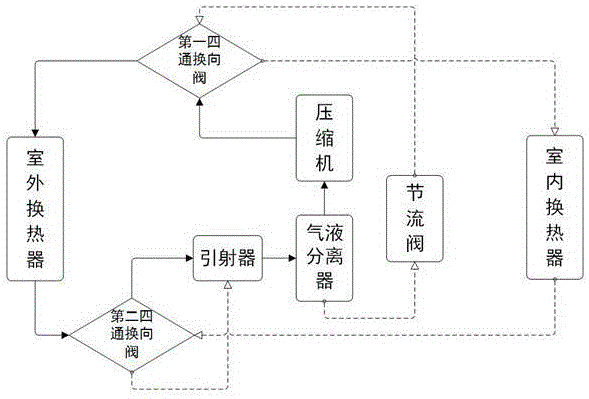

[0016] see figure 1 , figure 2 , double working condition compression-ejector heat pump air conditioning system, composed of compressor 1, gas-liquid separator 2, throttle valve 3, indoor heat exchanger 4, ejector 5, first four-way reversing valve 6, outdoor heat exchanger The heater 7 and the second four-way reversing valve 8 are composed. The ejector 5 has a spray needle 51, a working nozzle 52, a suction chamber 53, a mixing chamber 54, and a diffusion chamber 55. The working nozzle 52 is installed inside the suction chamber 53. , the suction chamber 53, the mixing chamber 54 and the diffuser chamber 55 are sequentially connected to form a two-phase working fluid processing chamber, and the outlet of the working nozzle 52 communicates with the two-phase working ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com