Liquid-phase pipe leakage irregular hole equivalent round hole experimental device and experimental method

A technology for pipeline leakage and experimental devices, which is applied in pipeline systems, gas/liquid distribution and storage, mechanical equipment, etc., can solve the problems of public safety threats, actual disconnection on site, and inability to accurately control the shape and size of leaks, and achieve rapid The effect of metering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing.

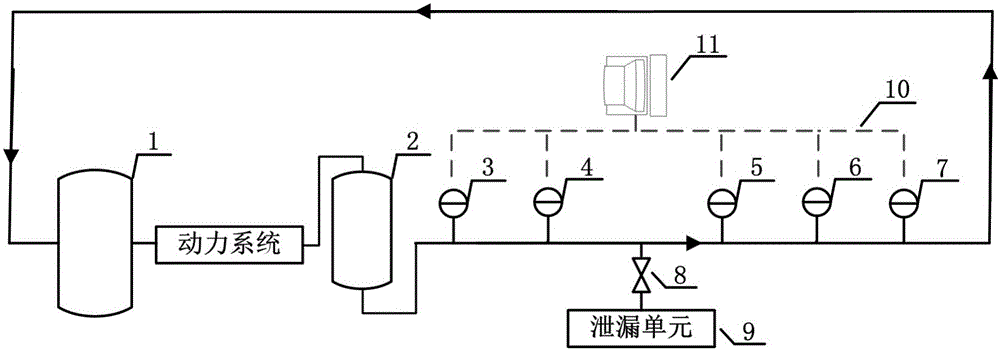

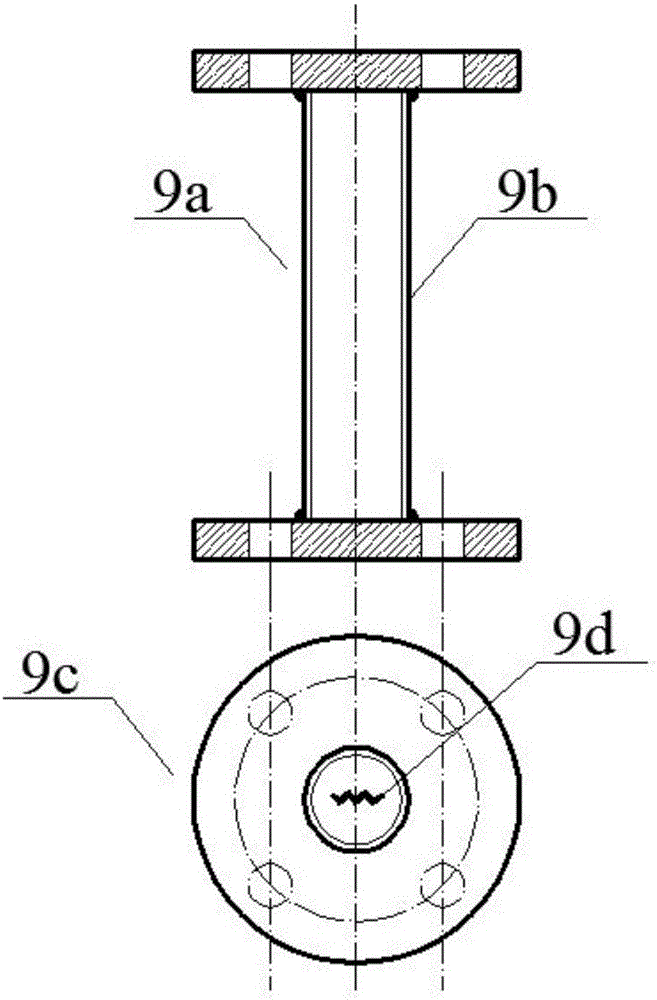

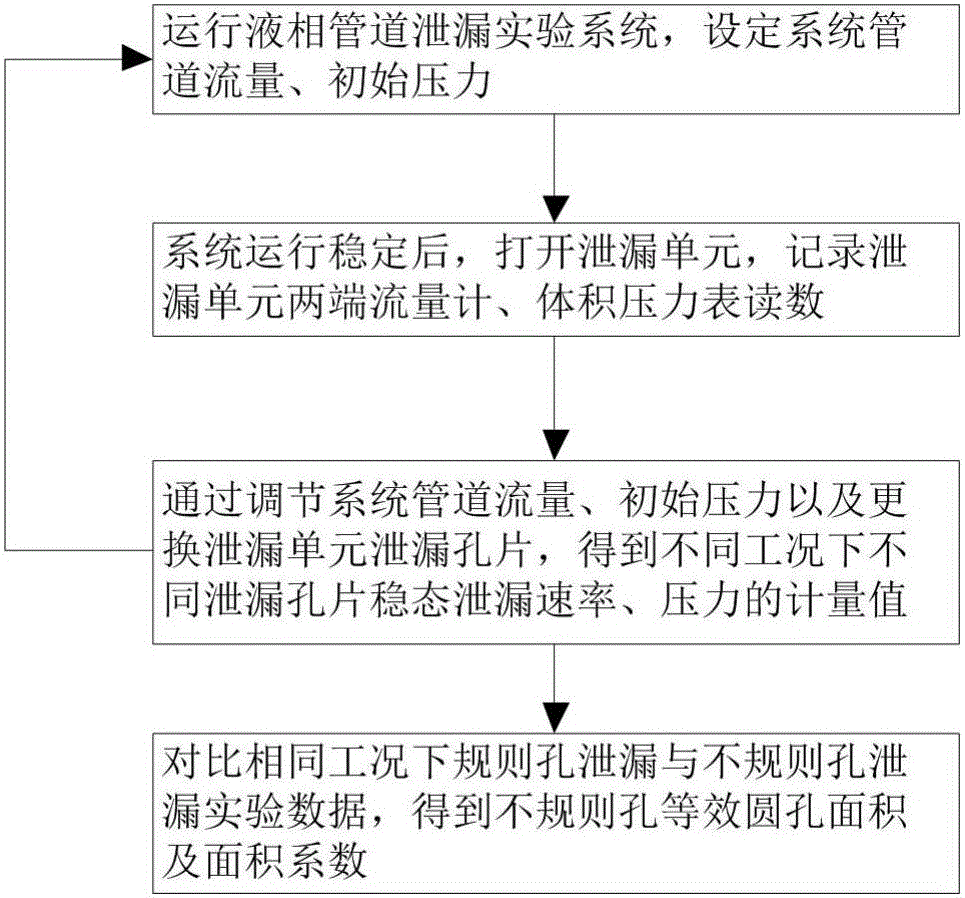

[0027] The liquid phase pipeline leaks an irregular hole equivalent to a round hole experimental device, including a storage tank 1, a power system, a buffer tank 2 and an infusion tube connected in sequence, wherein the two ends of the power system are respectively connected to the outlet of the storage tank 1 and the inlet of the buffer tank 2, and the infusion The two ends of the pipe are respectively connected to the outlet of the buffer tank 2 and the inlet of the storage tank 1; a leakage unit 9 is connected to the outside of the infusion pipe through a valve 8, and the leakage unit 9 includes a leakage pipe 9a and a leakage orifice 9c, and the first end of the leakage pipe 9a It is connected to the valve 8 through the leakage pipe wall 9b and the flange. The end of the leakage pipe 9a is connected with a leakage hole 9c through the leakage pipe wall 9b and the flange....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com