Automatic compensation type vacuum tube connecting device and dredging machinery with connecting device

A technology of automatic compensation and connection device, which is applied to expansion compensation device, adjustable connection, mechanical equipment and other directions for pipelines, can solve problems such as affecting the safety of driving operations, reducing the carrying capacity of vehicles, increasing the quality of the whole vehicle, etc. The effect of convenient installation and maintenance, reducing the weight of the whole vehicle and increasing the carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to further explain the technical solutions of the present invention, specific examples are given below to illustrate in detail.

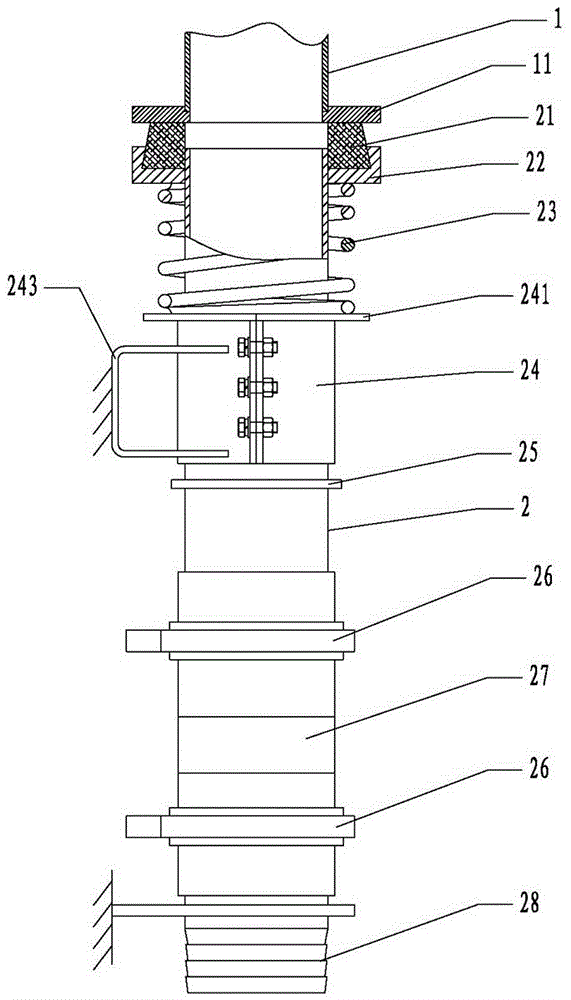

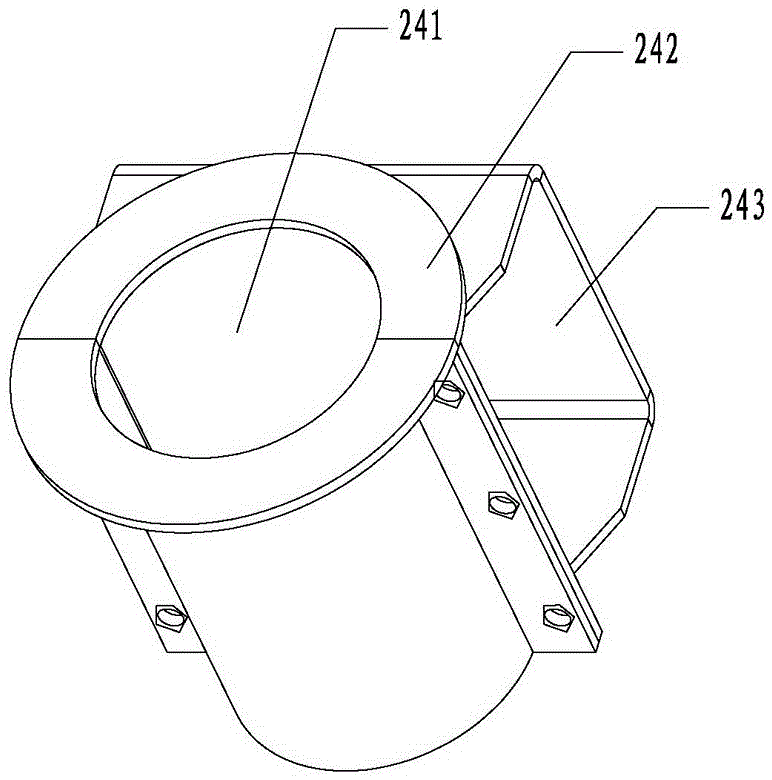

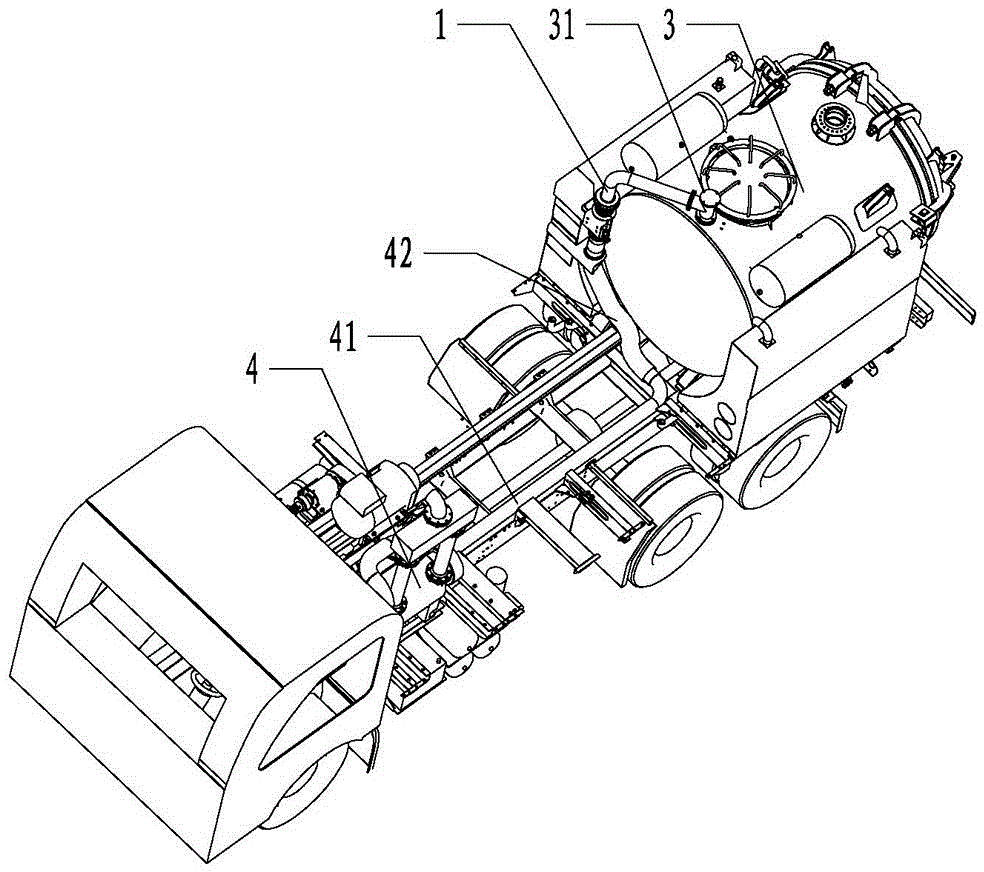

[0024] Such as Figure 1 to Figure 5 As shown, an automatic compensation type vacuum pipe connection device and dredging machine with the connection device include a dynamic connection pipe 1 and a static connection pipe 2 that acts as a connection guide. Among them, the dynamic connecting pipe 1 is a 90-degree bent pipe, and the upper horizontal end is provided with a flange connected to the side flange of the automatic shut-off valve 31 on the sewage tank 3, and the vertical lower end of the dynamic connecting pipe 1 is provided with a static connecting pipe 2 The ring flange 11 of the connecting end port sealing connection. On the static connecting pipe 2, the connecting end of the moving connecting pipe 1 is set with a sealing rubber 21, a concave ring 22, a spring 23 and a circular pipe guide seat 24 sequentially from top to bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com