Sealing assembly of mining double-chain scraper conveyer

A chain scraper and conveyor technology is applied in the field of sealing assemblies of mining double-chain scraper conveyors, which can solve the problems of shortening the service life of the seals, wear resistance, gaps on the sealing surface, etc., so as to prevent oil leakage, Long service life and good ring sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

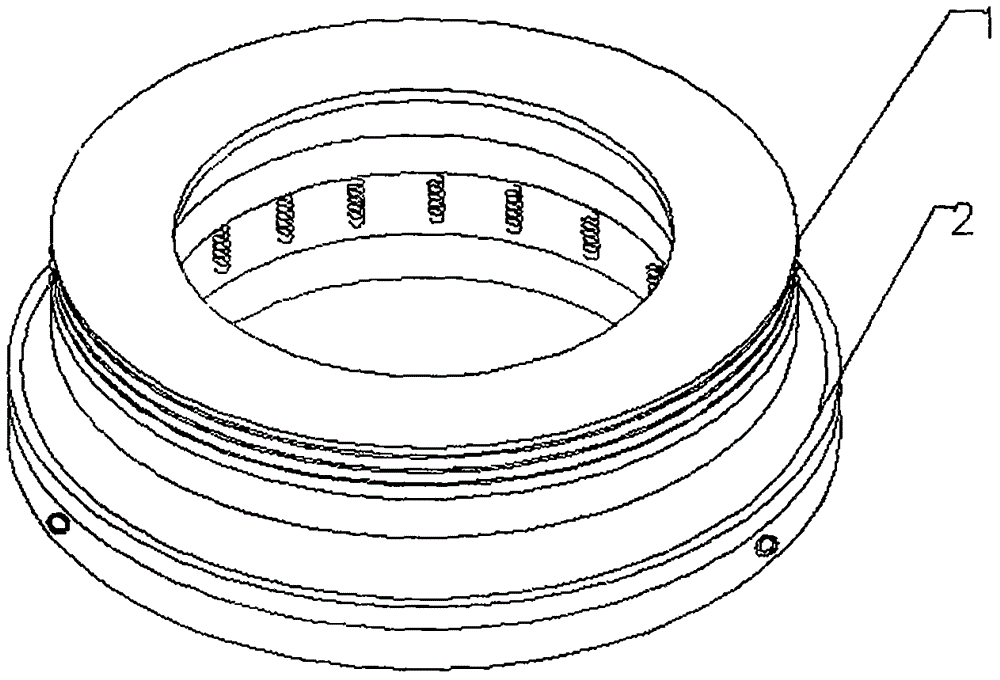

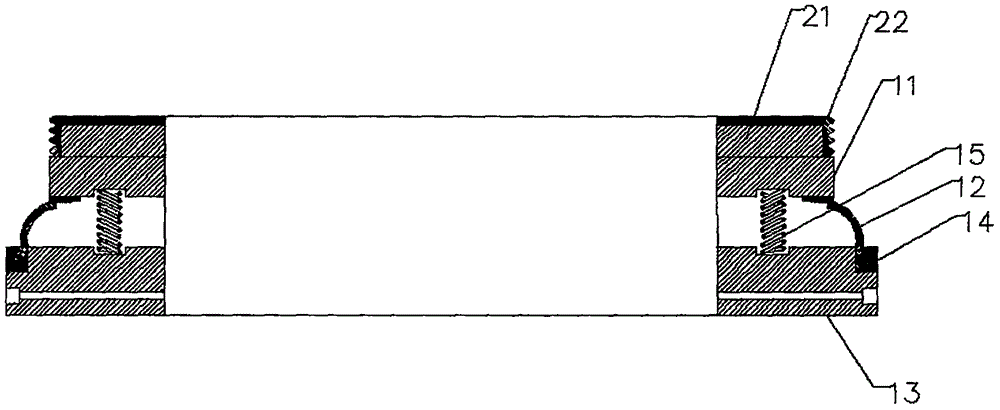

[0015] Such as Figure 1-2 As shown, a double-chain scraper conveyor seal assembly for mining includes a moving ring sealing sleeve (1) and a static ring sealing sleeve (2). The moving ring sealing sleeve (1) is fixed on a rotating shaft, and the static ring sealing sleeve (2) Press tightly on the moving ring sealing sleeve (1), and the butting surface of the moving ring sealing sleeve (1) and the static ring sealing sleeve (2) is smooth to form a sealing surface. The moving ring sealing sleeve (1) is composed of a lower sealing ring (11), a connecting piece (12), a connecting sleeve (13), a fixed sleeve (14) and a spring (15). The lower sealing ring (11) and the connecting sleeve (13) A connecting piece (12) and a spring (15) are arranged between ), and the lower part of the connecting piece (12) is fixed to the upper part of the connecting sleeve (13) through a fixing sleeve (14). The lower sealing ring (11) is cast from a titanium alloy, and the upper surface of the lower s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com