Dual-fuel oil supply system for marine diesel engine

A technology of marine diesel engine and oil supply system, which is applied in the field of oil supply system of marine diesel engine, can solve the problem of ignoring the difference of fuel oil viscosity and lubricity, achieve good economic and social benefits, free oil circuit conversion, and prolong service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is described in more detail below in conjunction with accompanying drawing example:

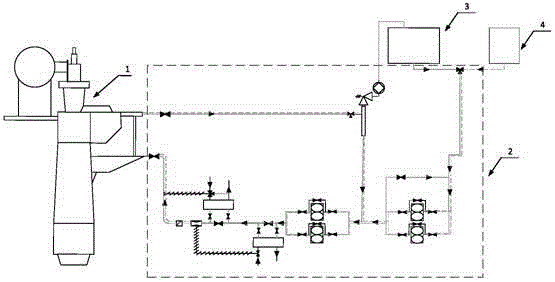

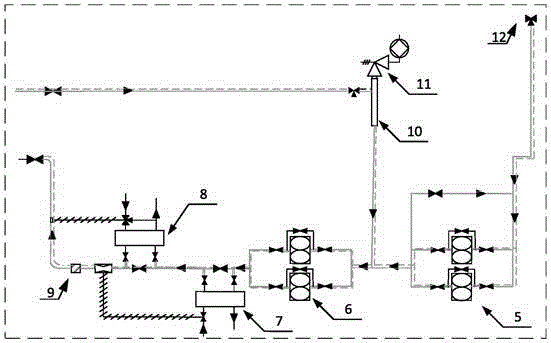

[0016] combine Figure 1~2 , a dual-fuel oil supply system for marine diesel engines of the present invention includes a main engine 1, an oil supply unit 2, a high-sulfur oil tank 3 and a low-sulfur oil tank 4; the main engine 1 is connected to the oil supply unit 2 through an oil circuit; The high-sulfur oil tank 3 and the low-sulfur oil tank 4 are connected to the oil supply unit 2 through an oil circuit. The fuel supply unit 2 includes: a fuel delivery pump 5, a fuel circulation pump 6, a fuel heater 7, a low-sulfur oil cooler 8, a full-flow filter 9, a fuel return cylinder 10, an automatic degassing valve 11 and Oil supply three-way valve 12. One end of the fuel delivery pump 5 is connected to the high-sulfur fuel tank 3 and the low-sulfur fuel tank 4 respectively, and the other end is connected to the fuel oil return cylinder 10; the fuel oil return cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com