Wall for hot gas channel in gas turbine

A gas turbine, hot gas technology, applied in the cooling, combustion chamber, combustion method of turbine/propulsion device, etc., can solve problems such as limited life, and achieve the effect of increasing tolerance and increasing quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

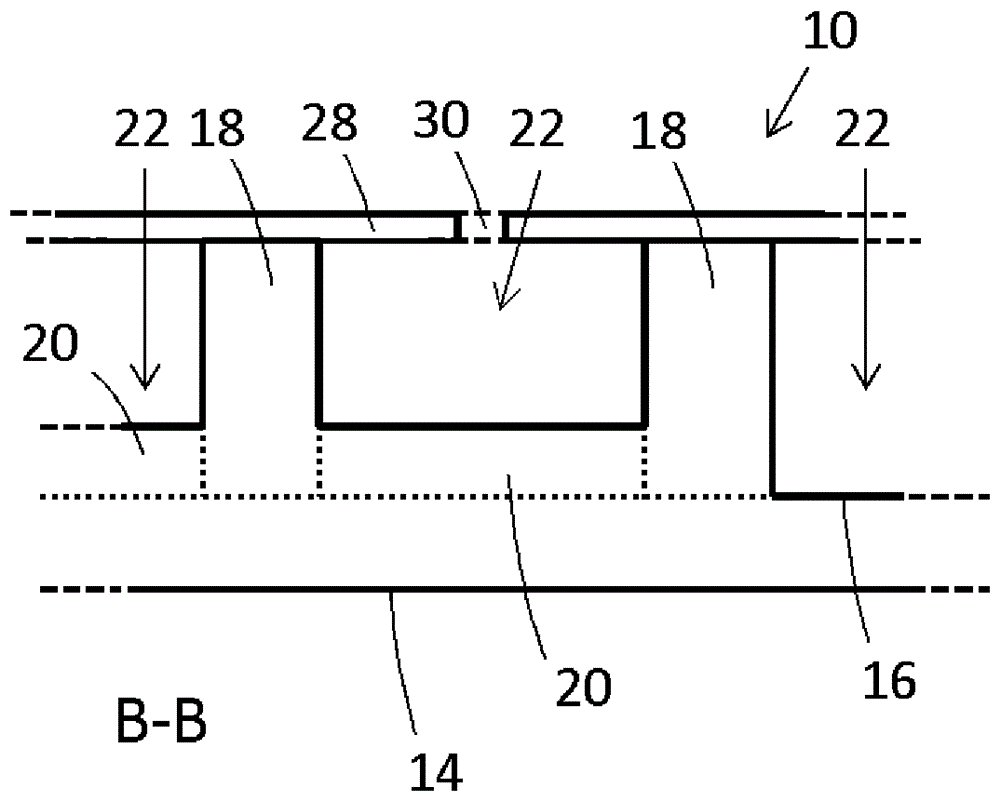

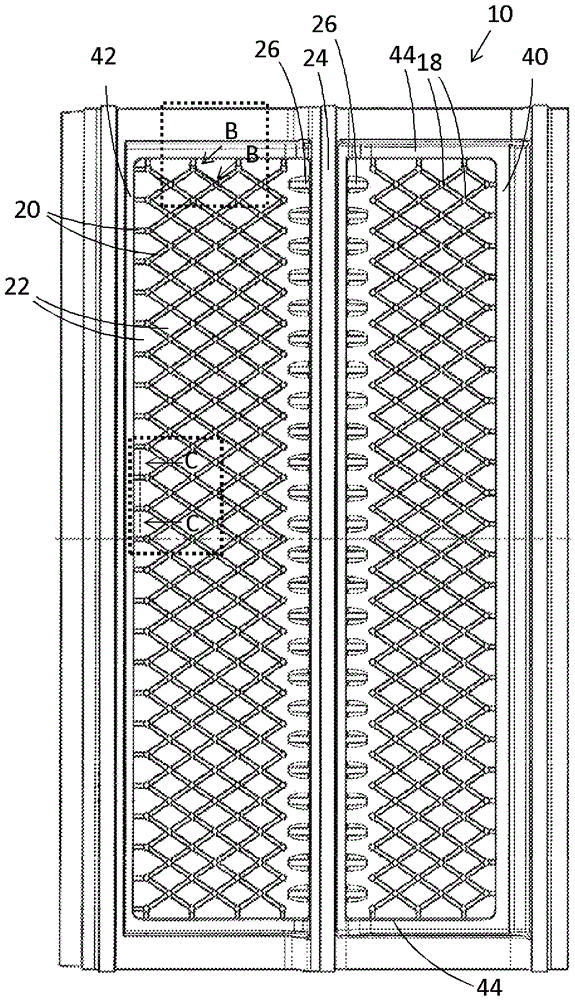

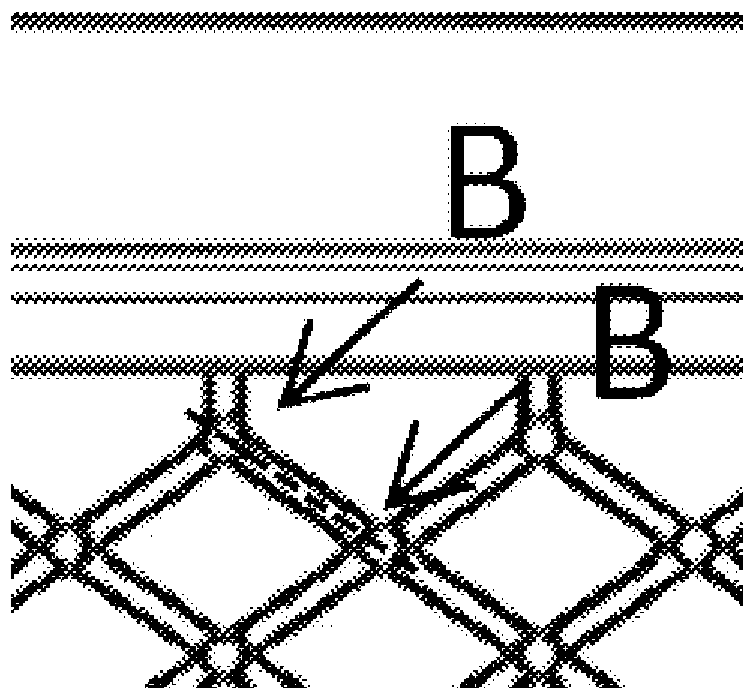

[0043] figure 1 and figure 2 (along figure 1 The cross-section of B-B in ) shows a wall 10 for a gas turbine exposed to a hot fluid, such as hot exhaust gas on the positive side 14 . On the back side 16 of the wall are attached an array of pins 18 . Ribs 20 extend between the pins and are attached to both the pins and the rear wall. The ribs define the cell 22 on the back side of the wall.

[0044] Optionally, a second wall 24 may be provided which is attached to the back side 16 of the wall and is substantially or completely perpendicular to the back side 16 . Stiffening ribs 26 may be attached to the wall and the second wall for structural support.

[0045] figure 2 Also shown is a strike plate 28 which is added near the pin. Impingement cooling holes 30 may be provided in the impingement plate 28 . The impingement cooling holes are typically located on the center of the element 22 such that figure 2 The impingement cooling holes shown in are actually set back be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com