Method for analyzing oil-water emulsification behavior in near wellbore area and perforation blasthole

A near-well zone, oil-water emulsification technology, applied in wellbore/well components, earthwork drilling, measurement, etc., can solve the problem of energy without direction scalar, etc., and achieve the effect of easy analysis, simple model and clear principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is further described below:

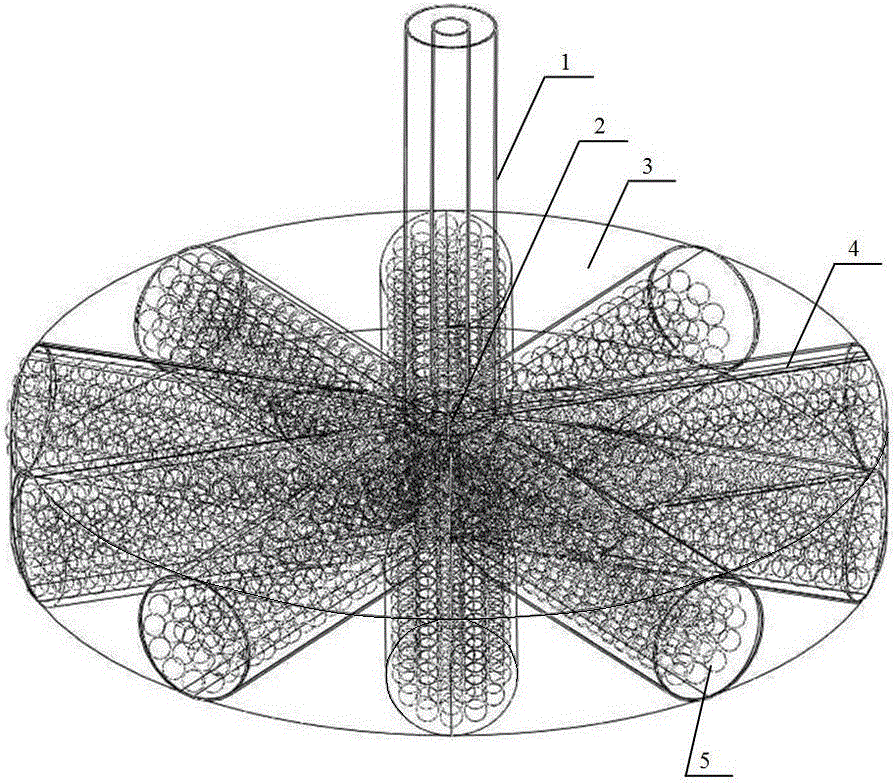

[0027] The method of using shear energy to analyze the oil-water emulsification behavior in the near-wellbore zone and the perforated blasthole described in the present invention is as follows: figure 1 As shown in the figure, the oil-water emulsions with different degrees of stability of flow shearing through the radial zone 3 in the near-wellbore zone and the perforation hole 2 flow into the vertical wellbore 1 to realize subsequent crude oil production and transportation. The radial region 3 in the near wellbore zone is equivalent to several equivalent circular tubes 4 that are radially arranged and filled with reservoir rock particles 5 and have the same specifications and dimensions. In this way, the flow field shear in the near-wellbore zone and the perforated blasthole area is equivalent to the flow shear in the circular tube that can obtain similar flow field distribution characteristics, and is a theoretical m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com