SRC shear walls constrained by steel sleeves at the root regions at both ends

A technology of concrete shear wall and root area, applied in the direction of walls, buildings, building components, etc., can solve the problems of poor seismic performance, brittle failure, etc., to improve the ductile deformation ability, improve the bending deformation ability, and coordinate the deformation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is described in detail below in conjunction with accompanying drawing:

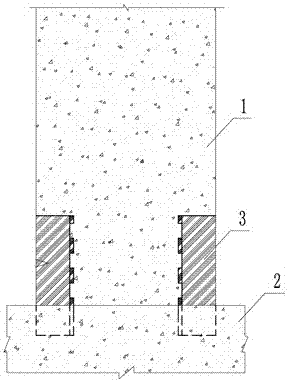

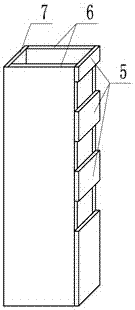

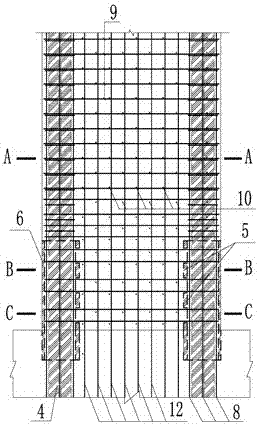

[0021] Such as figure 1 , image 3 as well as Figure 4A , Figure 4B and Figure 4C As shown, the steel sleeve of the present invention constrains the steel concrete shear wall in the root region of both ends to be composed of a concrete wall 1, a wall foundation 2, a steel sleeve 3, a vertical section steel 4 in the hidden column area at the end of the wall, and a hidden column area. The longitudinal reinforcement 8 and the stirrup 11, the web distribution transverse reinforcement 9 and the longitudinal reinforcement 12 are composed.

[0022] Steel sleeves 3 are provided at both ends of the steel concrete shear wall close to the root of the section steel 4 to form a restraint area for the concrete at the bottom of both ends of the wall 1; the bottom of the steel sleeve 3 extends into the wall foundation 2, and the length of the extension is One-half the thickness of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com