System for producing glass fiber chopped strand mats

A production system and glass fiber technology, applied in the field of sedimentation chamber, can solve the problems of untimely adjustment, excessive waste, poor adjustment accuracy, etc., and achieve the effects of improving production efficiency, uniform blanking, and convenient observation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation of the present invention will be further described below in conjunction with the examples.

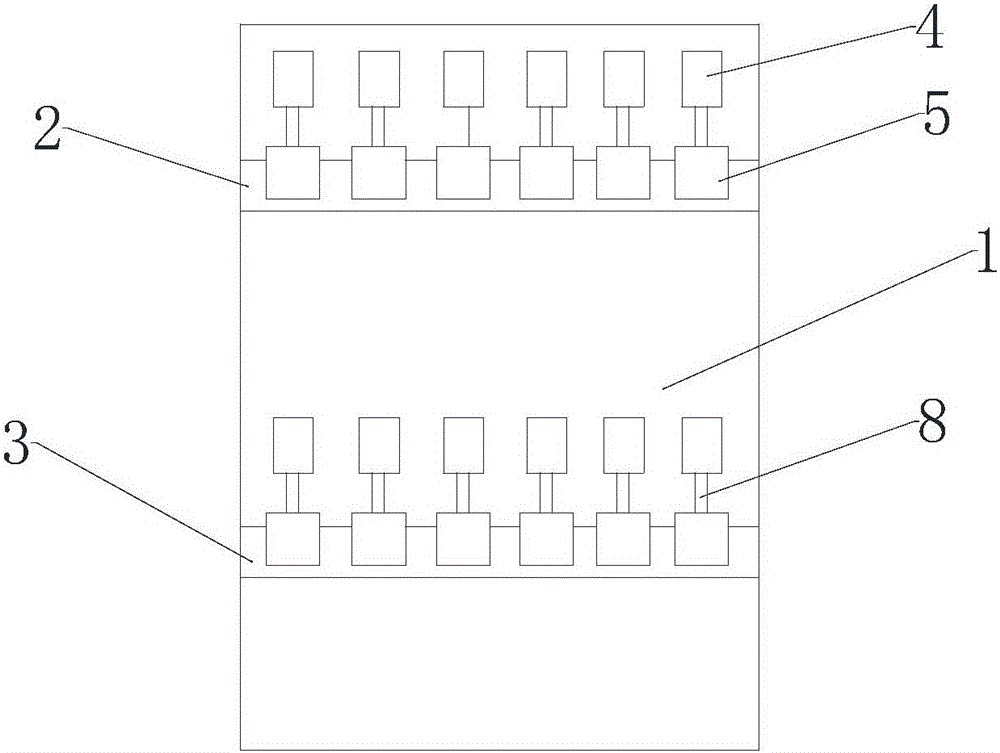

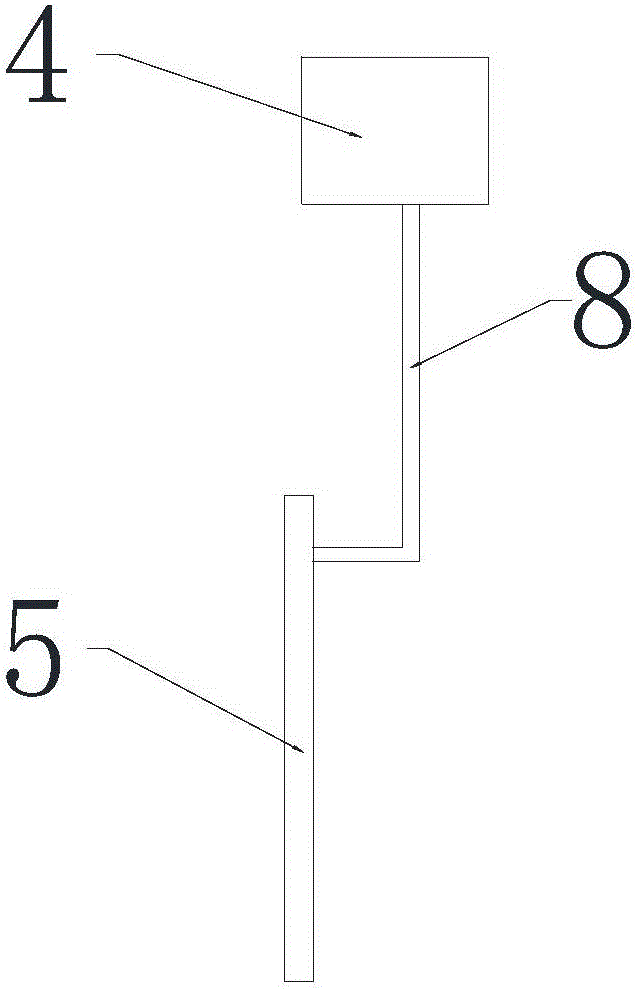

[0021] Such as Figure 1 to Figure 4 As shown, a production system of glass fiber chopped strand mat includes a cutting device for glass fiber yarn clusters, a settling chamber, a water spray device, a powder spreading device, a drying device, a compacting device, a detection device, and a collection device arranged in sequence. Rolling device, the settling chamber includes a settling chamber body, the settling chamber body is provided with an air inlet, the air inlet is a long strip-shaped through hole arranged on the side wall of the settling chamber body, and the air inlet is provided with several damper assemblies, The damper assembly includes a damper and a driving device connected to the damper, two adjacent dampers are provided with intervals, the intervals are the same size, the driving device is an electric cylinder, and a control unit for co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com