Dry-mixed plastering mortar additive and application thereof

A plastering mortar and additive technology, which is applied in the field of building materials, can solve the problems of accelerated mortar, poor durability of mortar, and shrinkage of strength, etc., and achieve the effects of small construction workability loss, strong shrinkage resistance, and good plastering performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

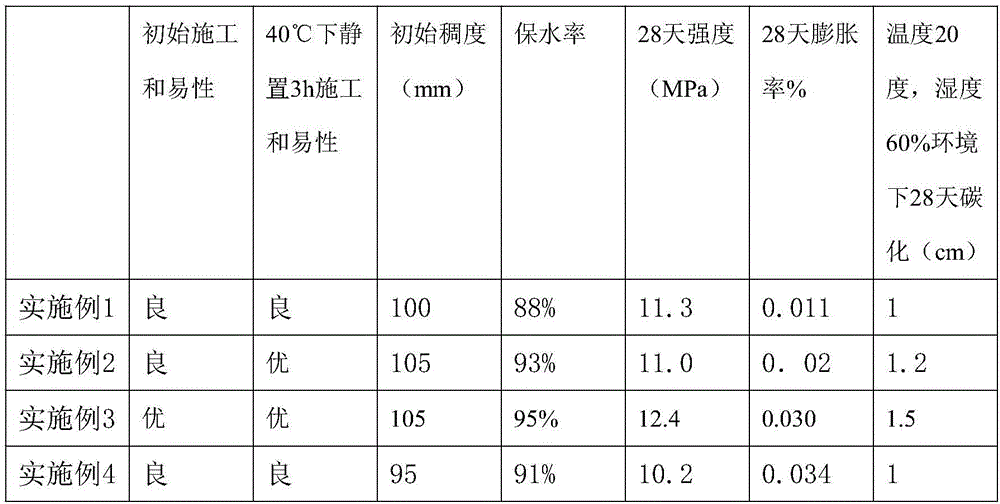

Examples

Embodiment 1

[0022] An additive for dry-mixed plastering mortar, comprising the following content: 0.01% of hydroxyethyl methylcellulose, 0.01% of magnesium aluminum silicate, 0.5% of mineral microcrystals, 0.5% of bentonite, and 1% of calcium oxide %, CaSO2 content is 1%, and the rest is mixed with water to form mortar additives.

[0023] Take 100kg of cement, 50kg of coal ash, 1000kg of sand, 50kg of mortar additives, and 150kg of water and mix them to obtain building mortar.

Embodiment 2

[0025] An additive for dry-mixed plastering mortar, comprising the following components: 0.03% of hydroxyethyl methylcellulose, 0.03% of magnesium aluminum silicate, 0.9% of mineral microcrystals, 0.7% of bentonite, calcium oxide The content is 1.6%, the CaSO2 content is 1.5%, and the rest is water.

[0026] Take 150kg of cement, 70kg of coal ash, 1650kg of sand, 60kg of mortar additives, and 200kg of water and mix them to obtain building mortar.

Embodiment 3

[0028] An additive for dry-mixed plastering mortar, comprising the following components: 0.05% of hydroxyethyl methylcellulose, 0.05% of magnesium aluminum silicate, 1% of mineral crystallite, 1% of bentonite, calcium oxide The content is 1.5%, the CaSO2 content is 2%, and the rest is water.

[0029] Take 160kg of cement, 70kg of coal ash, 1480kg of sand, 60.5kg of mortar additives, and 290kg of water and mix them to obtain building mortar.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com