Device and method for quicklime digestion, dedusting and sewage sludge treatment

A sewage treatment device, quicklime technology, applied in sludge treatment, dewatering/drying/concentrating sludge treatment, chemical instruments and methods, etc., can solve the problems of poor digestion effect, low digestion efficiency of digester, dust and flue gas pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

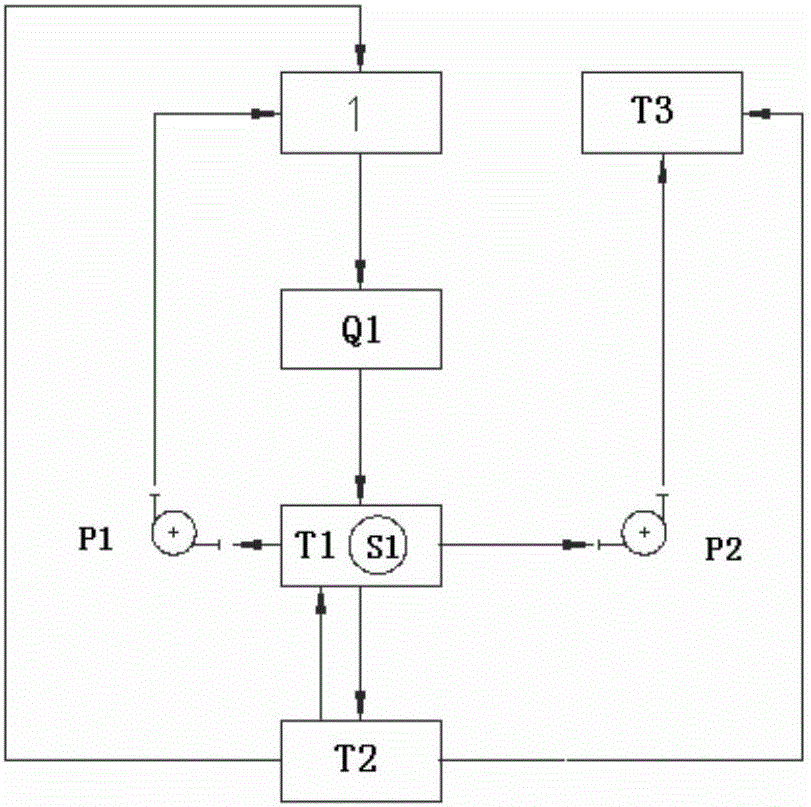

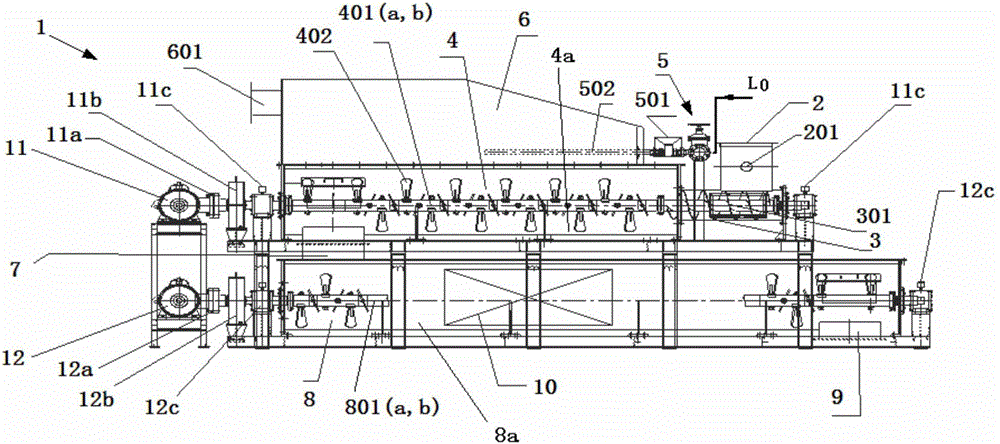

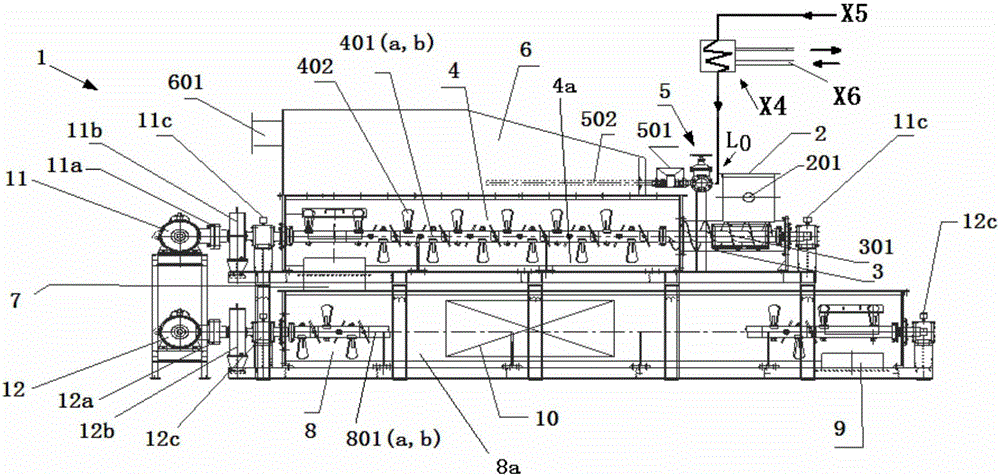

[0108] According to the first embodiment of the present invention, quicklime digestion, dust removal and sewage treatment equipment are provided, which includes: quicklime digester 1, water bath dust collector Q1 and sewage treatment equipment, wherein the sewage treatment equipment includes sewage tank T1, is arranged on the sewage tank Stirring device S1, sewage pumps P1, P2 and sludge dewatering machine T2, and the quicklime digester 1 is equipped with a sealed dust cover 6 with a dust collection external interface 601, and the water bath dust collector Q1 is connected to the digester 1 through a dust removal pipeline Q4 The dust collection external interface 601 is connected, and the bottom of the water bath dust collector Q1 has a dust removal sewage pipe connected to the above sewage pool.

[0109] Preferably, the quicklime digester is a two-stage quicklime digester 1, which includes: a feed port 2, a sealed delivery section box 3 whose front end communicates with the fee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com