A method of using polycaprolactone and ceramsite to strengthen denitrification in constructed wetlands

A technology of polycaprolactone and constructed wetland, which is applied in the field of water treatment, can solve the problems of unstable effluent quality, harm to the indigenous microorganisms in the receiving water body, etc., and achieve the effect of stabilizing the microbial population

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

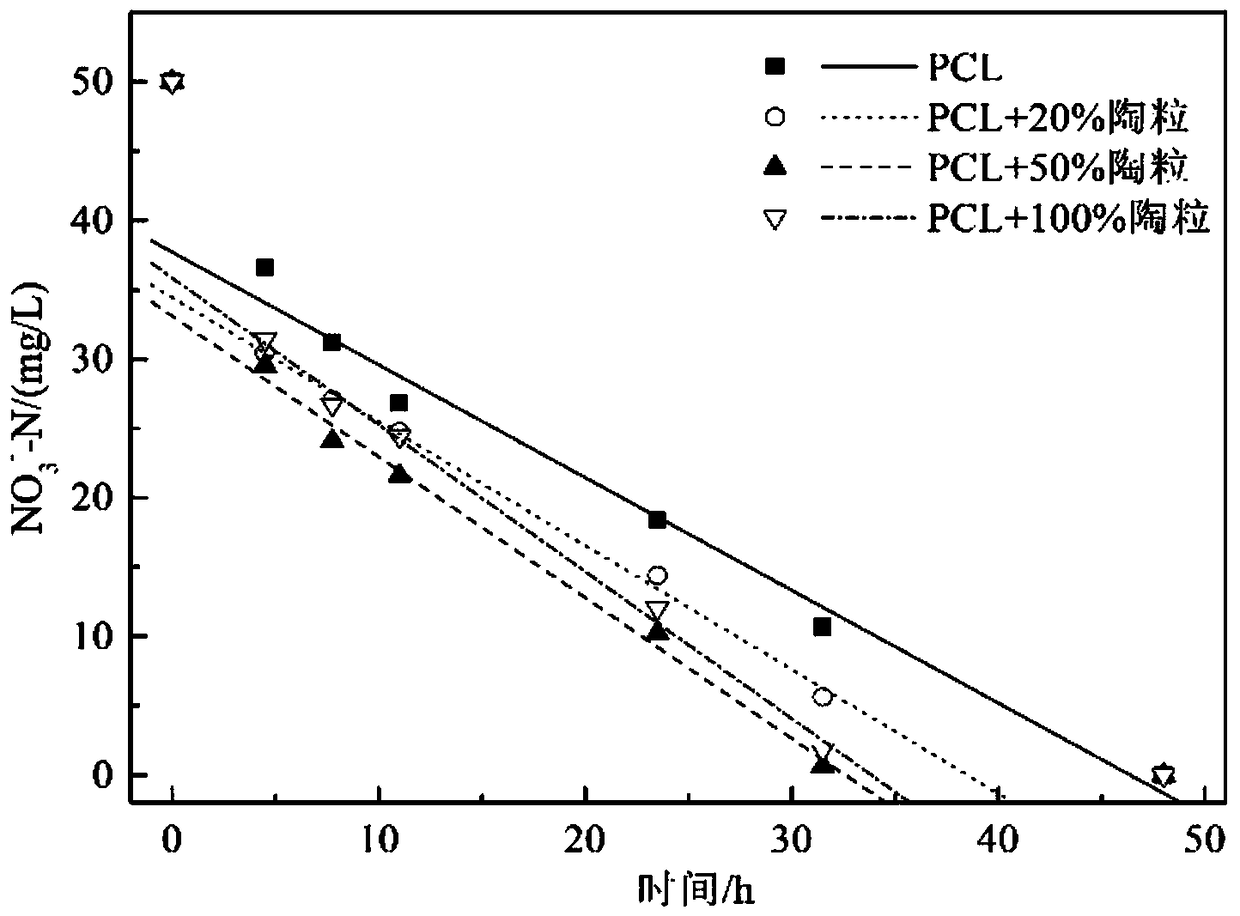

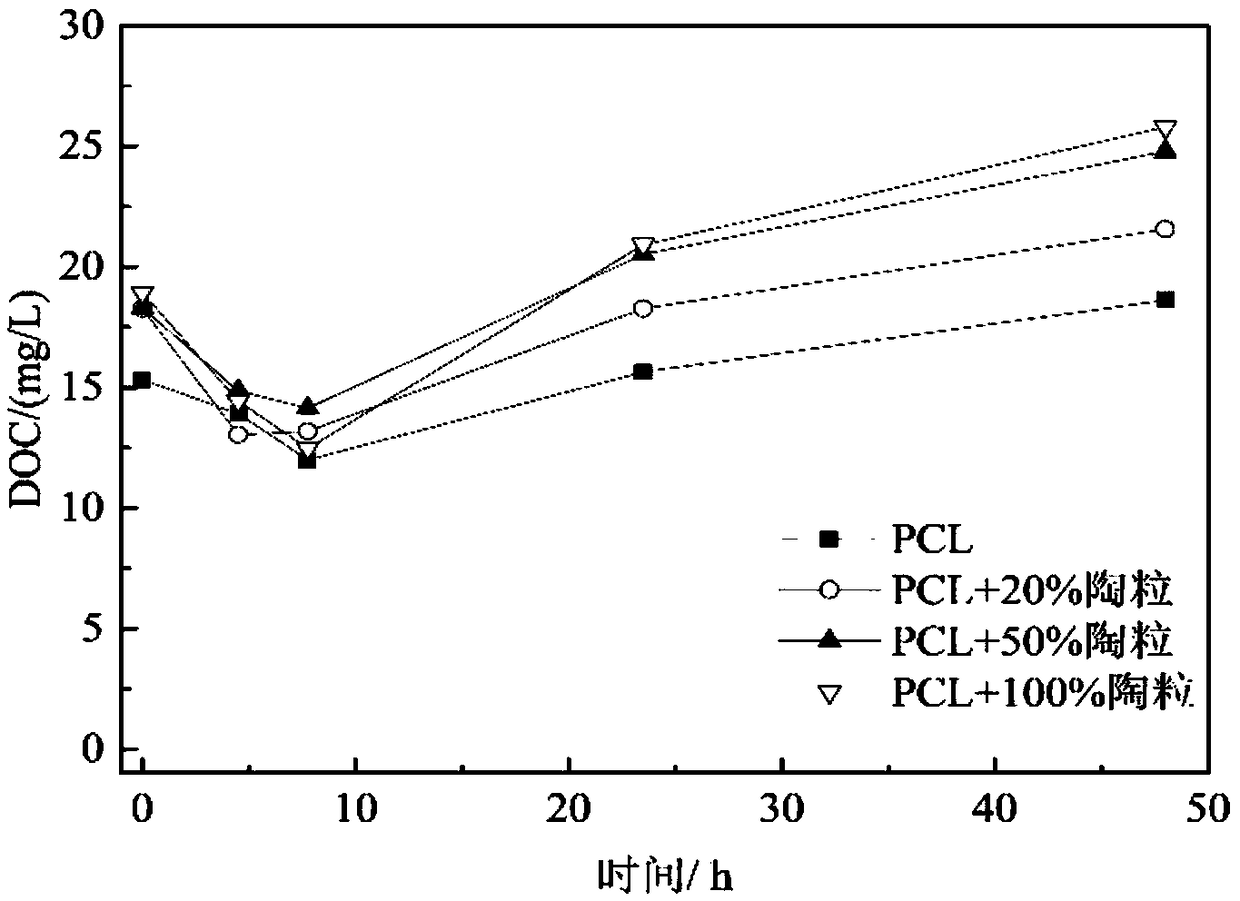

[0034] Example 1 Influence of different proportions of PCL and ceramsite layer on denitrification effect and DOC in constructed wetland

[0035] Acclimatization: A small filter column in the laboratory is used to simulate the carbon source layer of the constructed wetland. In four 1500mL cylindrical plexiglass columns, the matrix obtained by blending ceramsite and polycaprolactone (PCL) at a mass ratio of 0, 1:5, 1:2, and 1:1 was respectively added, which were recorded as the experimental group 1 (PCL), experimental group 2 (PCL+20% ceramsite), experimental group 3 (PCL+50% ceramsite) and experimental group 4 (PCL+100% ceramsite). And added with 30.00mg / L NO 3 - -N and 6.00mg / L PO 4 3- -P 1000mL of surface water. After sealing, put it into a constant temperature incubator at 25°C for reaction. Given that ceramsite for NO 3 - The inertness of -N adsorption, and the pertinence of the experimental conditions (simulating the actual in-situ treatment, without shaking, and n...

Embodiment 2

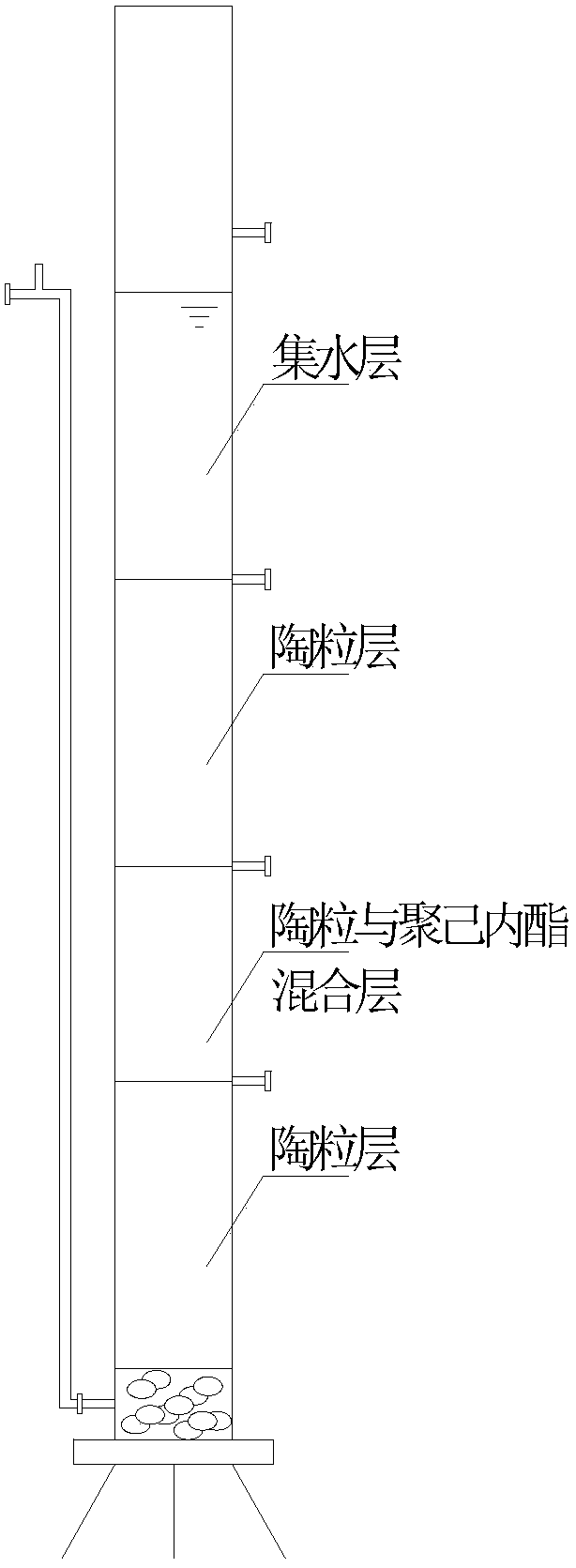

[0045] The simulated vertical subsurface flow constructed wetland is divided into water inlet area, filter area and water outlet area from top to bottom. The water inlet area is connected to the water inlet pipe, and the filter area is filled with ceramsite, ceramsite and polycaprolactone mixed filter media from top to bottom. , Ceramsite, the outlet area is connected to the outlet pipe. The simulated artificial wetland is made of plexiglass, with an inner diameter of 10cm and a total height of 100cm. The reactor is divided into 5 layers in total. From bottom to top, there are 5cm pebble layer, 20cm ceramsite layer, 15cm ceramsite and polycaprolactone mixed layer, 20cm ceramsite layer and 20cm water collection layer. The total volume of the reactor is 2.34 L.

[0046] The main pollutant in surface water is NH 4 + -N, NO 3 - -N, NO 2 - -N, TOC, the concentration of each pollutant is 0-1.45mg / L, 0-30.00mg / L, 0-0.40mg / L, 0-7.2mg / L respectively.

[0047] 1. Experimental se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com