A composite oil-absorbing cotton for cleaning oily spots on water

A technology of oil-absorbing cotton and oil flower, applied in the direction of synthetic resin layered products, layered products, wood layered products, etc., can solve the problems of high toxicity of dispersants, waste of oil dispersants, high cost, etc., and achieve good liquid absorption performance , improve absorption efficiency, fast absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

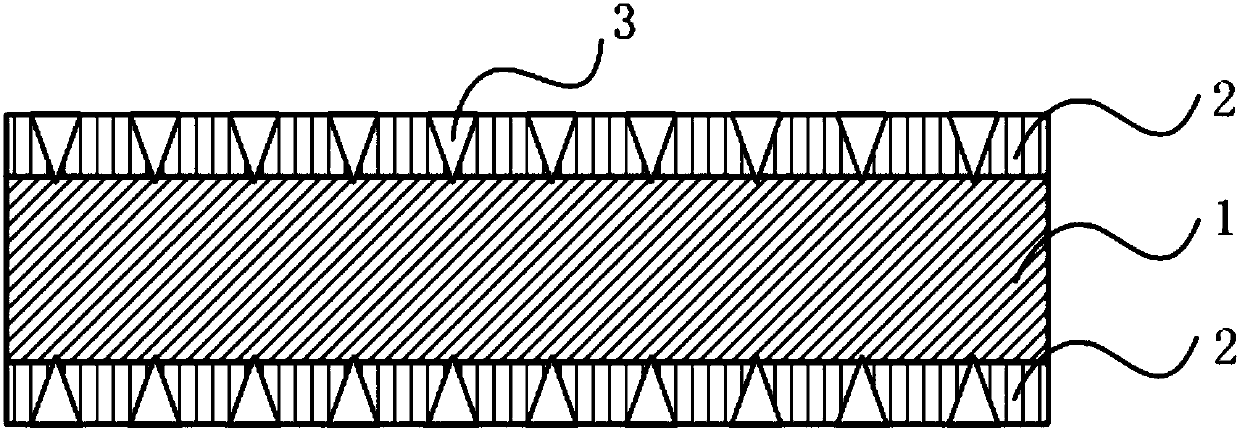

[0031] A composite oil-absorbing cotton for cleaning oily spots on water, comprising an oil-absorbing cotton body 10, the oil-absorbing cotton body 10 comprising an oil-absorbing layer 1 and a hydrophilic film layer 2 fixed on the oil-absorbing layer 1, the hydrophilic film The material of layer 2 is non-woven fabric composited with polyester and wood pulp fiber, the material of the oil-absorbing layer 1 is polypropylene, and the hydrophilic film layer 2 is provided with several oil seepage holes 3 .

[0032] Further, as figure 1 As shown, the number of the hydrophilic film layer 2 is two layers, which are respectively fixed on the upper surface and the lower surface of the oil-absorbing layer 1, so as to ensure more fully absorbing the oil spray on the water surface.

[0033] Further, the material of the hydrophilic film layer 2 is polyester and wood pulp fiber composite pressure point non-woven fabric, especially polyester and wood pulp fiber composite pressure point spunlac...

Embodiment 2

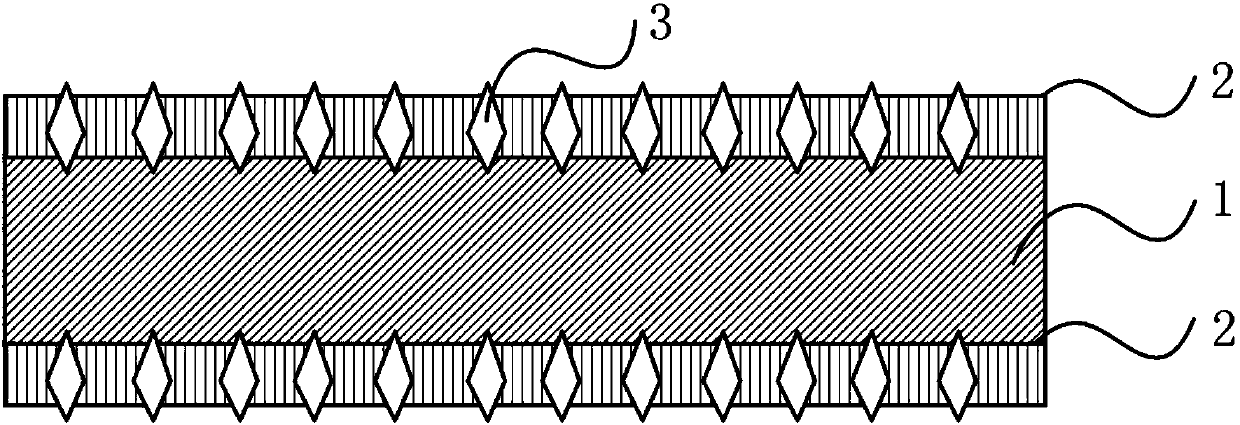

[0046] A composite oil-absorbing cotton for cleaning oily spots on water, comprising an oil-absorbing cotton body 10, the oil-absorbing cotton body 10 comprising an oil-absorbing layer 1 and a hydrophilic film layer 2 fixed on the oil-absorbing layer 1, the hydrophilic film The material of layer 2 is non-woven fabric composited with polyester and wood pulp fiber, the material of the oil-absorbing layer 1 is polypropylene, and the hydrophilic film layer 2 is provided with several oil seepage holes 3 .

[0047] Further, as figure 2 As shown, the number of the hydrophilic film layer 2 is two layers, which are respectively fixed on the upper surface and the lower surface of the oil-absorbing layer 1, so as to ensure more fully absorbing the oil spray on the water surface.

[0048] Further, the material of the hydrophilic film layer 2 is a spunlace non-woven fabric composed of polyester and wood pulp fibers.

[0049] The grammage of spunlace nonwovens is generally lower than that...

Embodiment 3

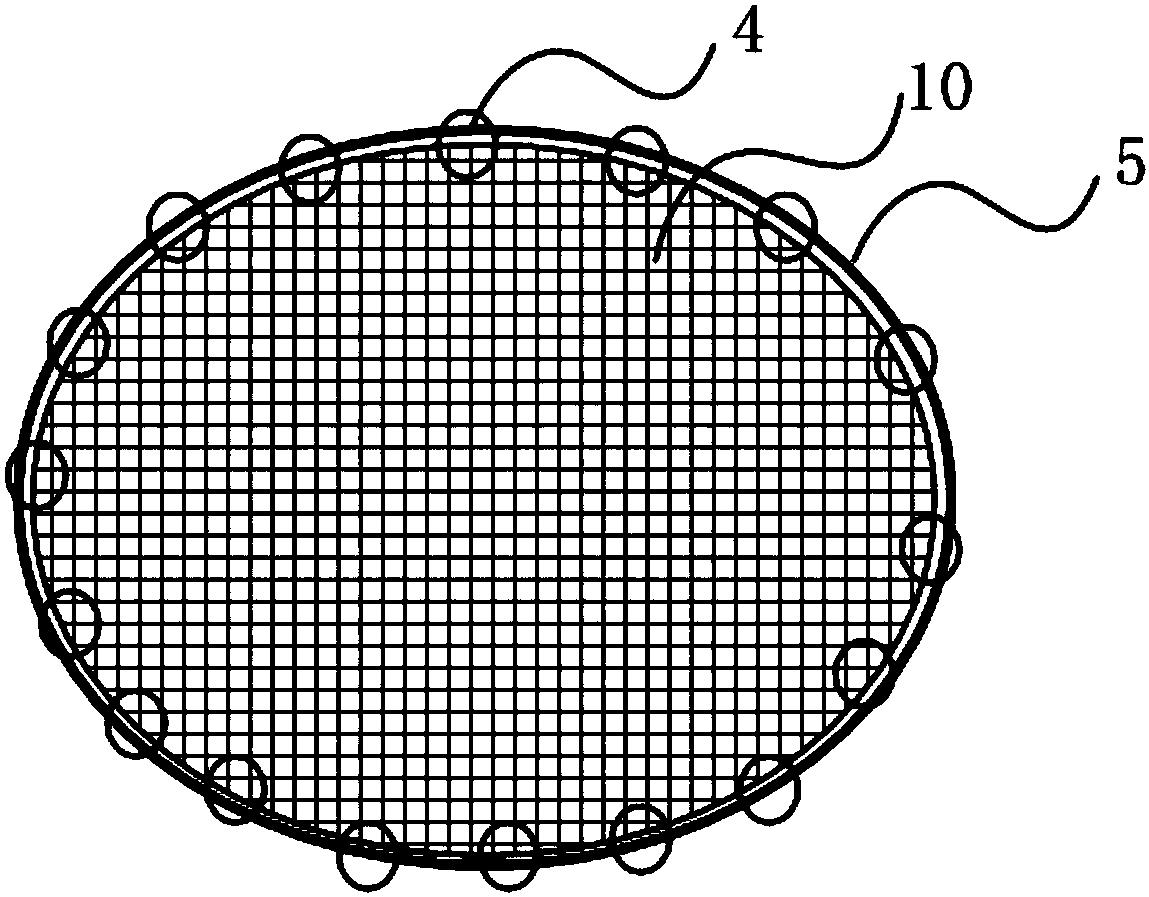

[0055] A composite oil-absorbing cotton for cleaning oily spots on water, comprising an oil-absorbing cotton body 10, the oil-absorbing cotton body 10 comprising an oil-absorbing layer 1 and a hydrophilic film layer 2 fixed on the oil-absorbing layer 1, the hydrophilic film The material of layer 2 is non-woven fabric composited with polyester and wood pulp fiber, the material of the oil-absorbing layer 1 is polypropylene, and the hydrophilic film layer 2 is provided with several oil seepage holes 3 .

[0056] Further, the number of the hydrophilic film layer 2 is two layers, which are respectively fixed on the upper surface and the lower surface of the oil-absorbing layer 1, so as to ensure more fully absorbing the oil spray on the water surface.

[0057] Further, the material of the hydrophilic film layer 2 is a spunlace non-woven fabric composed of polyester and wood pulp fibers.

[0058] Further, the oil-absorbing layer 1 is a sparse porous structure with a pore size of 50-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com