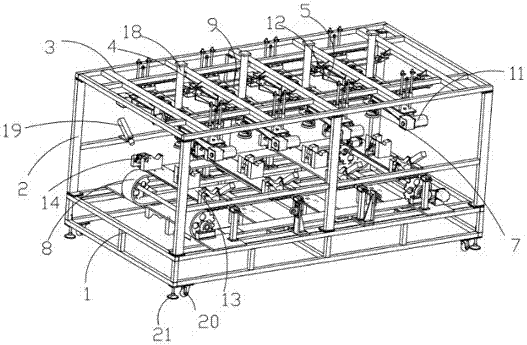

Automatic surface processing machine

A curved surface processing, fully automatic technology, applied in the direction of metal processing machinery parts, metal processing, metal processing equipment, etc., can solve the problems of high manufacturing cost, easy failure of equipment, increase of production cost of enterprises, etc., to simplify processing equipment, reduce Production cost, the effect of surface processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

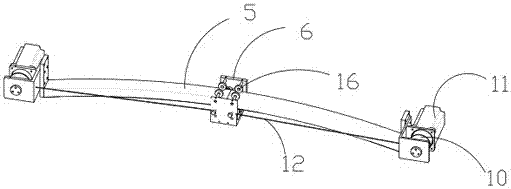

[0028] Embodiment one: if image 3 As shown, in order to reduce the friction between the slider 6 and the curved slide rail 5, reduce the wear of the curved slide rail 5, thereby ensuring the forming effect of the curved surface processing, a Some rubberized wheels 16 are arranged.

Embodiment 2

[0029] Embodiment two: if Figure 4 As shown, in order to reduce the friction between the sliding member 6 and the curved surface slide rail 5, reduce the wear of the curved surface slide rail 5, thereby ensuring the forming effect of the curved surface processing, the difference from the first embodiment is that the sliding member 6 and the Several balls 17 are arranged between the curved slide rails 5 .

[0030] The preferred implementation mode in this embodiment is that the processing device 7 is a grinding machine, a polishing machine, a cutting machine or a painting device, that is, the workpiece can be ground, polished, cut and painted. Different processing equipment can be placed in different positions to realize one-time molding of the workpiece. In addition, it can also be multi-pass processing for each process. sanding etc.

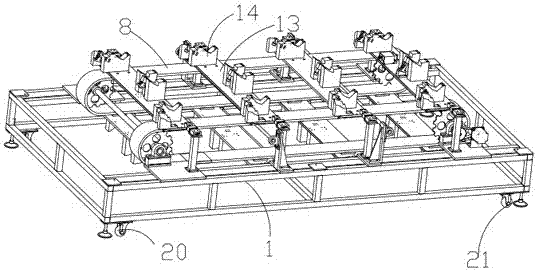

[0031] In order to be able to process products of different heights, and in addition to provide enough avoidance space for the workpiece tur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com