Steel bar bender for building construction

A technology for steel bar bending and building construction, applied in the field of steel bar bending machines for building construction, can solve the problems of poor structural stability, inconvenient carrying, complex structure, etc., and achieve the effects of easy installation and disassembly, firm and reliable installation, and stable and reliable structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

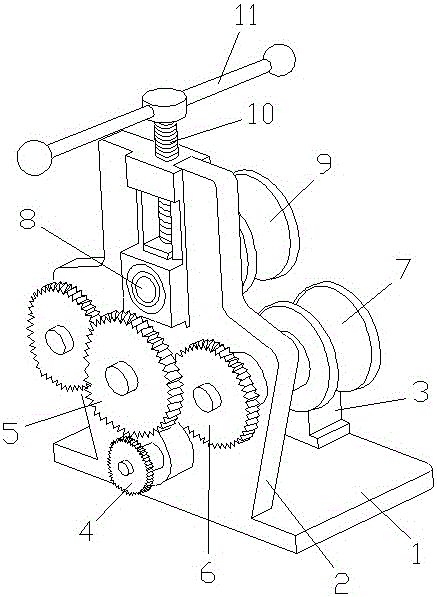

[0014] Such as figure 1 As shown, a steel bar bending machine for building construction includes a base 1, a locking sleeve 2, a hydraulic cylinder 3 and a piston rod 4. The locking sleeve 2 is arranged on the base 1, and the locking sleeve 2 and the base 1 Welding, the hydraulic cylinder 3 is set in the locking sleeve 2, the hydraulic cylinder 3 is clamped and connected with the locking sleeve 2, the locking sleeve 3 is provided with a fixing screw 5, and the piston rod 4 is set in the hydraulic pressure In the cylinder 3, the front end of the piston rod 4 is provided with a slider 6, the front end of the slider 6 is arranged in an arc shape, the two ends of the base 1 are equipped with rollers 7, and the middle part of the roller 7 is provided with a rotating shaft 8. The rotating shaft is welded to the base 1 , and the hydraulic cylinder 3 is provided with a hydraulic interface 9 and a handle 10 .

[0015] The hydraulic interface 9 is provided with two, which is convenient...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com