Drying method of coffee beans

A drying method and technology for coffee beans, applied in application, food processing, food science and other directions, can solve problems such as loss of flavor substances or nutrients, and achieve the effects of inhibiting microbial indicators exceeding the standard, prolonging shelf life and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

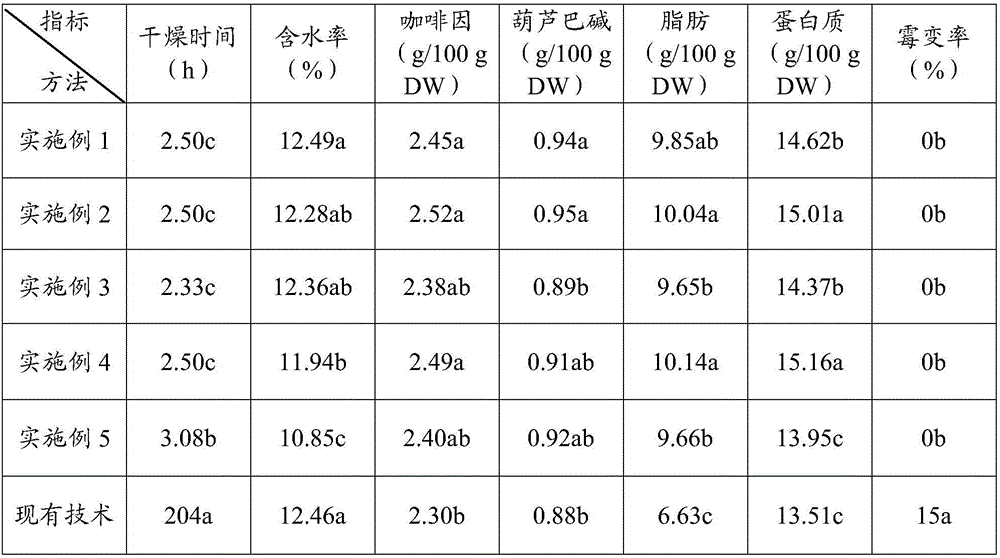

Examples

Embodiment 1

[0049] Embodiment 1: the method for preparing green coffee beans by microwave vacuum drying

[0050] The technical scheme adopted in the present invention is specifically implemented according to the following steps:

[0051] Using fresh coffee berries that are red, ripe, free of pests and mechanical damage as raw materials, the fresh coffee cherries are cleaned and removed to remove impurities such as residual berries and soil, and then the fresh coffee cherries after cleaning are placed in a continuous coffee peeling and degumming machine for removal The peel and pectin are drained to remove the moisture on the surface of the green coffee beans; then the green coffee beans are subjected to three-stage microwave vacuum drying, the vacuum degree is controlled to be ≤-0.08MPa, the drying temperature is 40°C, and the material thickness is 2cm. In the first stage, when the microwave power is 2kw, the drying time is 30min; in the second stage, when the microwave power is 1kw, the ...

Embodiment 2

[0052] Embodiment 2: the method for preparing green coffee beans by microwave vacuum drying

[0053] The technical scheme adopted in the present invention is specifically implemented according to the following steps:

[0054] Using fresh coffee berries that are red, ripe, free of pests and mechanical damage as raw materials, the fresh coffee cherries are cleaned and removed to remove impurities such as residual berries and soil, and then the fresh coffee cherries after cleaning are placed in a continuous coffee peeling and degumming machine for removal The peel and pectin are drained to remove the moisture on the surface of the green coffee beans; then the green coffee beans are subjected to three-stage microwave vacuum drying, the vacuum degree is controlled to be ≤-0.08MPa, the drying temperature is 50°C, and the material thickness is 5cm. In the first stage, when the microwave power is 2kw, the drying time is 35min; in the second stage, when the microwave power is 1kw, the dr...

Embodiment 3

[0055] Embodiment 3: the method for preparing green coffee beans by microwave vacuum drying

[0056] The technical scheme adopted in the present invention is specifically implemented according to the following steps:

[0057] Using fresh coffee berries that are red, ripe, free of pests and mechanical damage as raw materials, the fresh coffee cherries are cleaned and removed to remove impurities such as residual berries and soil, and then the fresh coffee cherries after cleaning are placed in a continuous coffee peeling and degumming machine for removal The peel and pectin are drained to remove the moisture on the surface of the green coffee beans; then the green coffee beans are subjected to three-stage microwave vacuum drying, the vacuum degree is controlled to be ≤-0.08MPa, the drying temperature is 45°C, and the material thickness is 3cm. In the first stage, when the microwave power is 2kw, the drying time is 25min; in the second stage, when the microwave power is 1kw, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com