High-sugar feed for fattening pigs

A technology for fattening pigs and feed, applied in animal feed, animal feed, application and other directions, can solve the problems of difficulty in achieving the ratio of fine to rough feed, increase labor costs, time-consuming and laborious, etc., to improve disease resistance, promote large intestine motility, Nutrient complete effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A high-sugar fattening pig feed, made of the following raw materials in weight ratio: 10% sweet sorghum flour, 10% corn flour, 20% straw powder, 25% bagasse, 0.8% vinegar grains, 15% bran, chlorinated Choline 0.2%, microbial additive 0.5%, bean cake 2%, perilla cake 1%.

[0021] The fineness of described sweet sorghum flour and corn flour is 120 mesh, and water content is 10%.

[0022] The straw powder is blended from corn straw powder, sorghum straw powder and buckwheat straw powder, and the mixing ratio is: corn straw powder: sorghum straw powder: buckwheat straw powder=2:5:1.

[0023] The straw powder has a fineness of 70 mesh and a water content of ≤12%.

[0024] The vinegar grains are a blended dry fine powder with a fineness of 100 mesh, a water content of ≤5%, and 15% coarse flour added.

[0025] The microbial additive is a mixture of Escherichia coli and lactic acid bacteria, wherein the total number of live bacteria is >1.0×10 9 CPU / g.

Embodiment 2

[0027] A high-sugar fattening pig feed, made of the following raw materials in weight ratio: 13% sweet sorghum flour, 12% corn flour, 35% straw powder, 35% bagasse, 1.2% vinegar grains, 18% bran, chlorinated Choline 0.3%, microbial additive 0.6%, bean cake 2.5%, perilla cake 2.2%.

[0028] The fineness of described sweet sorghum flour and corn flour is 135 mesh, and the water content is 9%.

[0029] The straw powder is blended from corn straw powder, sorghum straw powder and buckwheat straw powder, and the mixing ratio is: corn straw powder: sorghum straw powder: buckwheat straw powder=2:5:1.

[0030] The straw powder has a fineness of 90 mesh and a water content of ≤12%.

[0031] The vinegar grains are a blended dry fine powder with a fineness of 110 mesh, a water content of ≤5%, and 15% coarse flour added.

[0032] The microbial additive is a mixture of Escherichia coli and lactic acid bacteria, wherein the total number of live bacteria is >1.0×10 9 CPU / g.

Embodiment 3

[0034] A high-sugar fattening pig feed, made of the following raw materials in weight ratio: 15% sweet sorghum flour, 15% corn flour, 50% straw powder, 40% bagasse, 1.5% vinegar grains, 20% bran, chlorinated Choline 0.5%, microbial additive 0.7%, bean cake 3%, perilla cake 3%.

[0035] The fineness of the described sweet sorghum flour and corn flour is 150 mesh, and the water content is 10%.

[0036] The straw powder is blended from corn straw powder, sorghum straw powder and buckwheat straw powder, and the mixing ratio is: corn straw powder: sorghum straw powder: buckwheat straw powder=2:5:1.

[0037] The straw powder has a fineness of 100 mesh and a water content of ≤12%.

[0038] The vinegar grains are a blended dry fine powder with a fineness of 120 mesh, a water content of ≤5%, and 15% coarse flour added.

[0039] The microbial additive is a mixture of Escherichia coli and lactic acid bacteria, wherein the total number of live bacteria is >1.0×10 9 CPU / g.

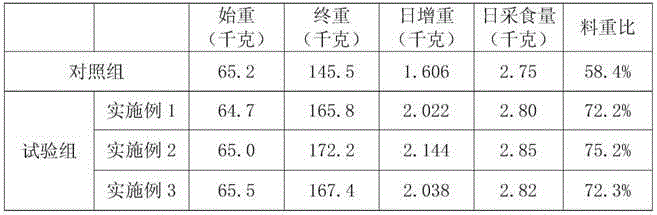

[0040] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com