Liquid crystal display element and method for producing same

A technology of liquid crystal display elements and liquid crystal molecules, applied in liquid crystal materials, chemical instruments and methods, optics, etc., can solve problems such as insufficient effects, and achieve the effects of less screen burn-in, excellent high-speed response, and less drop marks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

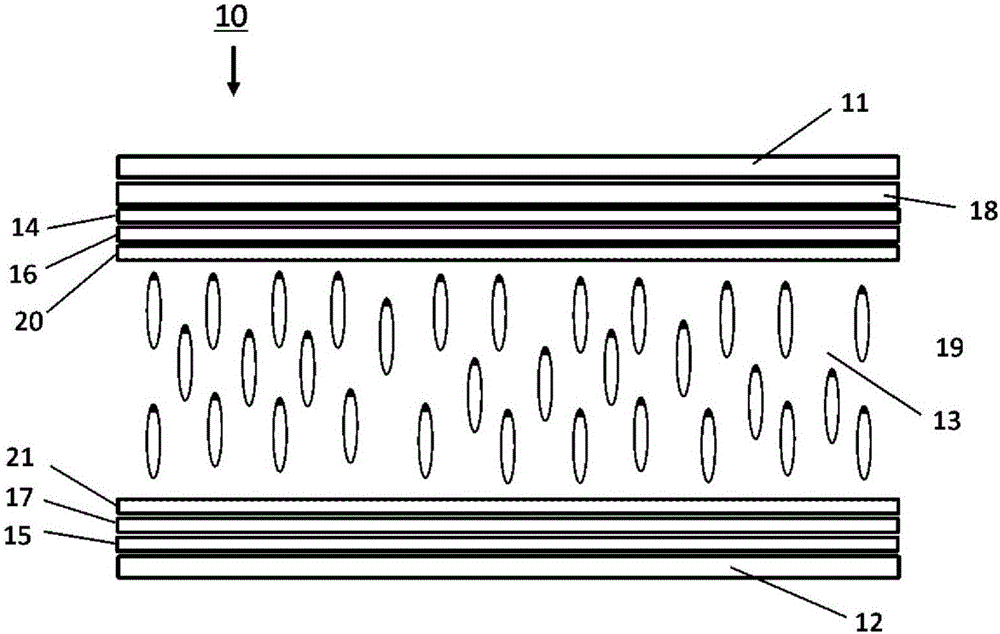

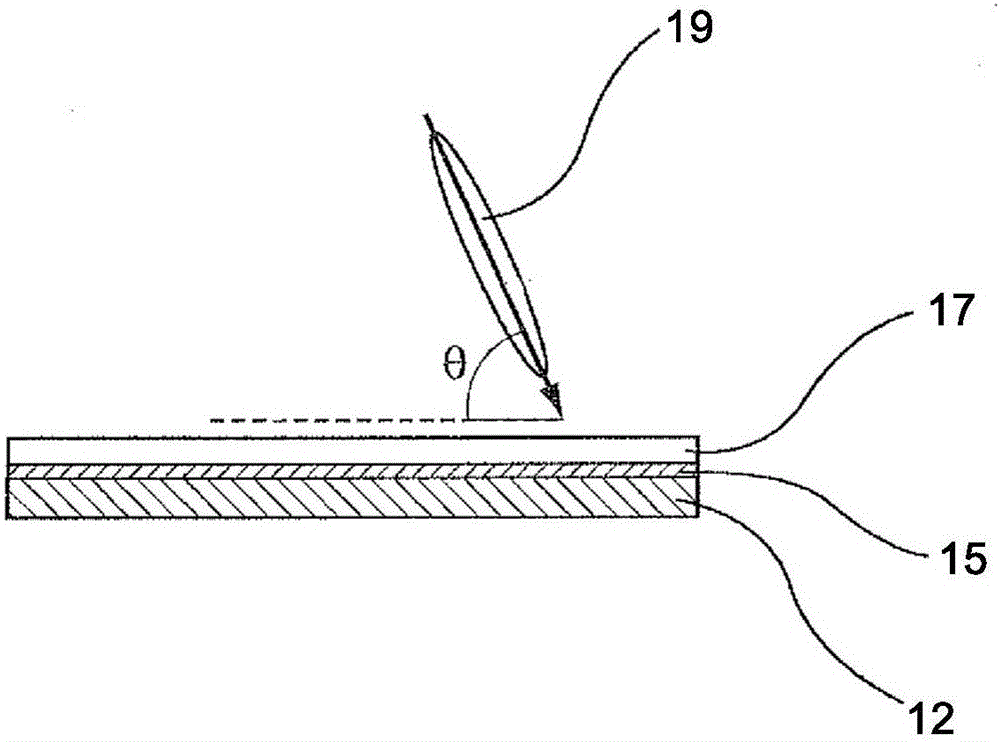

[0297] A first substrate (common electrode substrate) having a transparent electrode layer and a color filter layer, and a second substrate (pixel electrode substrate) having a pixel electrode layer are prepared, wherein the transparent electrode layer includes a transparent common electrode, and the pixel electrode layer has transparent pixel electrodes driven by active elements.

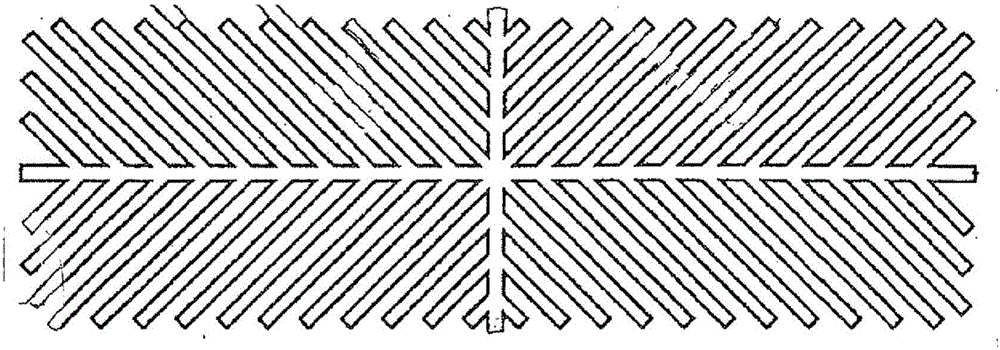

[0298] In the pixel electrode substrate, as each pixel electrode, a pixel electrode obtained by etching ITO is used so that a slit having no electrode exists in the pixel electrode in order to divide the alignment of liquid crystal molecules.

[0299] Coating a vertical alignment film material comprising a polyimide precursor and a polymerizable compound having a reactive group on the common electrode substrate and the pixel electrode substrate by spin coating, and heating the coating film at 200°C, Thus, the polyimide precursor in the vertical alignment film material was cured, and a vertical alig...

Embodiment 2

[0340] As a material for forming a vertical alignment film, a polyimide solution (trade name: JALS2131-R6; manufactured by JSR Corporation) containing 3% of a polyimide precursor containing 2% of the formula (V-2) is used. A polymerizable compound having a reactive group and 1% of a solution of a polymerizable compound having a reactive group represented by the following formula (VI-2), except that, the same operation as in Example 1 was performed to obtain Common electrode substrate and pixel electrode substrate with vertical alignment film.

[0341] [chem 34]

[0342]

[0343] To 99.7% of the liquid crystal composition used in Example 1, 0.3% of a polymerizable compound represented by the general formula (V-2) was added to prepare a liquid crystal composition containing a polymerizable compound, which was sandwiched between the formed Between the common electrode substrate of the vertical alignment film and the pixel electrode substrate, the liquid crystal display elemen...

Embodiment 3

[0349] As a vertical alignment film forming material, a polyimide solution (trade name: JALS2131-R6; manufactured by JSR Corporation) containing 2% of the following formula (V-4a) containing 3% of a polyimide precursor was used. The polymerizable compound with the reactive group shown and the solution containing 1% of the polymerizable compound with the reactive group represented by the formula (VI-1), except that, it was operated in the same manner as in Example 1 to obtain A common electrode substrate and a pixel electrode substrate having a vertical alignment film are formed.

[0350] [chem 35]

[0351]

[0352] To 99.7% of the liquid crystal composition used in Example 1, 0.3% of a polymerizable compound represented by the general formula (V-2) was added to prepare a liquid crystal composition containing a polymerizable compound, which was sandwiched between the formed Between the common electrode substrate of the vertical alignment film and the pixel electrode substra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com