Multi-nozzle cascade type plasma jet-triggered high-voltage switch

A high-voltage switch, plasma technology, applied in the direction of plasma, electrical components, reactive power adjustment/elimination/compensation, etc., can solve the problems of limited range and the gap length can not be too long, to balance reactive power, improve work Voltage, reliable triggering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

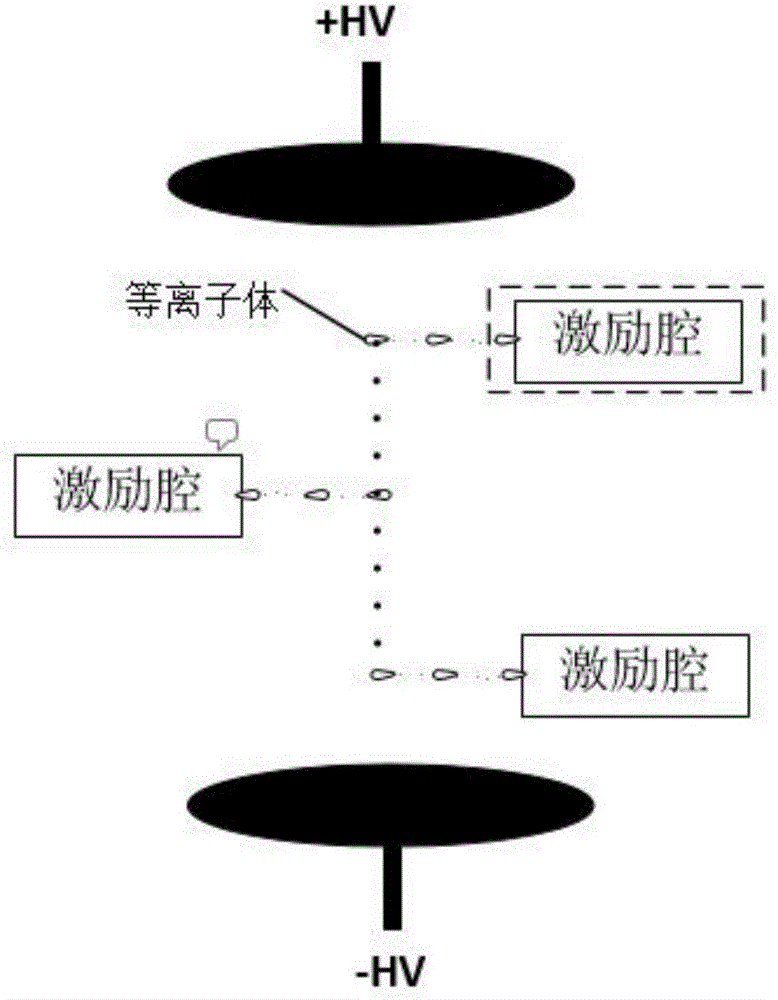

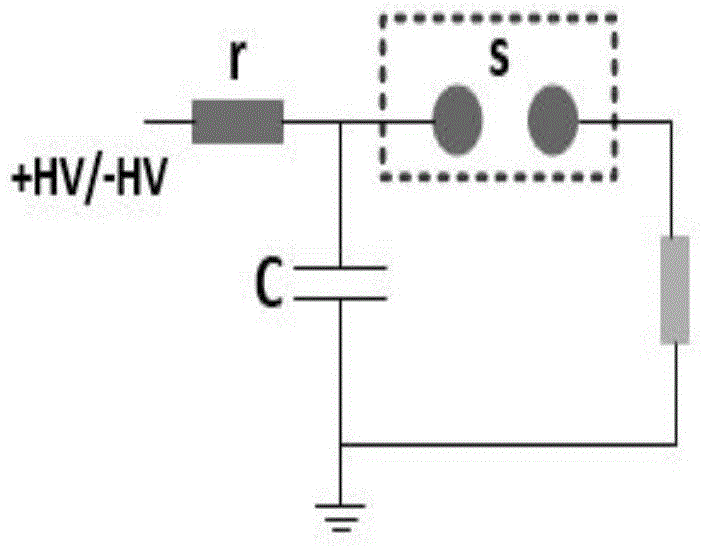

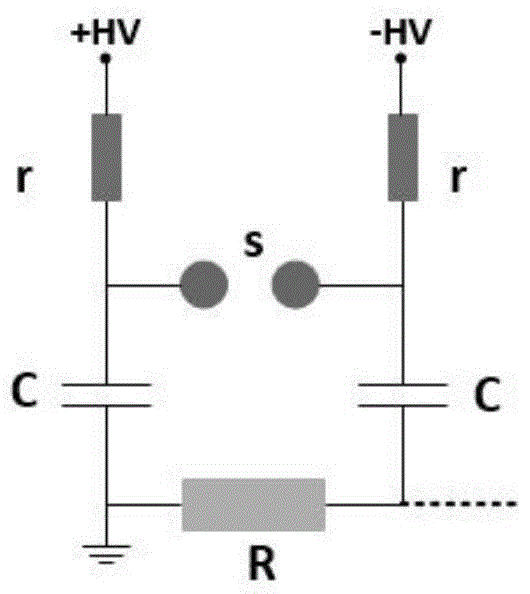

[0010] Attached below figure 1 -2 and specific embodiment further illustrate the concrete content of this invention:

[0011] In one embodiment, the present invention discloses a multi-nozzle cascade plasma injection trigger high voltage switch;

[0012] The high-voltage switch includes a plurality of excitation cavities distributed around the main electrode gap of the high-voltage switch for injecting plasma.

[0013] The number of excitation cavities in this embodiment is related to the working voltage of the switch. The higher the working voltage of the switch, the longer the gap, the higher the resistance point strength of the main gap, and the more the number of excitation cavities. Therefore, the specific number needs to be determined according to the actual situation. To decide.

[0014] In this embodiment, a cascaded plasma injection trigger high-voltage switch is designed. The polarity arrangement of the switch electrodes is flexible, and the multi-channel plasma in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com