Coil static electromagnetic eddy current speed regulator

An electromagnetic eddy current and governor technology, applied in the direction of electric brakes/clutches, electrical components, electromechanical devices, etc., can solve the problems of high power difficult to dissipate heat, permanent magnet high temperature demagnetization, can not meet the needs of high power, etc., to achieve motion High reliability, noise pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

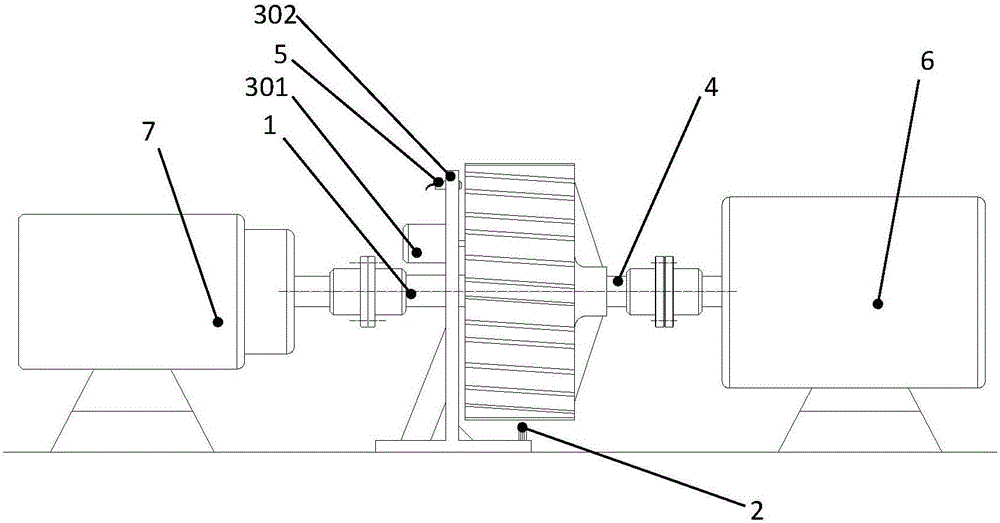

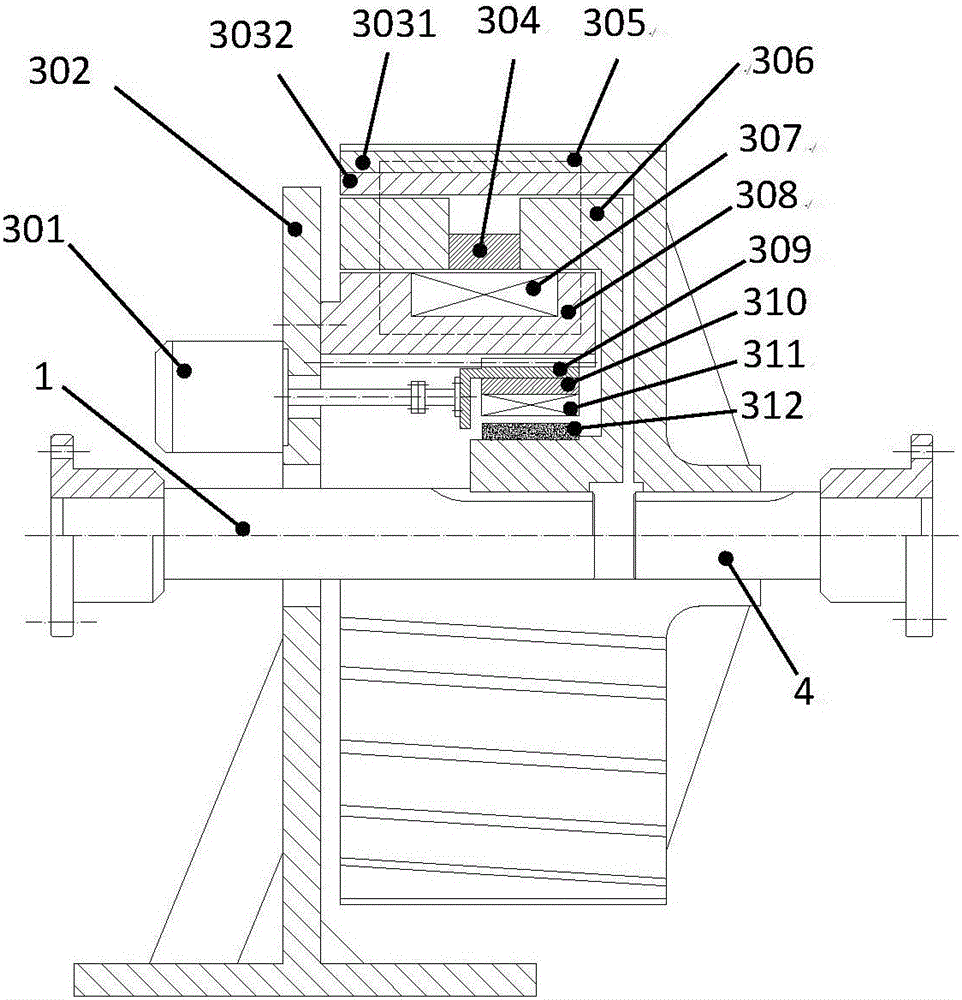

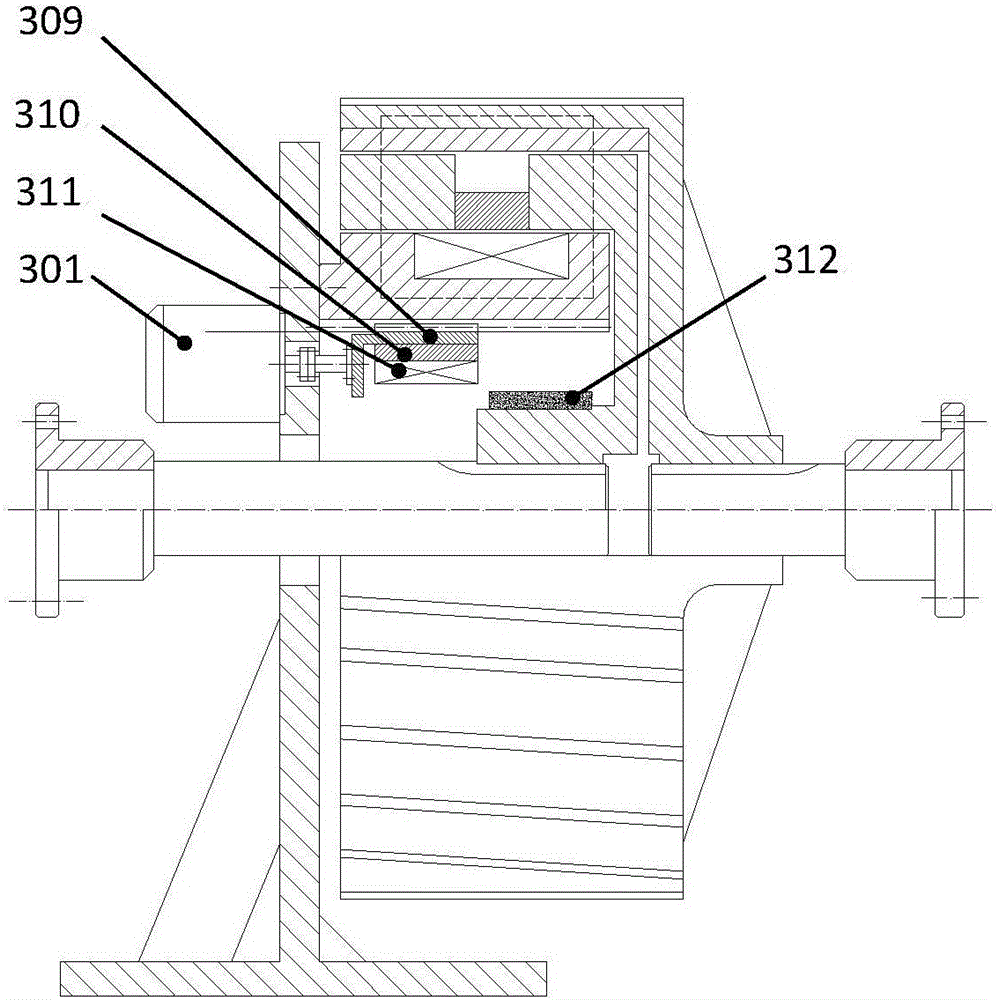

[0035] A static coil type electromagnetic eddy current governor, comprising a motor input shaft 1, a temperature sensor 2, a control motor 301, a stator bracket 302, an outer rotor 303, a magnetic isolation ring 304, a magnetic circuit 305, an inner rotor 306, an excitation coil 307, Stator 308, generator silicon steel sheet 309, spline shaft 310, generator armature 311, generator permanent magnet 312, load output shaft 4, speed sensor 5, load 6, drive motor 7; the outer rotor 303 and load The output shaft 4 is connected, and the outer rotor 303 has inner and outer layers. The outer layer of the outer rotor 303 is an outer rotor A3031 of ferromagnetic material, and the inner layer of the outer rotor 303 is an outer rotor B3032 of a copper material.

[0036]The inner rotor 306 is connected with the motor input shaft 1, the inner rotor 306 adopts double salient pole tooth structure, a magnetic isolation ring 304 is arranged between the two salient poles, and the magnetic isolatio...

Embodiment 2

[0045] A static coil electromagnetic eddy current governor of the present invention is an external power supply structure, see Image 6 , remove the generator, replace the control motor with a current controller, directly provide current for the excitation coil through the current controller, the current controller (301) is fixed on the stator bracket (302), and connect the excitation coil (307 ) to directly supply power to the excitation coil (307), the structure of the external power supply is simpler and more convenient, but the disadvantage is that an external power supply is required and consumes part of the power.

[0046] The external power supply structure of the static coil electromagnetic eddy current governor proposed by the present invention is mainly composed of the following parts:

[0047] Motor input shaft, load output shaft, outer rotor (ferromagnetic material), outer rotor (copper material), inner rotor, stator, excitation coil, magnetic isolation ring, stato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com