A constant voltage output structural component and a rechargeable battery using the same

A technology of structural components and constant voltage output, which is applied in the direction of secondary batteries, cell structure combination, secondary battery repair/maintenance, etc., and can solve the constraints of secondary battery promotion and replacement use, difficulty in controlling the appearance of battery packaging products, and packaging technology Complexity and other issues, to achieve high capacity, simple and efficient assembly process, and reduce process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Taking the production of a cylindrical rechargeable battery with constant voltage output as an example, the structural components of constant voltage output are further described, and the structure of the cylindrical rechargeable battery with constant voltage output is also explained.

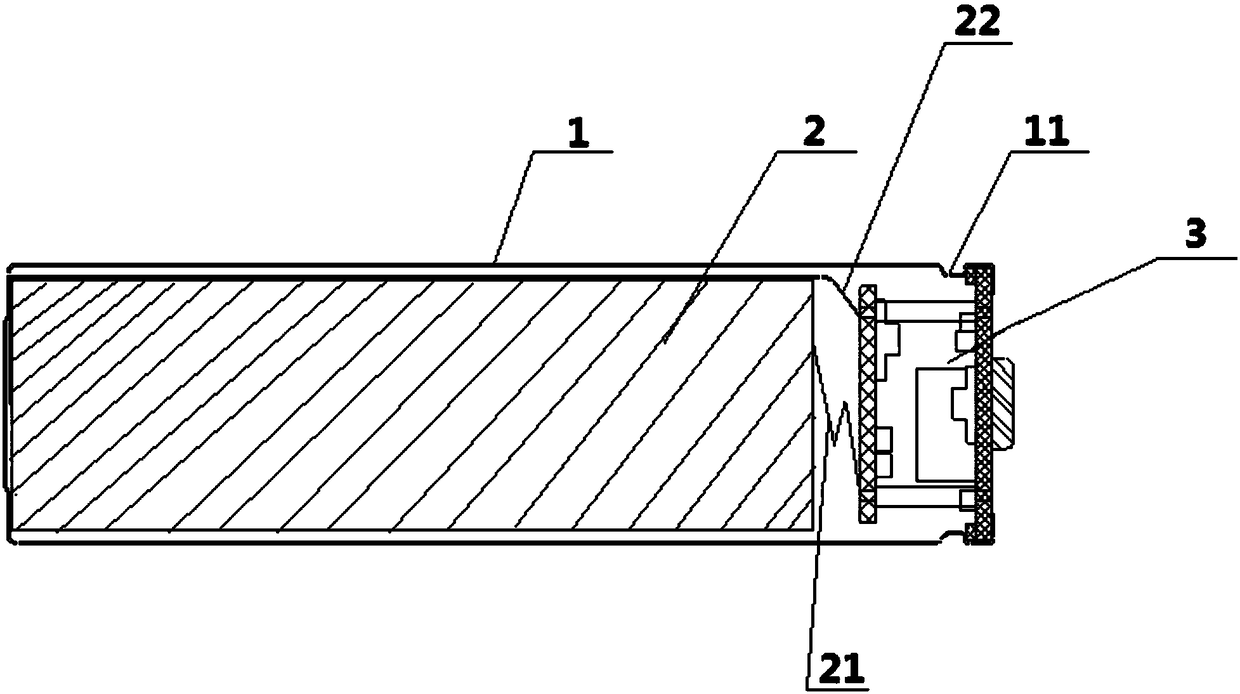

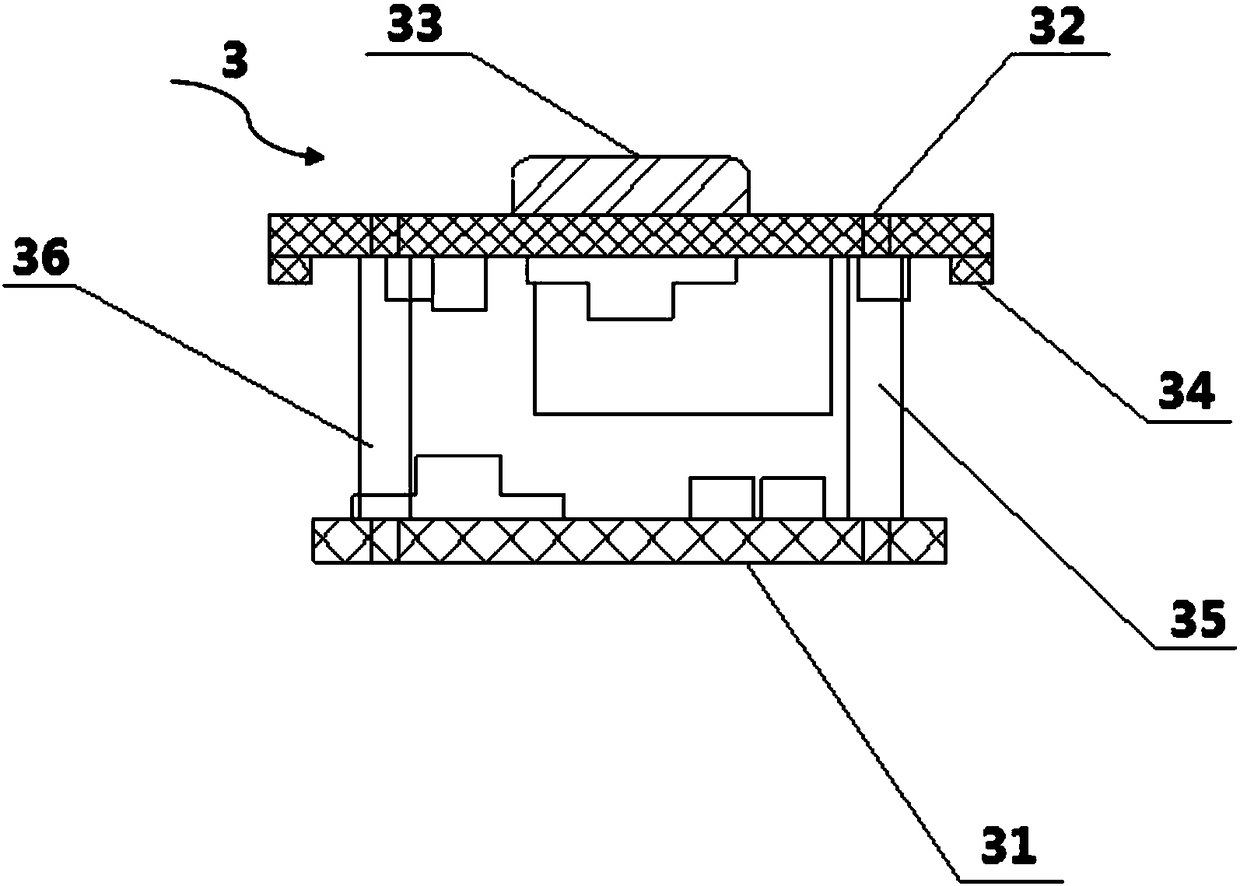

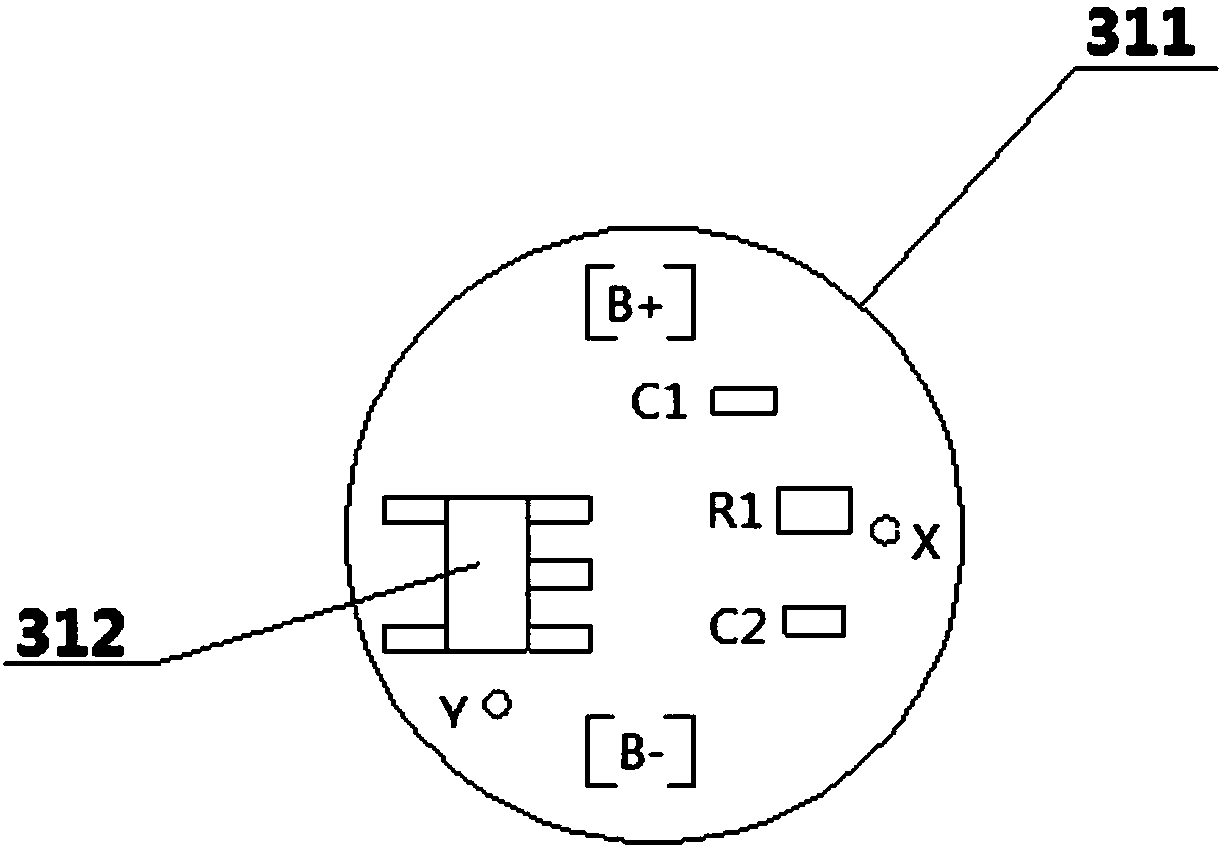

[0038] A rechargeable battery, which is cylindrical, and its requirements are: battery diameter ≤ 14.5mm, battery height ≤ 50.5mm, battery with charge and discharge protection function, battery with constant voltage 1.50V±0.10V, maximum current output function of 2A ,Such as figure 1 As shown, including shell 1, battery cell 2 and constant voltage output structural component 3, the battery cell of this embodiment is a polymer lithium ion single battery, its model is 13400 (diameter 13mm, height 40mm), and the nominal voltage is 3.6 V, the capacity is 650mAh; shell 1 is a steel shell, its outer diameter is 14.15±0.05mm, its inner diameter is 13.90±0.05mm, and its height is 51.0±0.05mm; T...

Embodiment 2

[0054] A cylindrical rechargeable battery with constant voltage output, its structure is similar to the structure of a cylindrical rechargeable battery with constant voltage output in Example 1, the difference is that the battery cell is composed of a positive electrode, a negative electrode, a diaphragm Formed by winding, the thickness of the first substrate is 0.8mm. The thickness of the second substrate is 1.2mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com