A kind of flash storage unit and manufacturing method

A technology for flash memory storage and manufacturing methods, which is applied to electrical components, semiconductor devices, circuits, etc., and can solve problems such as high power consumption of devices, low effective coupling capacitance between floating gate and control gate, and filling gaps in floating gates, so as to reduce power consumption , Improving the effect of erasing and writing speed and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

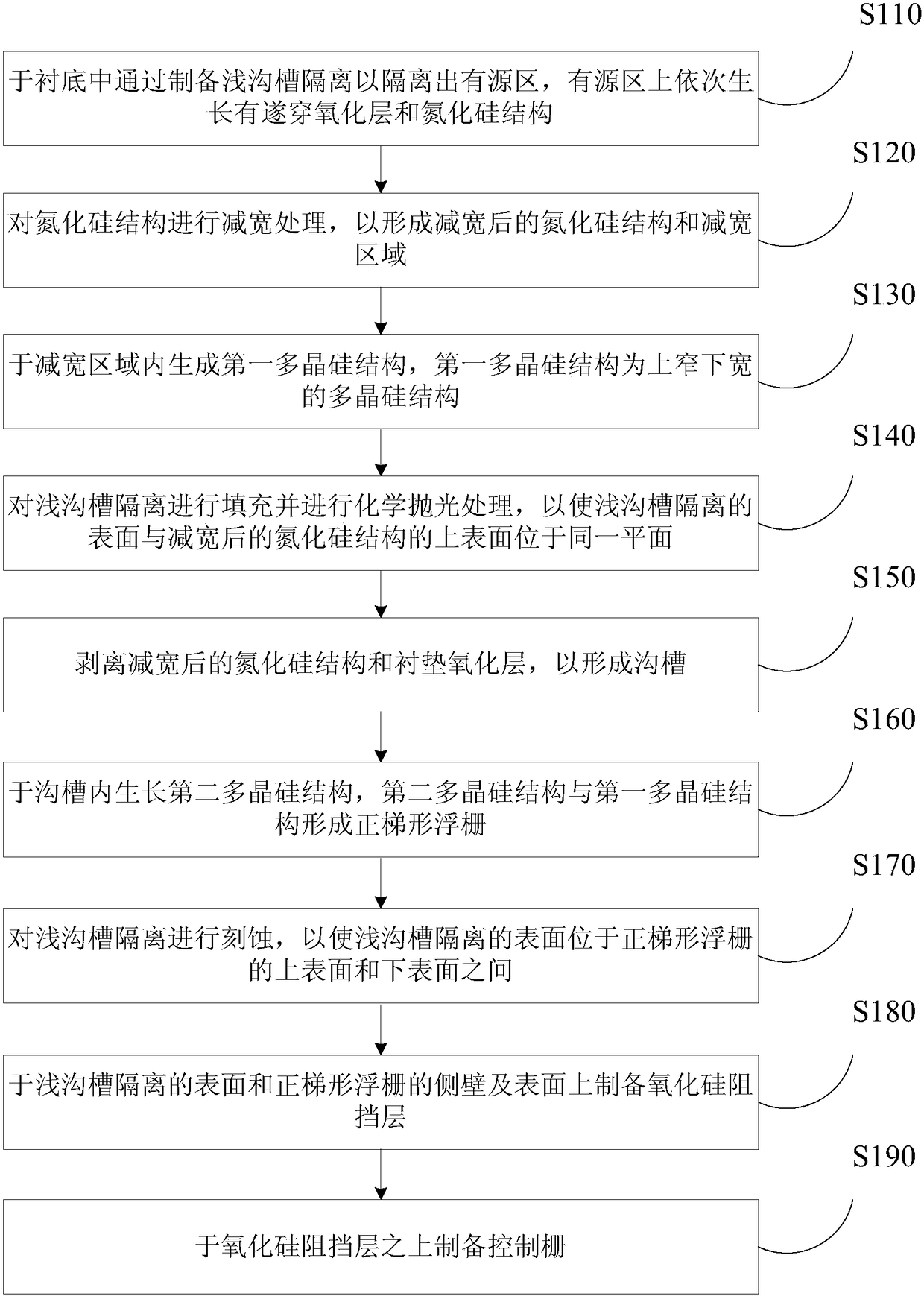

[0057] figure 2A flow chart of the method for manufacturing a flash storage unit provided in Embodiment 1 of the present invention is given. Such as figure 2 As shown, the method for manufacturing a flash memory storage unit provided in Embodiment 1 includes the following steps:

[0058] Step S110, isolating the active region 15 by preparing shallow trench isolation 14 in the substrate 10, on which the tunneling oxide layer 11 and the silicon nitride structure 12a are sequentially grown;

[0059] Specifically, such as Figure 3 to Figure 6 shown, refer to image 3 Firstly, a tunnel oxide layer 11 and a silicon nitride layer 12 are sequentially grown on the substrate 10, wherein the substrate 10 can be a silicon substrate, a silicon germanium substrate, a germanium substrate or a III-V compound substrate, In this embodiment, the substrate 10 is taken as a silicon substrate as an example. The material of the tunnel oxide layer 11 is preferably silicon oxide, and ion impla...

Embodiment 2

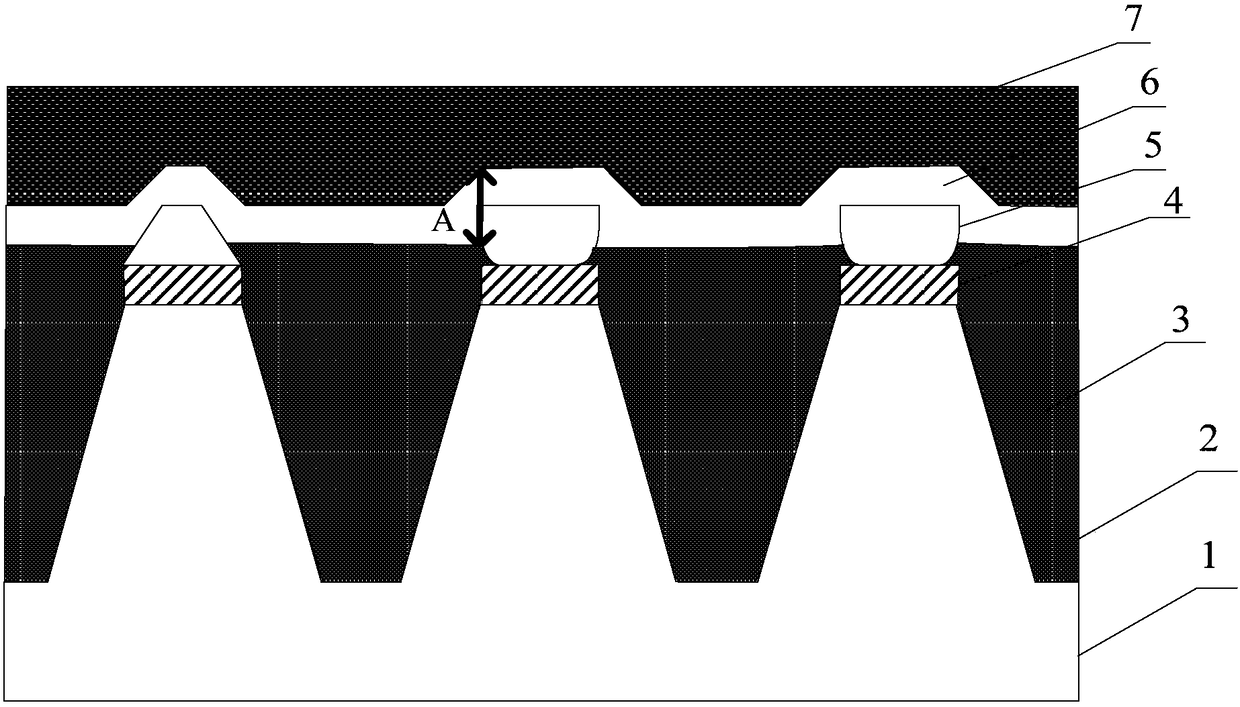

[0079] This embodiment provides a flash storage unit, such as Figure 16 shown, including:

[0080] a substrate 10, a plurality of shallow trenches 13 are formed on the upper part of the substrate 10;

[0081] tunneling the oxide layer 11, grown on the substrate 10;

[0082] a positive trapezoidal floating gate 19 formed on the tunnel oxide layer 11;

[0083] Shallow trench isolation 14, formed in the plurality of shallow trenches 13 and on the sidewalls of the positive trapezoidal floating gate 19;

[0084] a silicon oxide blocking layer 20 formed on the surface of the shallow trench isolation 14 and the sidewalls and the surface of the positive trapezoidal floating gate 19;

[0085] The control gate 21 is formed on the silicon oxide blocking layer 20 .

[0086] The flash memory storage unit provided in this embodiment uses floating gate etching technology to produce a positive trapezoidal floating gate structure. Due to the stability of the positive trapezoidal floating ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com