Automatic control system for high-frequency high voltage static dust-collecting power supply based on DSP+FPGA

An automatic control system and electrostatic precipitator technology, applied in the field of frequency conversion control, can solve the problems such as the acquisition speed can only reach tens of megabytes or hundreds of megabytes, the data acquisition speed cannot meet the fast control, and the external interface has poor versatility, etc., to achieve signal transmission. Accurate and reliable, improve stability and security, control the effect of timely response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

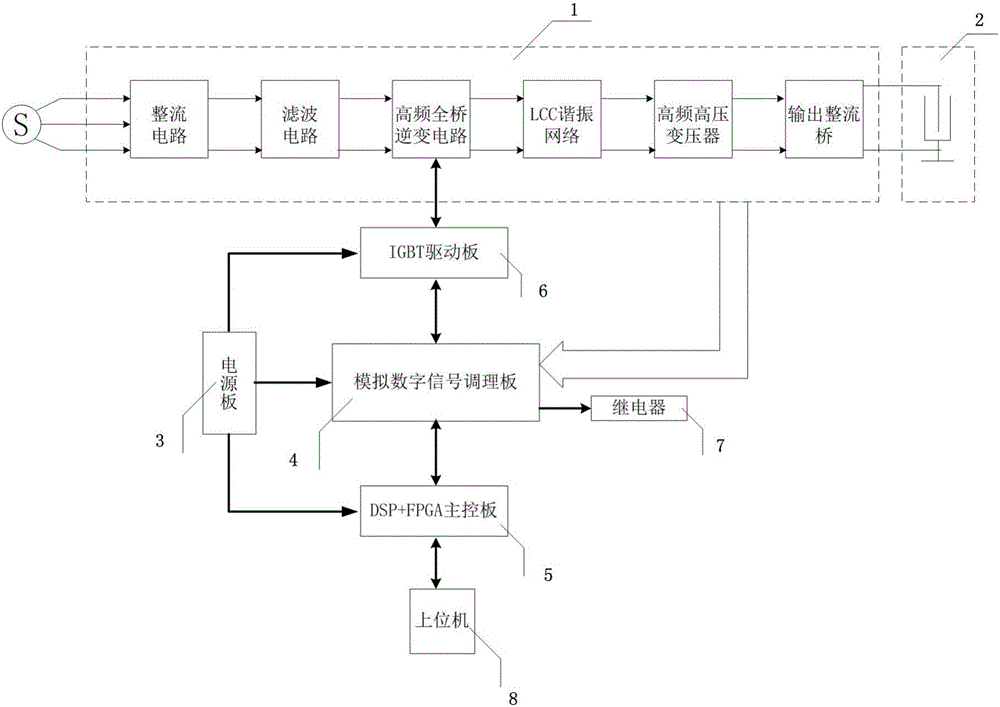

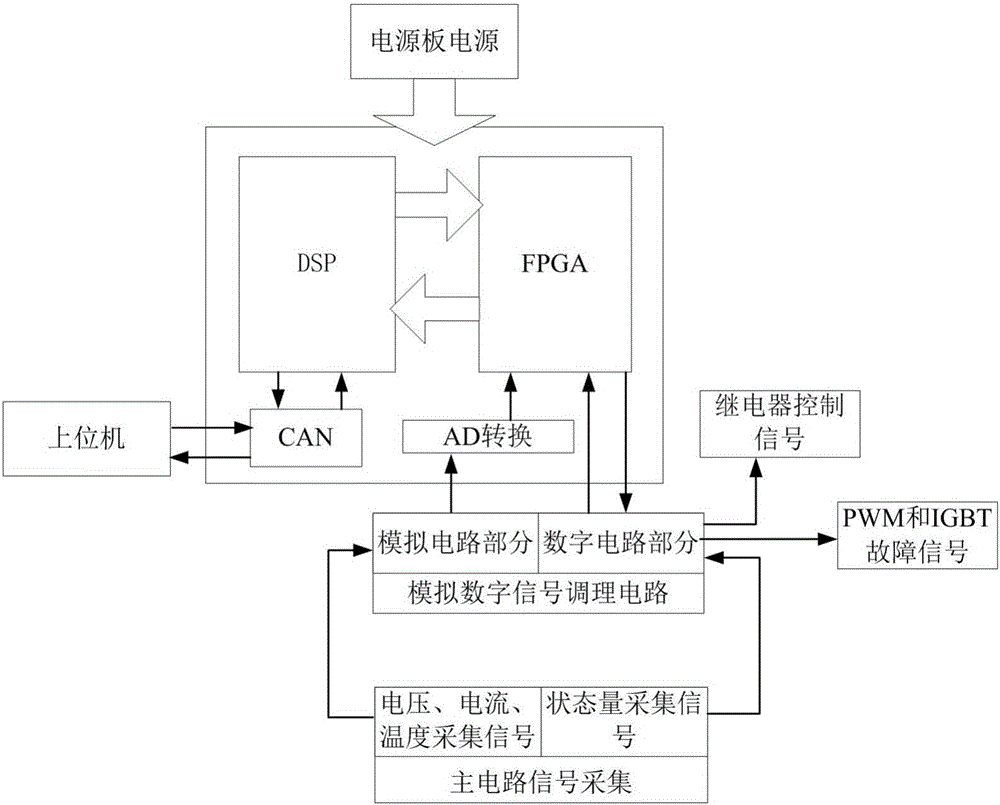

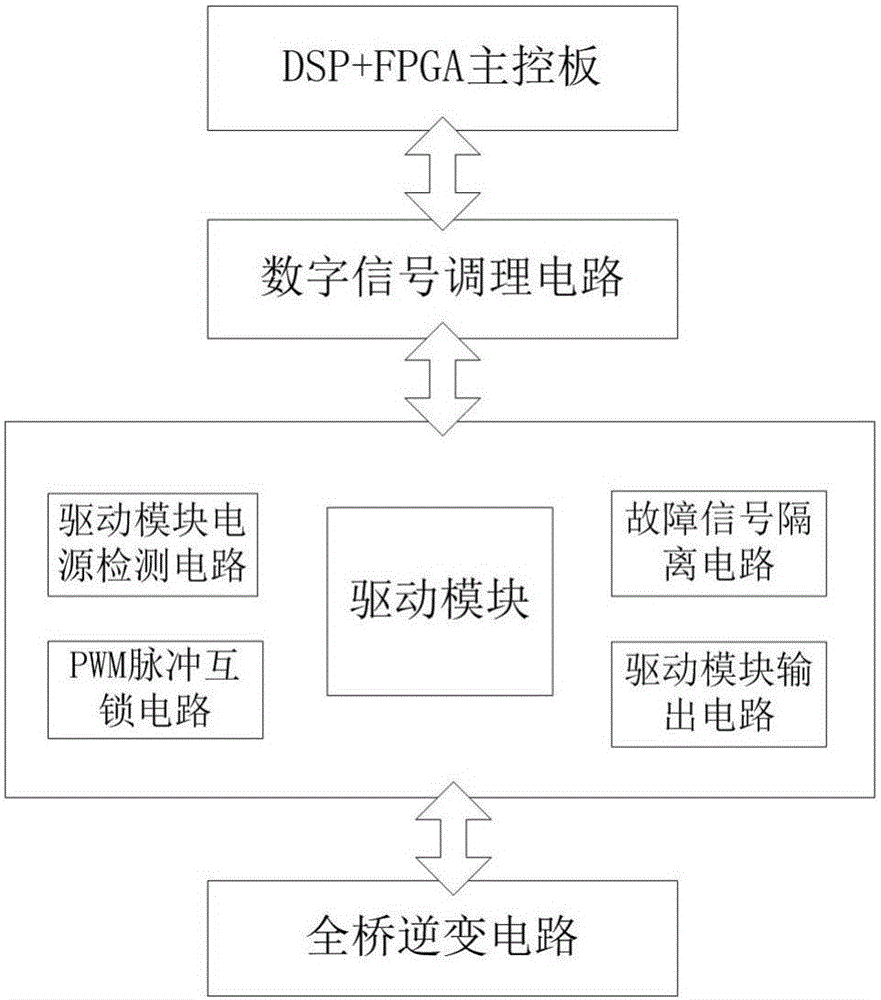

[0024] A high frequency and high voltage electrostatic precipitator power supply control system, see attached figure 1 , the system includes a power board 3, an analog and digital signal conditioning board 4, a DSP+FPGA main control board 5, an IGBT driver board 6 and an upper computer 8; the power board 3 supplies power to other circuit boards, and the signal conditioning board controls the main circuit of the electrostatic precipitator power supply Part 1 collects and adjusts the analog quantities (voltage, current and temperature) and digital quantities (closed state of the main circuit, high-voltage interlocking state, IGBT fault, etc.), and transmits all adjusted voltage analog quantities to the DSP+FPGA main control board 5. The DSP+FPGA main control board sends out PWM signals and relay control signals in combination with the collected informa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com