Flying needle test machine correction method

The technology of a flying probe testing machine and a calibration method, which is applied in the field of needle calibration, can solve the problems of mismeasurement, affecting the accuracy of the probe needle, and failing to tie the test point.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The invention provides an error correction method for a flying probe testing machine. The flying probe testing machine is equipped with a motor-driven probe on the X-Y axis that can move quickly and independently, and uses the controllable movement of the probe in the Z direction and is fixed on the machine. A device that makes contact with copper-plated holes on a PCB board and performs electrical measurements.

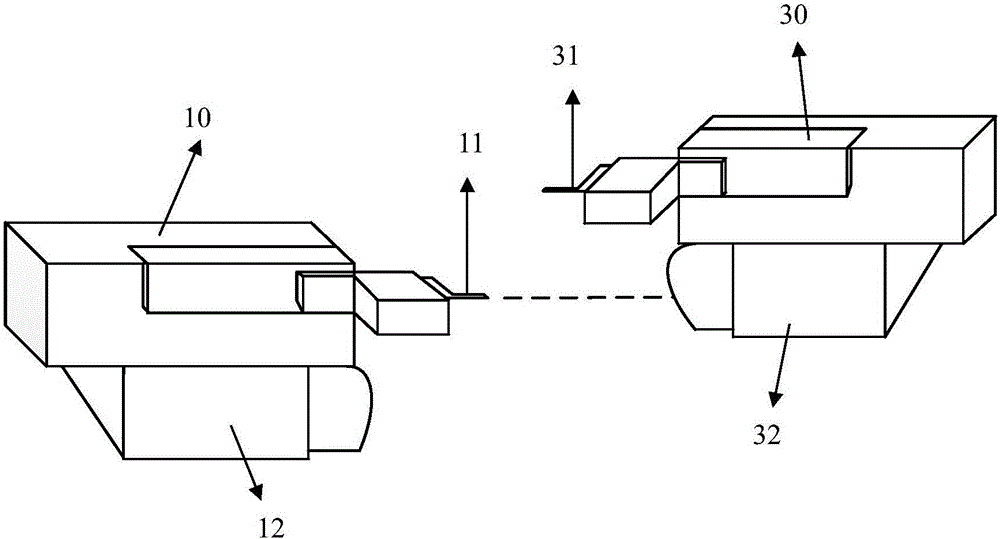

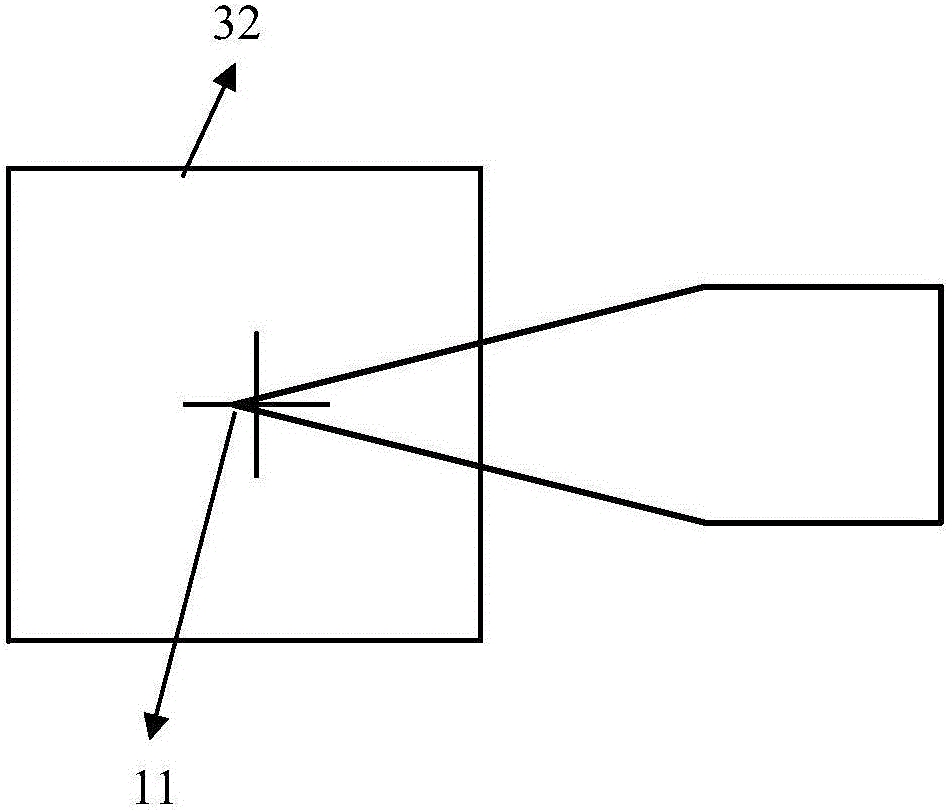

[0016] like figure 1 Shown is a schematic diagram of the local structure of the flying probe tester. The flying probe tester is provided with four test axes, namely: the first test axis 10, the second test axis (not shown), the third test axis 30, and The fourth test axis (not shown), wherein the first test axis 10 is provided with a first probe 11 and a first CCD camera 12, and the first CCD camera 12 is used to photograph the first probe on the first test axis 10 11 motion path and coordinates of the alignment point on the PCB board to be tested (printed ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com